Disc brake and brake pad for a disc brake, especially for a utility vehicle

A technology of disc brakes and brake linings, applied in the direction of brake components, brake types, axial brakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

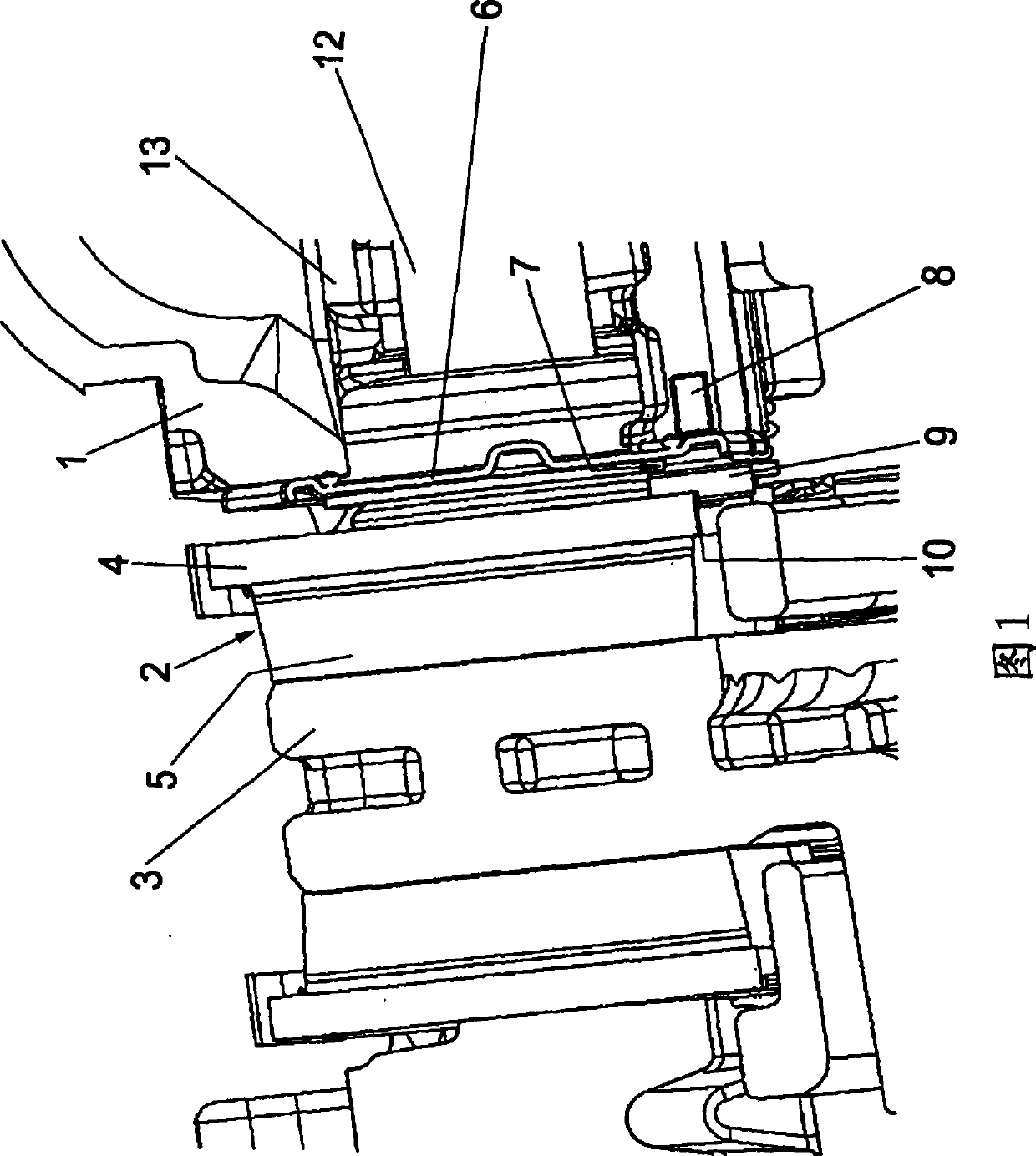

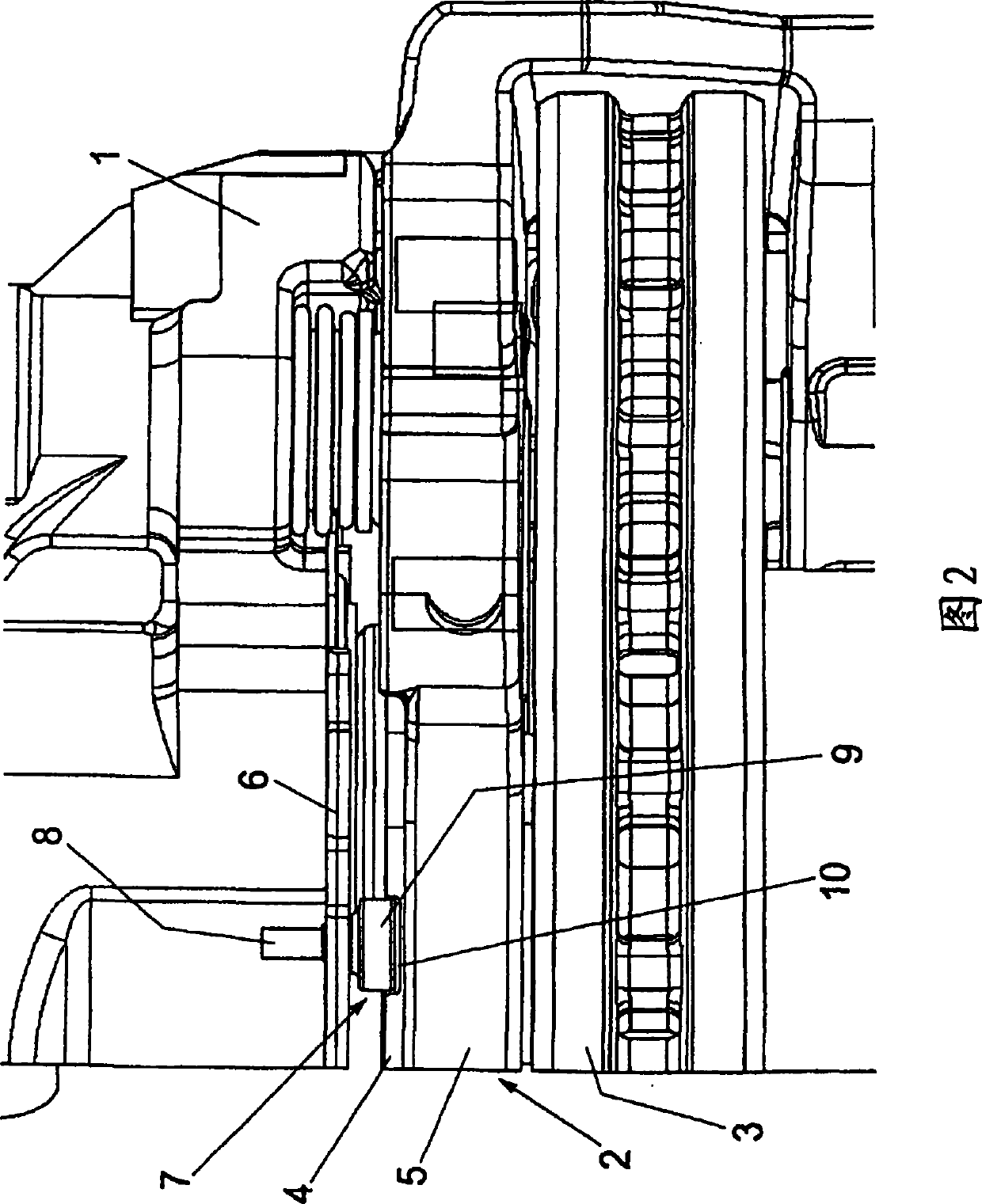

[0022] 1 and 2 show a disc brake, in particular for commercial vehicles, with a brake caliper 1 which overlaps a brake disc 3 and which is supported on both sides by a lining carrier plate 4 and a friction brake caliper. A brake lining 2 formed by a lining 5 can be operatively connected to the brake disk, wherein the friction lining 5 is pressed against the brake disk 3 during braking.

[0023] Arranged in the assembly chamber 13 is an adjusting shaft 12 which, on the one hand, is connected to a pressure device (not shown) and, on the other hand, bears against the lining carrier plate 4 .

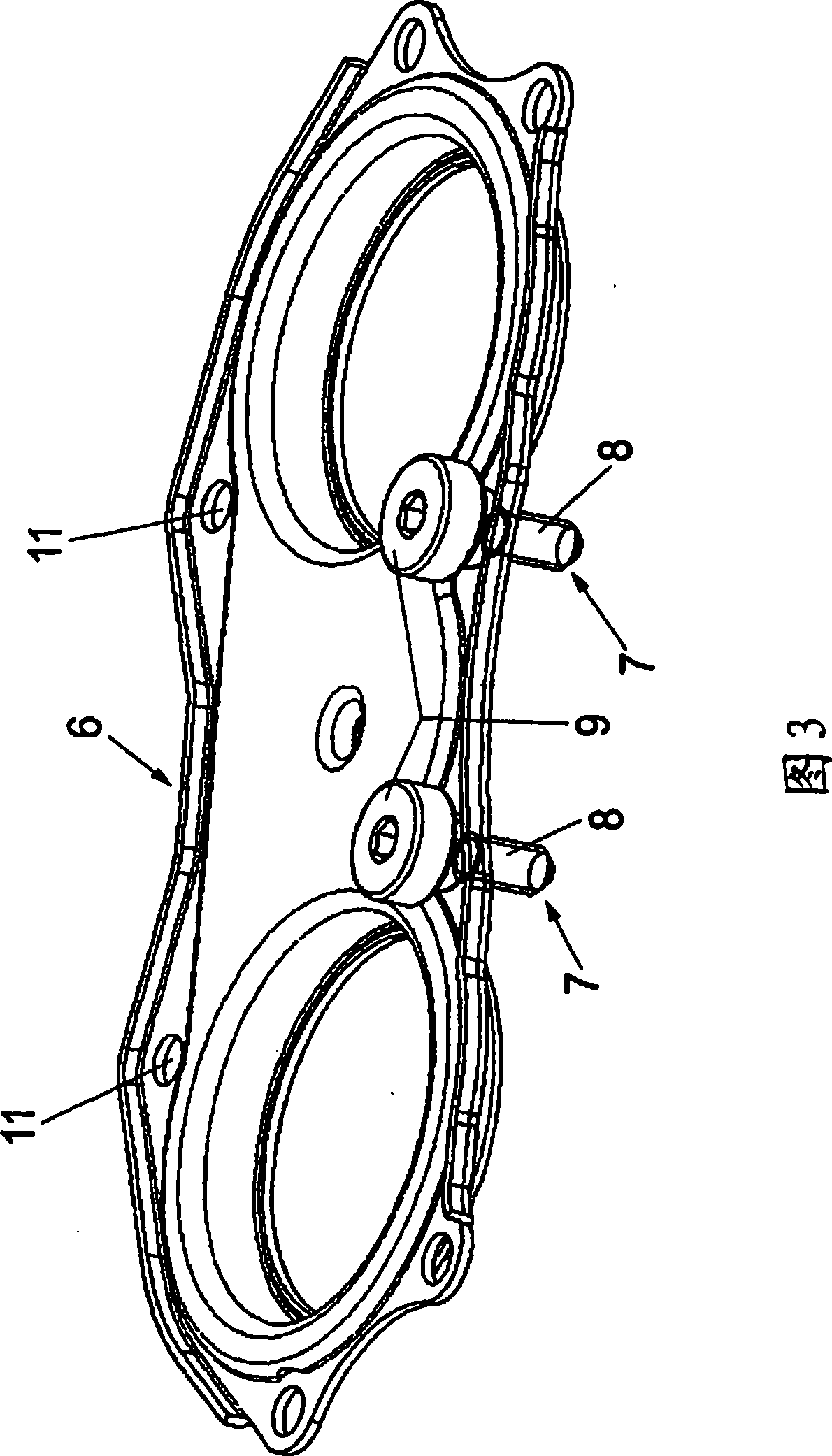

[0024] The assembly chamber 13 is closed in the direction of the brake disc 3 by a closure cover 6 , and by means of screws 7 which are screwed peripherally into threaded holes of the brake caliper 1 , wherein the screws 7 are guided through the closure cover 6 The hole 11 (Figure 3).

[0025] At least some of the screws 7 (two screws 7 in the present embodiment) are designed such that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com