Storage equipment for storing large oil drums

An oil barrel and storage technology is applied in the field of storage equipment for placing large oil barrels, which can solve the problems of surface scratches, labor-intensive manual draining of oil barrels, and easy rolling of oil barrels everywhere, so as to reduce labor intensity and protect side walls. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

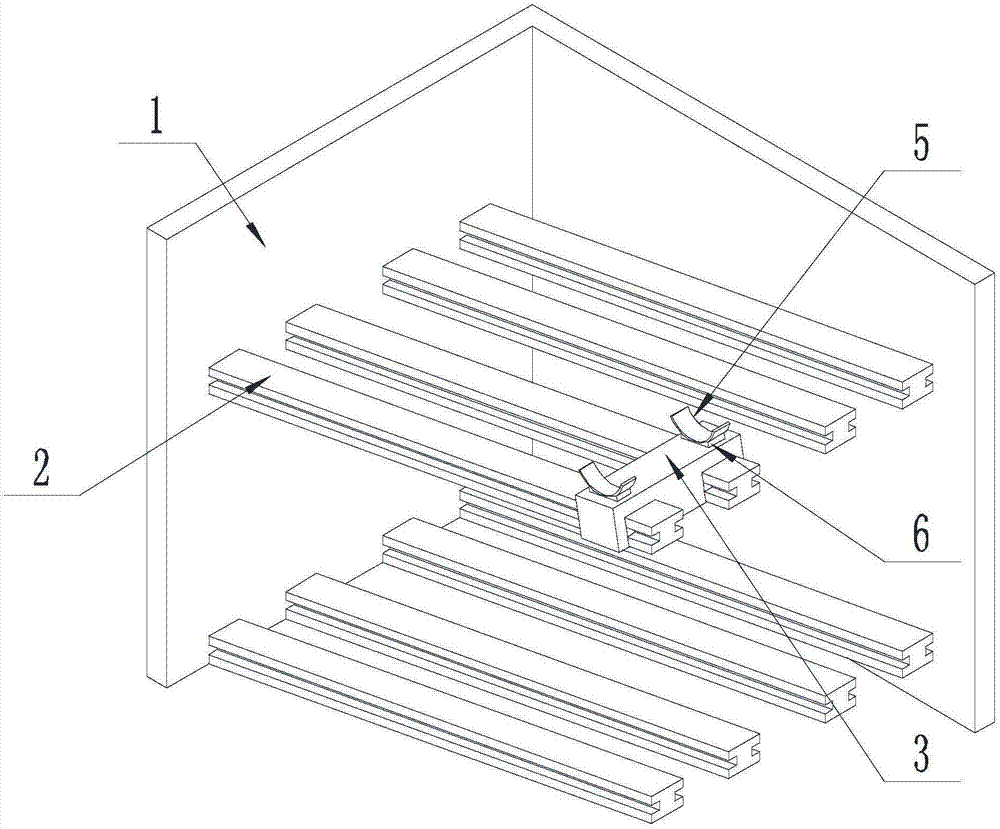

[0025] Such as Figure 1-Figure 2 As shown, the storage equipment for placing large oil drums in the present invention includes a warehouse body, a guide rod 2 and a moving block 3. The warehouse body is mainly composed of a wall 1, a ceiling and a door, and one end of the guide rod 2 is connected to the wall 1. Connected, the other end of the guide rod 2 extends in a direction away from the wall 1, and the horizontal position of the extended end is higher than the horizontal position of the end of the guide rod 2 connected with the wall 1;

[0026] A matching groove 4 is provided on the lower surface of the moving block 3. The matching groove 4 is matched with the guide rod 2, and the cross section of the matching groove 4 is non-circular. The moving block 3 is sleeved on the guide rod 2 through the matching groove 4 ; A mounting seat 5 is provided on the upper surface of the moving block 3.

[0027] Place the oil drum horizontally on the mounting seat 5 and make the axis of the ...

Embodiment 2

[0029] The present invention is based on Embodiment 1, and further illustrates the present invention.

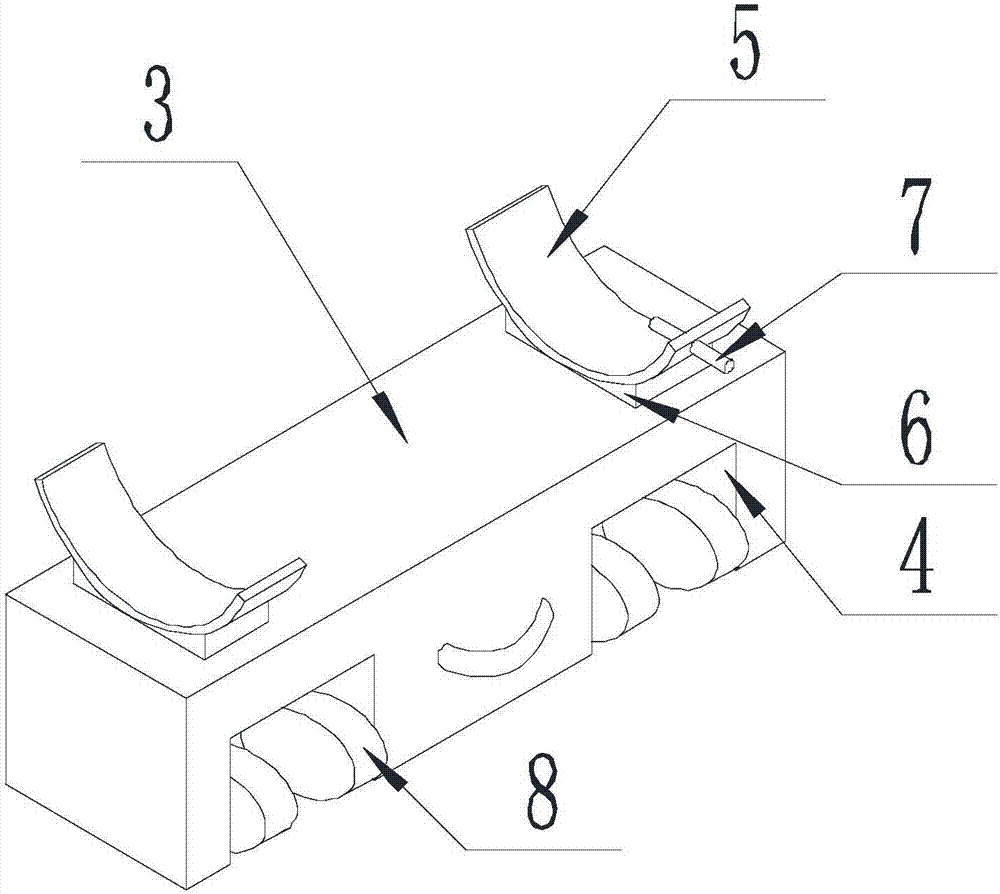

[0030] Such as Figure 1-Figure 2 As shown, in the storage equipment of the present invention for placing large oil drums, the mounting base 5 is an arc plate, the convex surface of which is connected with the upper surface of the moving block 3, and the axis of the mounting base 5 is perpendicular to the axis of the fitting groove 4 and parallel to Move the upper surface of block 3.

[0031] Further, a cushion block 6 is provided between the convex surface of the mounting base 5 and the upper surface of the moving block 3. The end of the cushion block 6 close to the mounting base 5 is in seamless contact with the convex surface of the mounting base 5. The end of the upper part 6 close to the moving block 3 is in seamless contact with the upper surface of the moving block 3.

[0032] Furthermore, it further includes a bolt 7 which is threadedly connected with the mounting base 5,...

Embodiment 3

[0036] The present invention is based on Embodiment 1, and further illustrates the present invention.

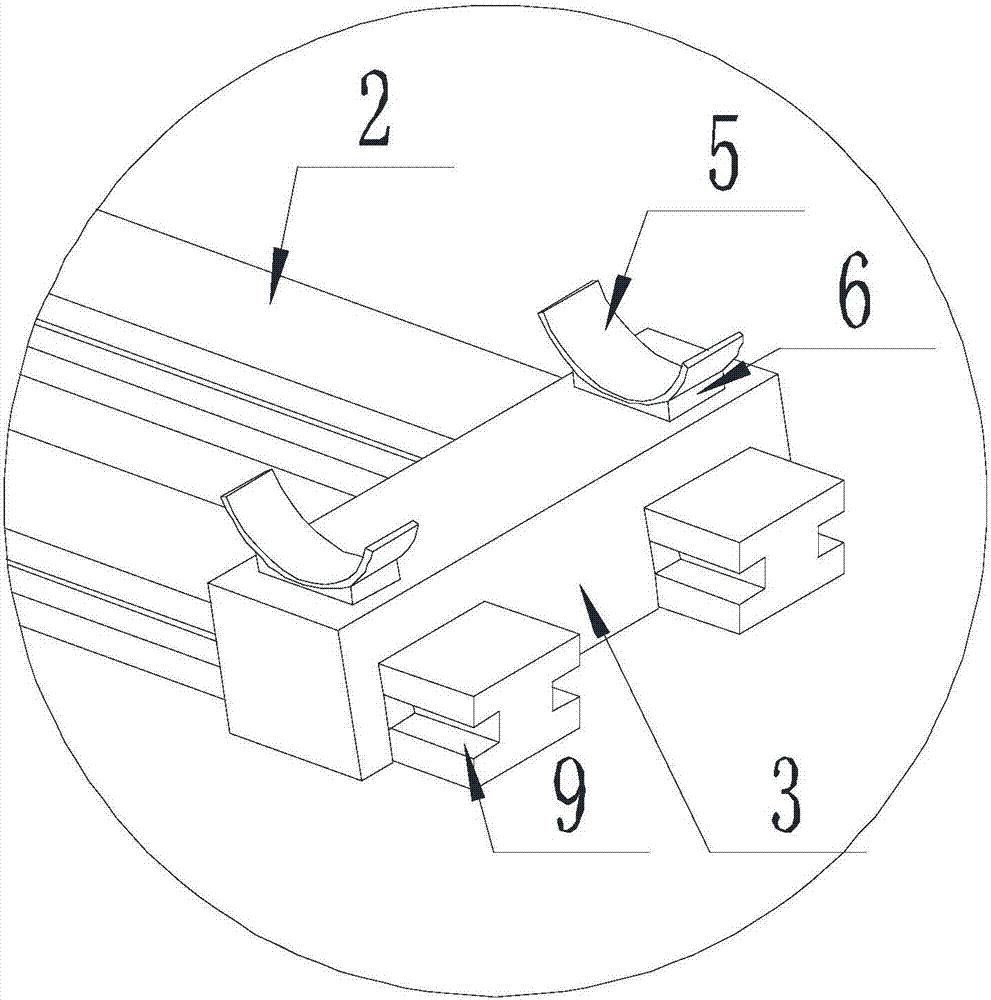

[0037] Such as Figure 1-Figure 2 As shown, in the storage equipment for storing large oil drums according to the present invention, a sliding groove 9 is provided on the side of the guide rod 2, and the axis of the sliding groove 9 is parallel to the axis of the guide rod 2. A roller 8 is provided on the wall of the matching groove 4, and the roller 8 is located in the sliding groove 9. Changing the sliding of the moving block 3 on the guide rod 2 into rolling can avoid the situation that the moving block 3 cannot move due to excessive friction.

[0038] Further, there are two matching grooves 4 on the lower surface of the moving block 3, and the matching grooves 4 are respectively matched with a guide rod 2 respectively. Moreover, a support column can be arranged around the guide rod 2 to support the guide rod 2 according to needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com