Projector and method for cooling light source module discharging part

A technology for light source modules and discharge parts, which is applied in cooling/ventilation/heating renovation, optics, projection devices, etc., and can solve the problems of affecting service life, damage, and inability to control the condensation position of mercury vapor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

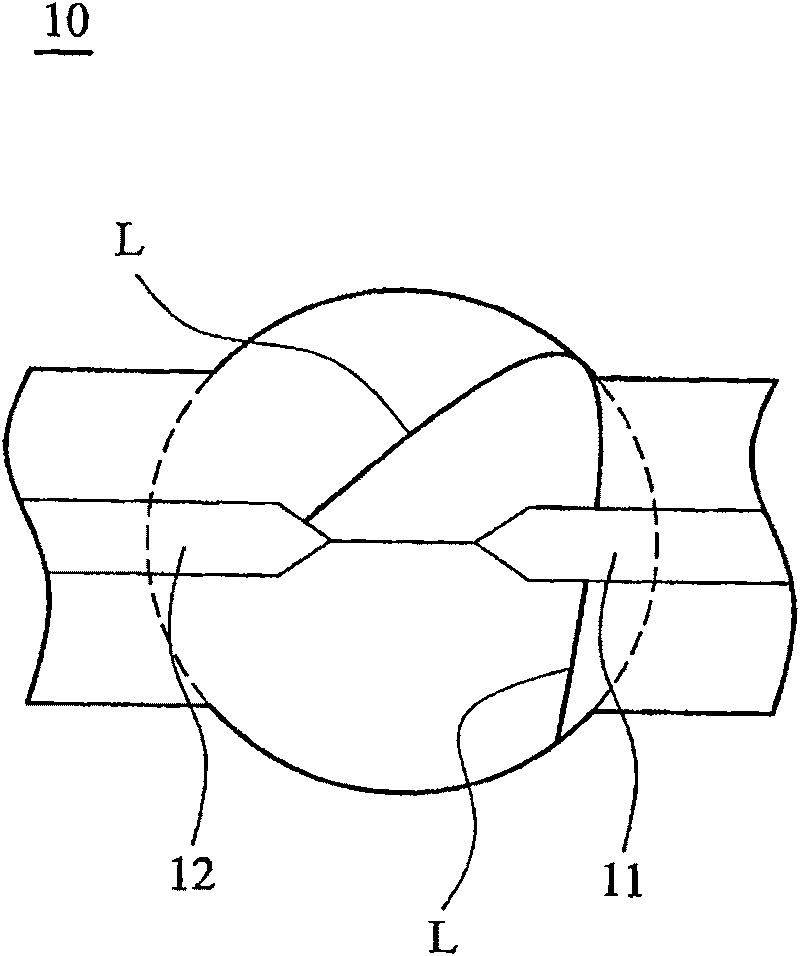

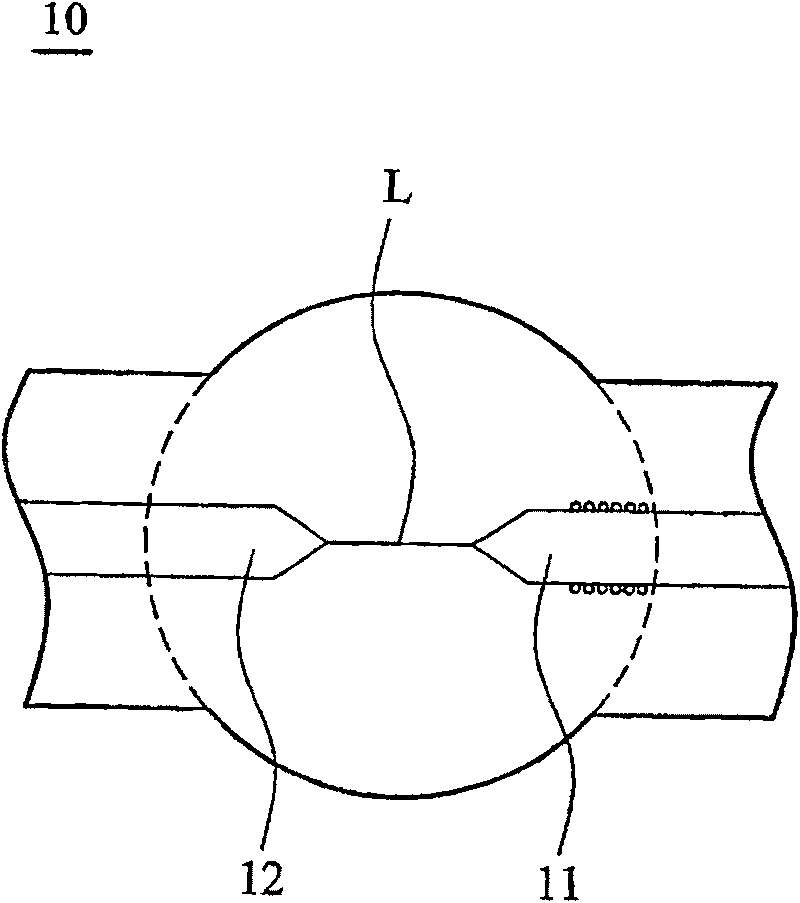

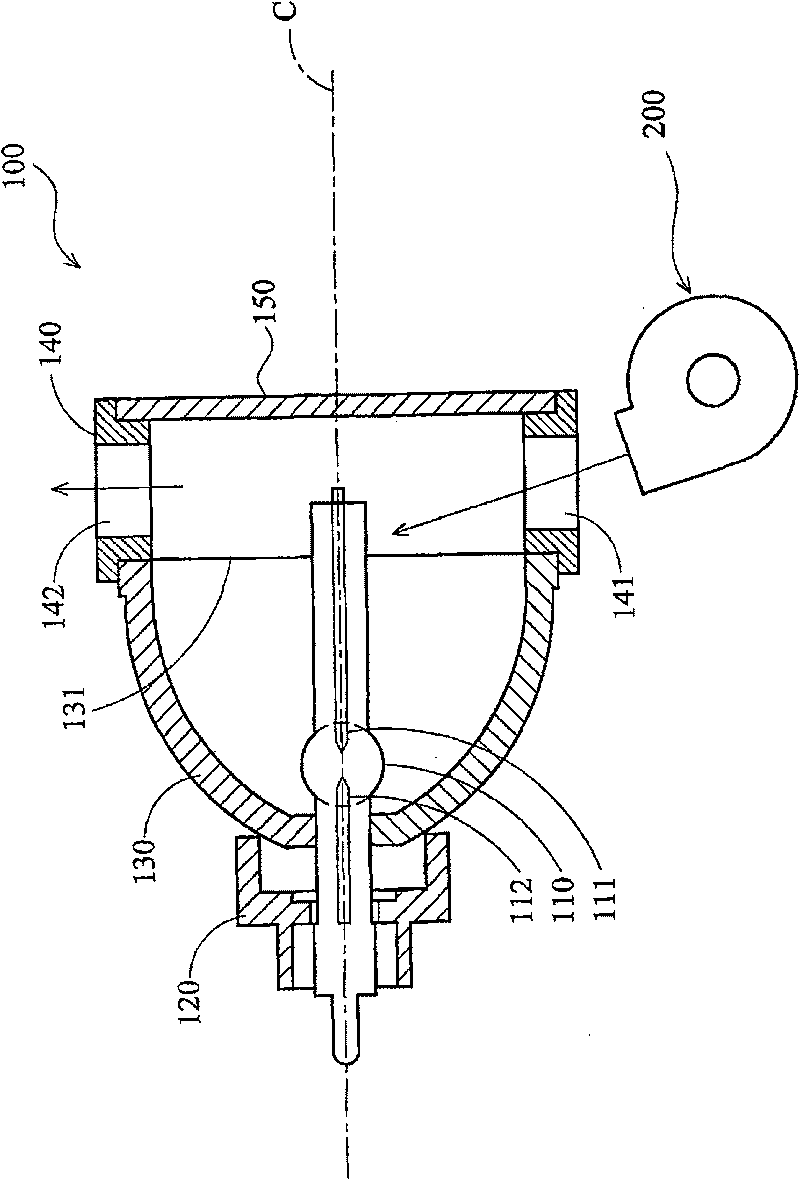

[0043] refer to Figure 2A , which shows a schematic diagram of the light source module 100 and the fan 200 inside the projector. The aforementioned light source module 100 is, for example, an ultra-high pressure mercury lamp, which mainly includes a discharge part 110, a base 120, a reflector 130, a flow guiding device 140, and a lens 150, wherein the discharge part 110 is located on the central axis C of the reflector 130 and is fixed to the base 120 , the aforementioned air guiding device 140 is connected to the reflector 130 and the lens 150 , and covers the opening 131 of the reflector 130 .

[0044] Such as Figure 2A As shown, the discharge portion 110 includes a first electrode 111 and a second electrode 112 made of metal, respectively serving as the cathode and anode of the discharge portion 110, wherein the first electrode 111 extends toward the opening 131 along the central axis C, and the second The second electrode 112 is opposite to the first electrode 111 . I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com