Alkaline biomass particles for incinerating organic waste liquid and special equipment

A technology of biomass particles and organic waste liquid, applied in the direction of biofuel, waste fuel, solid fuel, etc., to protect the side wall of the incineration chamber, avoid potential safety hazards, and avoid incomplete combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

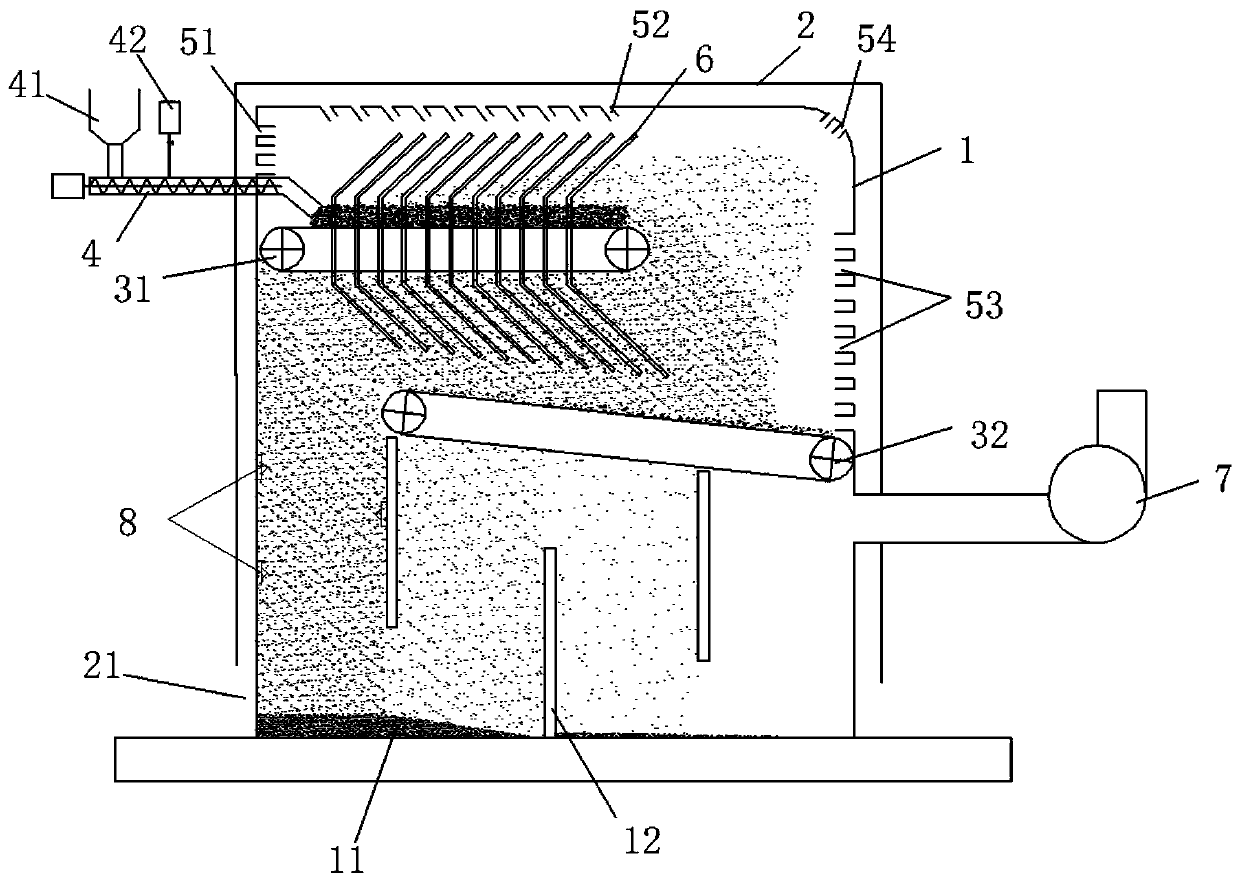

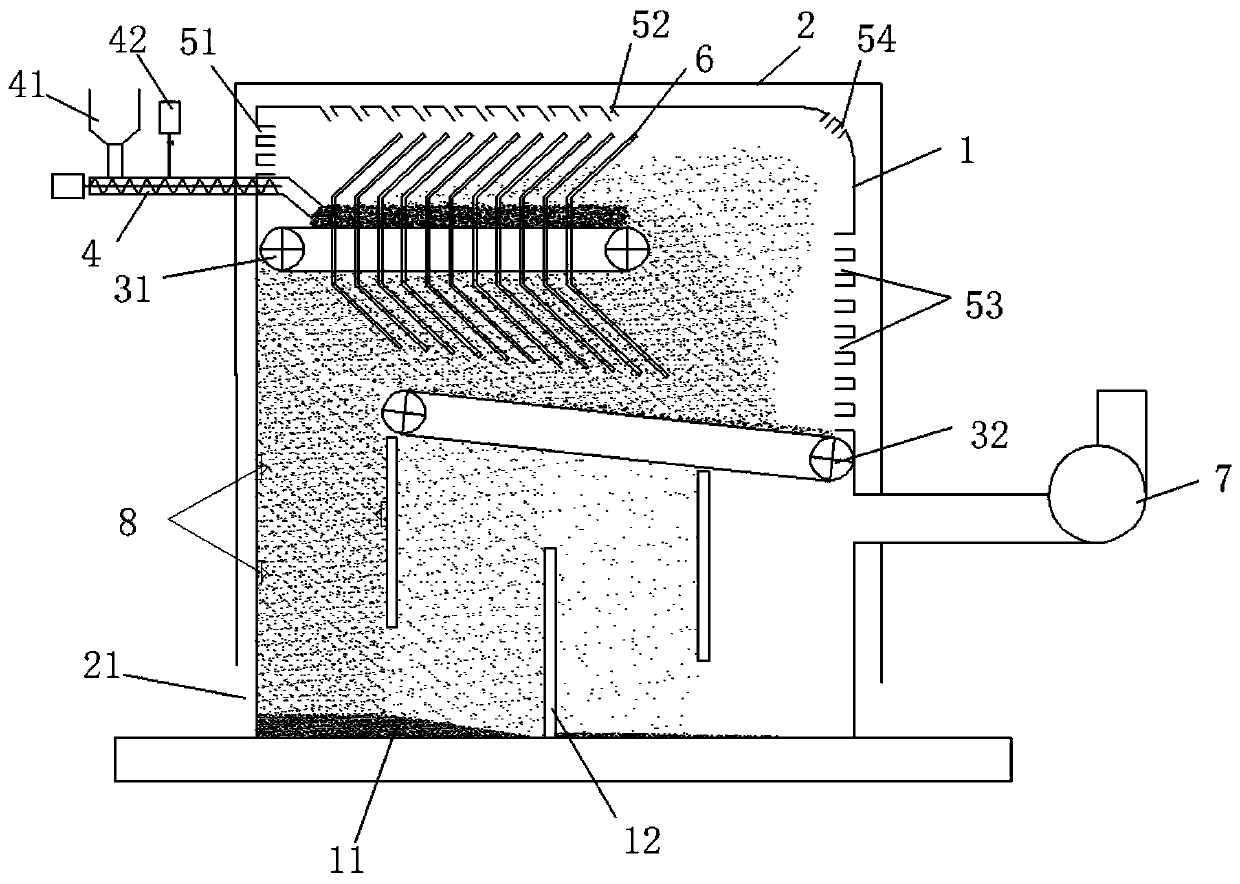

Method used

Image

Examples

Embodiment 1

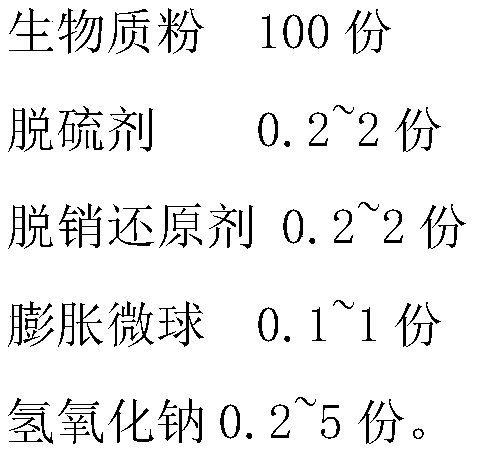

[0021] An alkaline biomass granule used to incinerate organic waste liquid. The organic waste liquid is sprayed on the biomass granule and then incinerated. The components include the following components:

[0022]

[0023] 0.2 parts of sodium hydroxide, the sodium hydroxide is mixed with raw materials in the form of aqueous solution sprayed on the biomass powder, and then extruded and granulated.

[0024] Calcium carbonate is selected as the desulfurizer, urea is selected as the out-of-stock reducing agent, and Akzo DU958 is selected as the grade of expansion microspheres.

[0025] Biomass powder is selected from domestic garbage biomass waste such as kitchen waste powder, industrial biomass waste such as sawdust, or agricultural biomass waste such as discarded mushroom sticks.

[0026] During the granulation process of biomass particles, the general temperature is 80-100°C, and the selection of expanded microspheres with an initial foaming temperature above 120°C can effe...

Embodiment 2

[0028] An alkaline biomass granule used to incinerate organic waste liquid. The organic waste liquid is sprayed on the biomass granule and then incinerated. The components include the following components:

[0029]

[0030] 5 parts of sodium hydroxide, sodium hydroxide is sprayed on the biomass powder in the form of aqueous solution and mixed with raw materials, and then extruded and granulated.

[0031] Calcium oxide is selected as the desulfurizing agent, ammonium sulfate is selected as the out-of-stock reducing agent, and Akzo DU120, which has an initial foaming temperature above 120° C., is selected as the expanded microsphere.

[0032] Biomass powder is selected from domestic garbage biomass waste such as kitchen waste powder, industrial biomass waste such as sawdust, or agricultural biomass waste such as discarded mushroom sticks.

Embodiment 3

[0034] An alkaline biomass granule used to incinerate organic waste liquid. The organic waste liquid is sprayed on the biomass granule and then incinerated. The components include the following components:

[0035]

[0036]

[0037] 0.5 parts of sodium hydroxide, the sodium hydroxide is sprayed on the biomass powder in the form of aqueous solution and mixed with raw materials, and then extruded and granulated.

[0038] The desulfurizer is selected from one or more of calcium hydroxide, the out-of-stock reducing agent is selected from a mixture of urea and ammonium sulfate, and the expanded microspheres are selected from Aksu DU40 or Aksu DU80 with an initial foaming temperature above 120°C.

[0039] Biomass powder is selected from domestic garbage biomass waste such as kitchen waste powder, industrial biomass waste such as sawdust, or agricultural biomass waste such as discarded mushroom sticks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com