Cavity inner lining and reaction cavity

A reaction chamber and lining technology, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of lack of plasma uniformity, achieve the effect of protecting the side wall and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

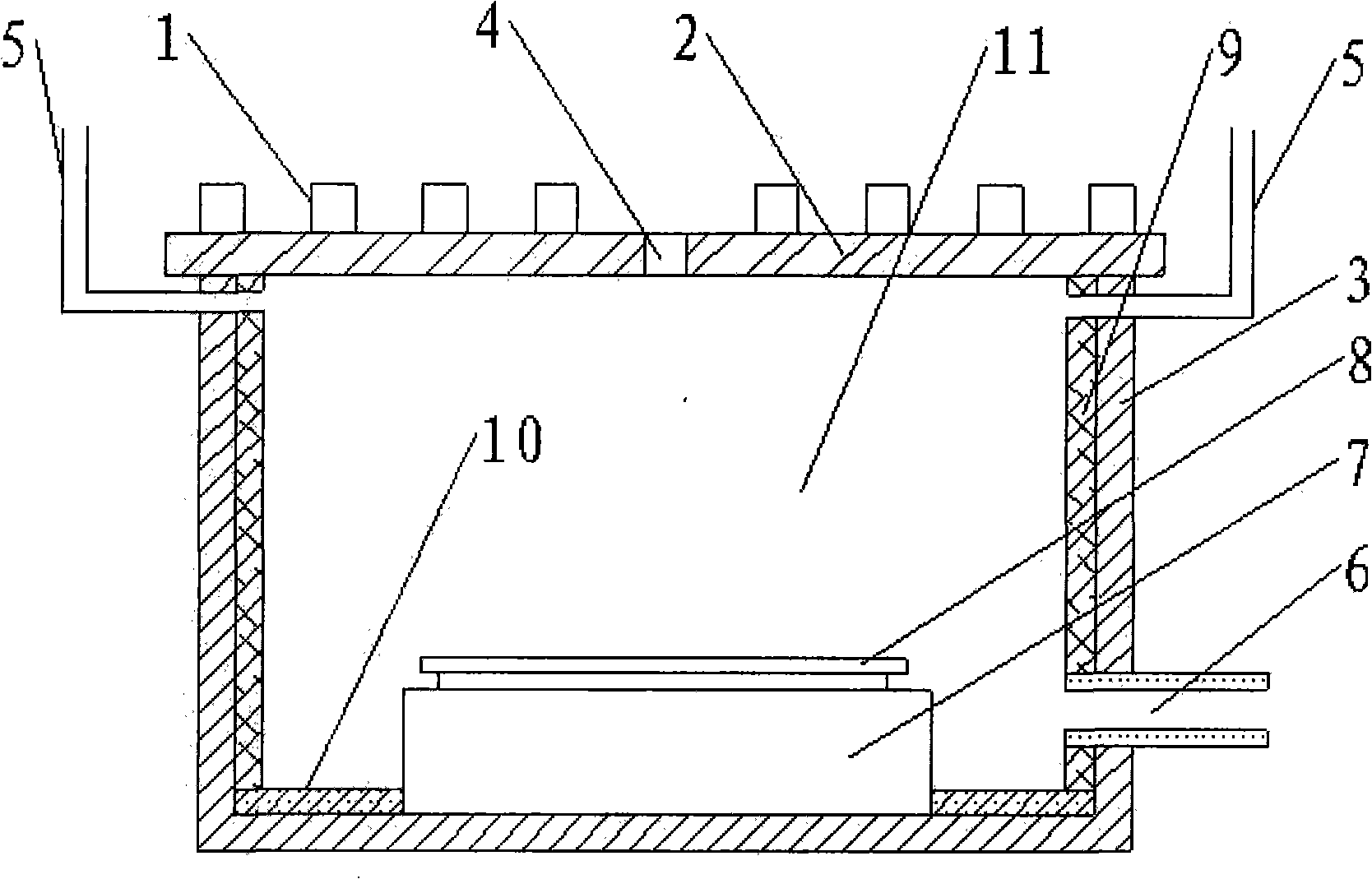

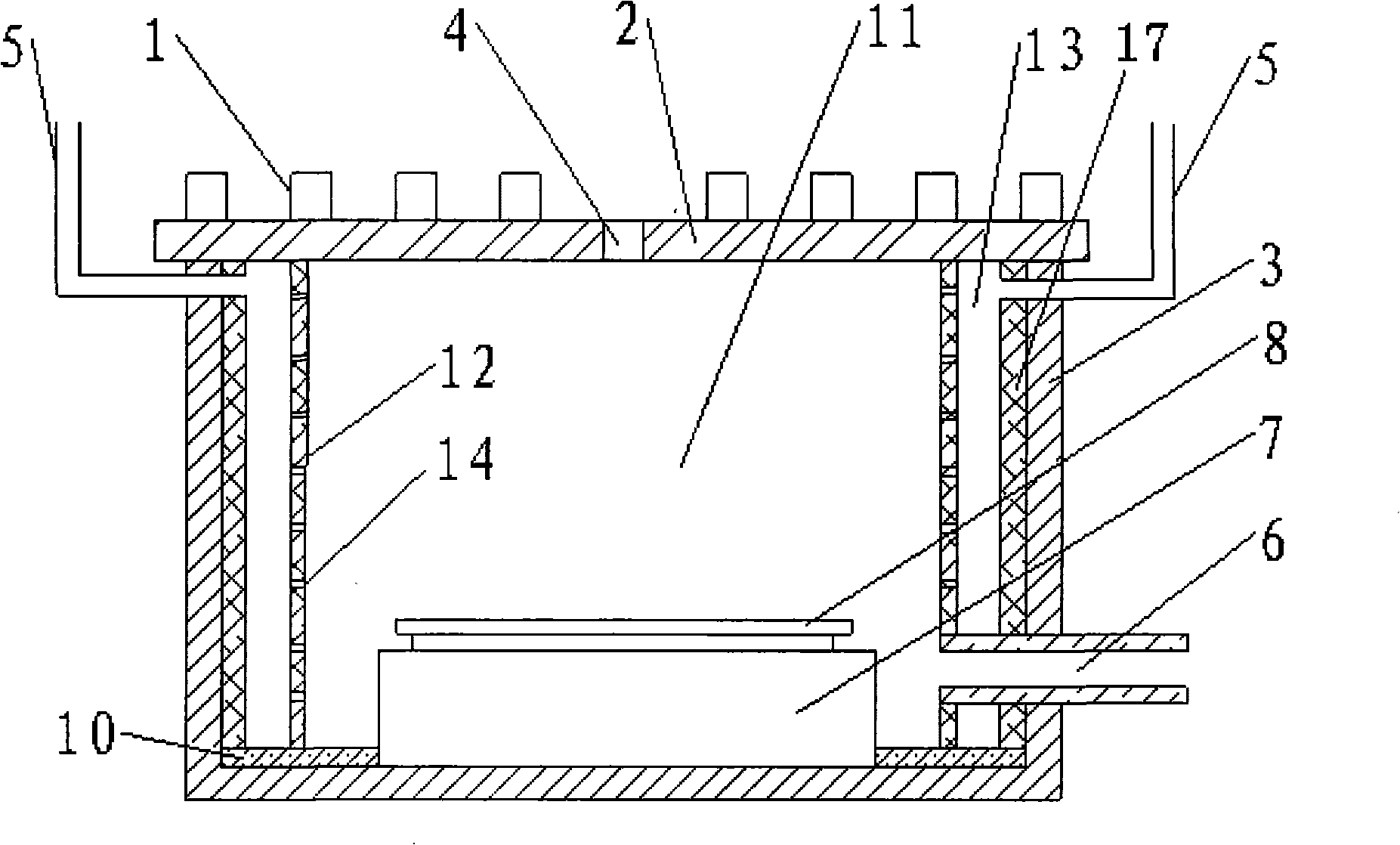

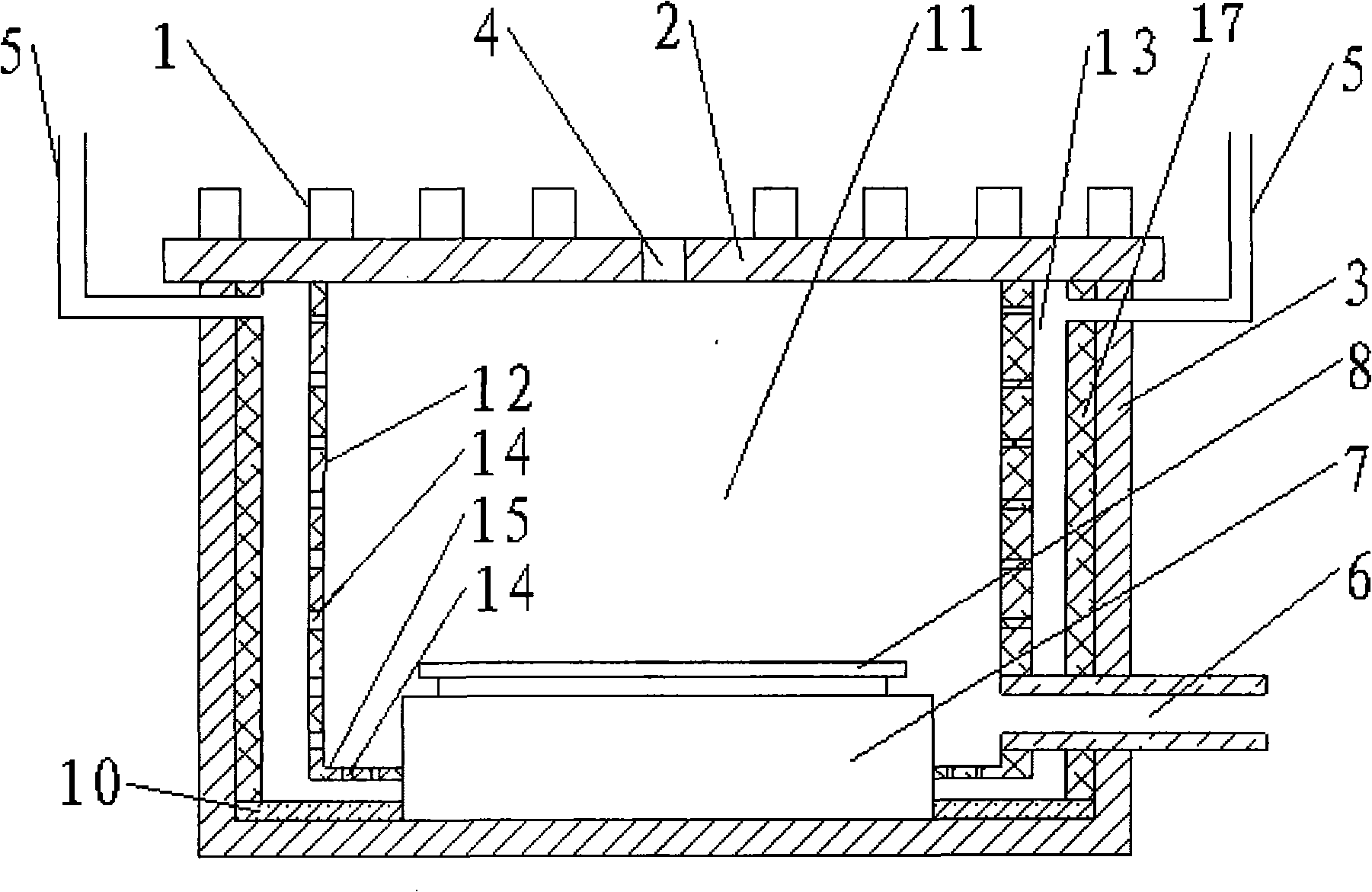

[0013] Chamber liner and chamber liner of the present invention, its preferred specific embodiment is as figure 2 As shown, the chamber lining includes an outer lining 17 and an inner lining 12, and there is a gap 13 between the outer lining 17 and the inner lining 12, and the inner lining 12 has a plurality of A through hole 14, an air inlet 5 is opened on the outer lining 17, and an exhaust outlet 6 is opened on the inner lining 12.

[0014] The edges of the through holes 14 may be chamfered or rounded to reduce resistance to airflow.

[0015] The diameter of the through hole is less than or equal to 6 mm, which can shield the plasma to a certain extent.

[0016] The inner lining of the chamber is arranged inside the reaction chamber. The reaction chamber includes a side wall 3 and a bottom wall. The air inlet 5 on the outer lining 17 communicates with the outside of the reaction chamber through the side wall 3. The inner lining The exhaust port 6 on 12 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com