Aldehyde capture agent and construction material using the same

A technology for building materials and scavengers, applied in construction, building components, building structures, etc., can solve the problems of difficulty in showing the same performance, difficulty in finding organic materials, and rising material prices, and achieves good storage stability and viscosity. Small, not easy to gel and cloudy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

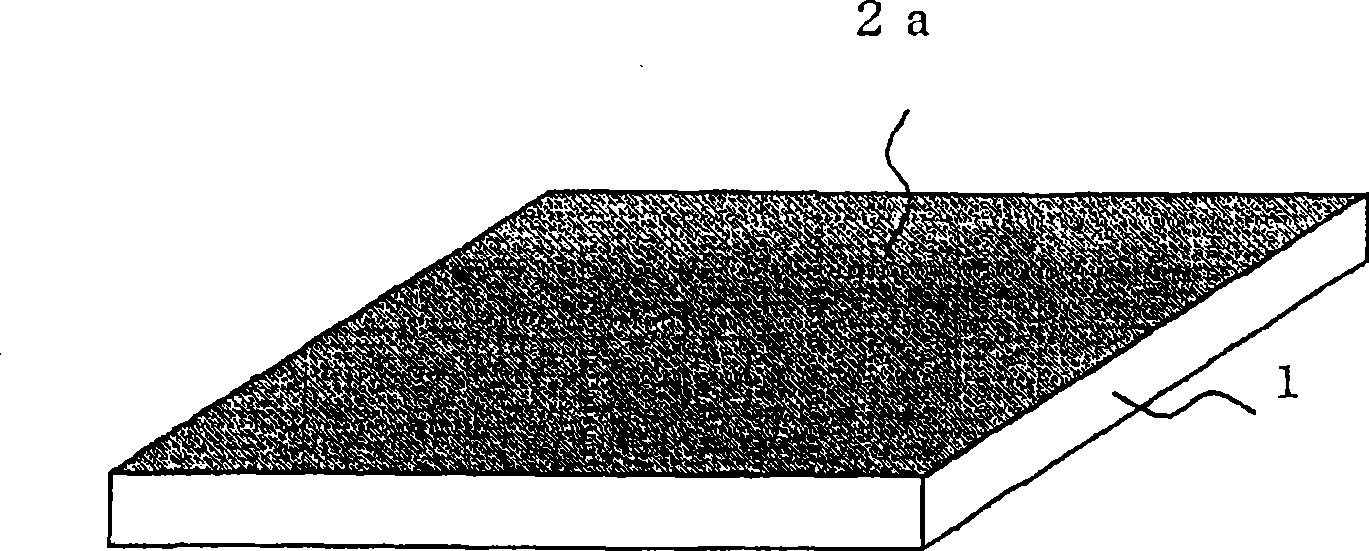

Embodiment 8

[0105] Glass wool is used as the inorganic fiber. The following adhesive is used as the adhesive, and the adhesive is 100 parts by mass of a mixture of 70:30 mixture of resole phenolic resin and urea resin, adding 0.2 mass part of aminosilane (aminosilane) and 1 mass part Obtained from ammonium sulfate which becomes a curing catalyst. Adhesive is given to glass wool so that the amount of adhesive attached is 9.5% by mass based on the mass of the inorganic fiber heat-insulating and sound-absorbing material to obtain a thickness of 25 mm and a density of 96 kg / m. 3 Inorganic fiber insulation and sound-absorbing materials.

[0106] The aldehyde scavenger of Example 1 was applied by the spraying method so that the adhesion amount thereof was 4.8 g / m in terms of solid components relative to the surface area of the inorganic fiber heat-insulating and sound-absorbing material obtained by the above-mentioned method. 3 , Obtain the building material of embodiment 8.

Embodiment 9~12

[0108] In Example 8, except having used the aldehyde scavenger of Examples 2-5 instead of the aldehyde scavenger of Example 1, it carried out similarly to Example 8, and obtained the building material of Examples 9-12.

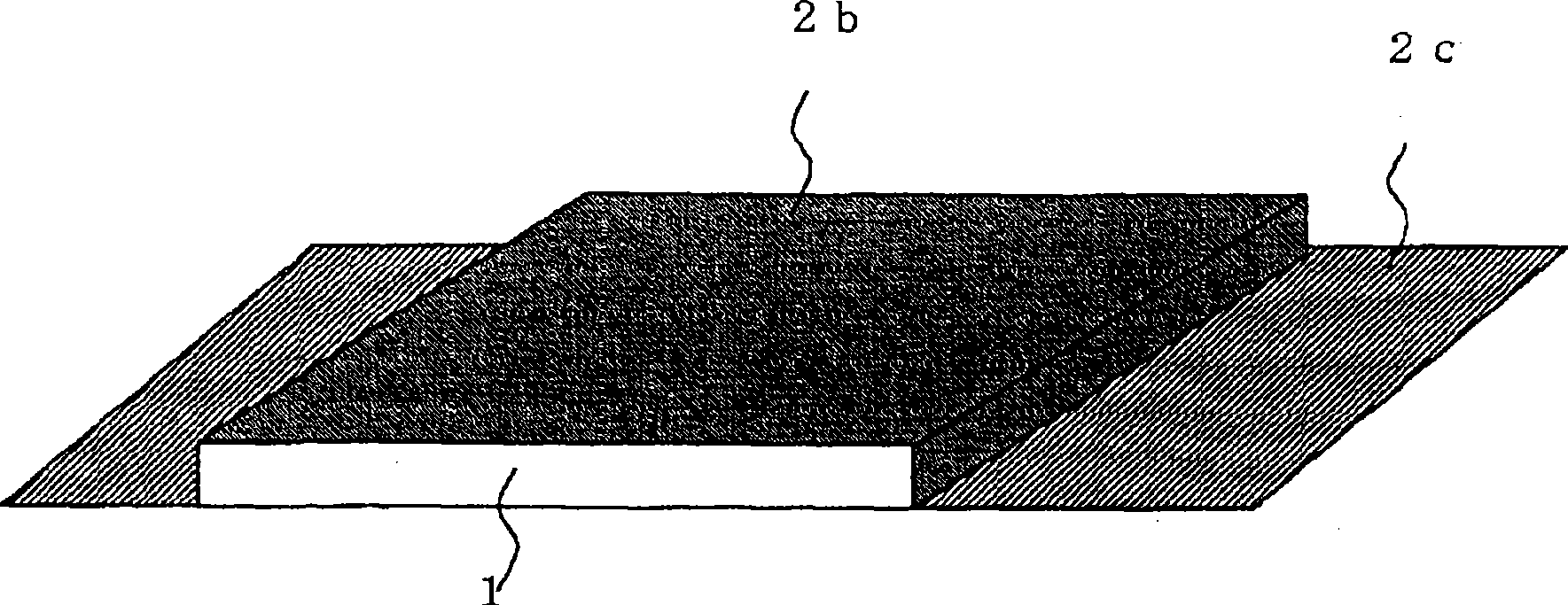

Embodiment 13

[0128] Glass wool is used as the inorganic fiber. The following adhesive is used as the adhesive, and the adhesive is 100 parts by mass of a mixture of 70:30 mixture of resole phenolic resin and urea resin, adding 0.2 mass part of aminosilane (aminosilane) and 1 mass part Obtained from ammonium sulfate which becomes a curing catalyst. Adhesive is given to glass wool so that the amount of adhesive attached is 9.5% by mass based on the mass of the inorganic fiber heat-insulating and sound-absorbing material to obtain a thickness of 50mm and a density of 32kg / m 3 Inorganic fiber insulation and sound-absorbing materials.

[0129] The aldehyde scavenger of Example 1 was applied by spraying so that the amount of adhesion relative to the surface area of the obtained inorganic fiber heat-insulating and sound-absorbing material was 4.8 g / m in terms of solid components 3 , followed by 30g / m in terms of solid components 2 The amount of the chloropropylene rubber (chrolopropylene rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com