Fan impeller

A fan wheel and hub technology, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc. Increase the difficulty of manufacturing and other issues to avoid uneven weight, improve balance accuracy, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

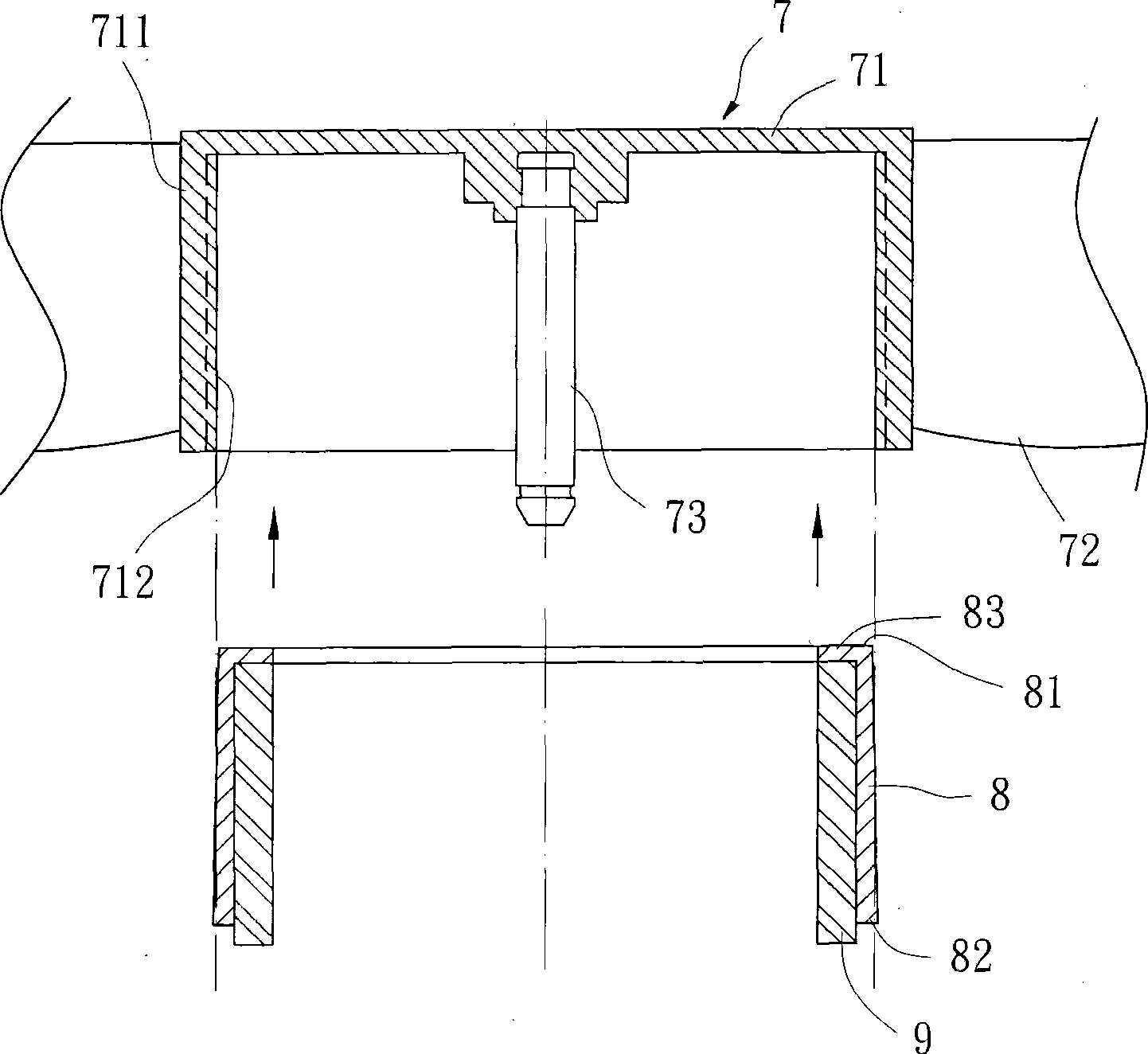

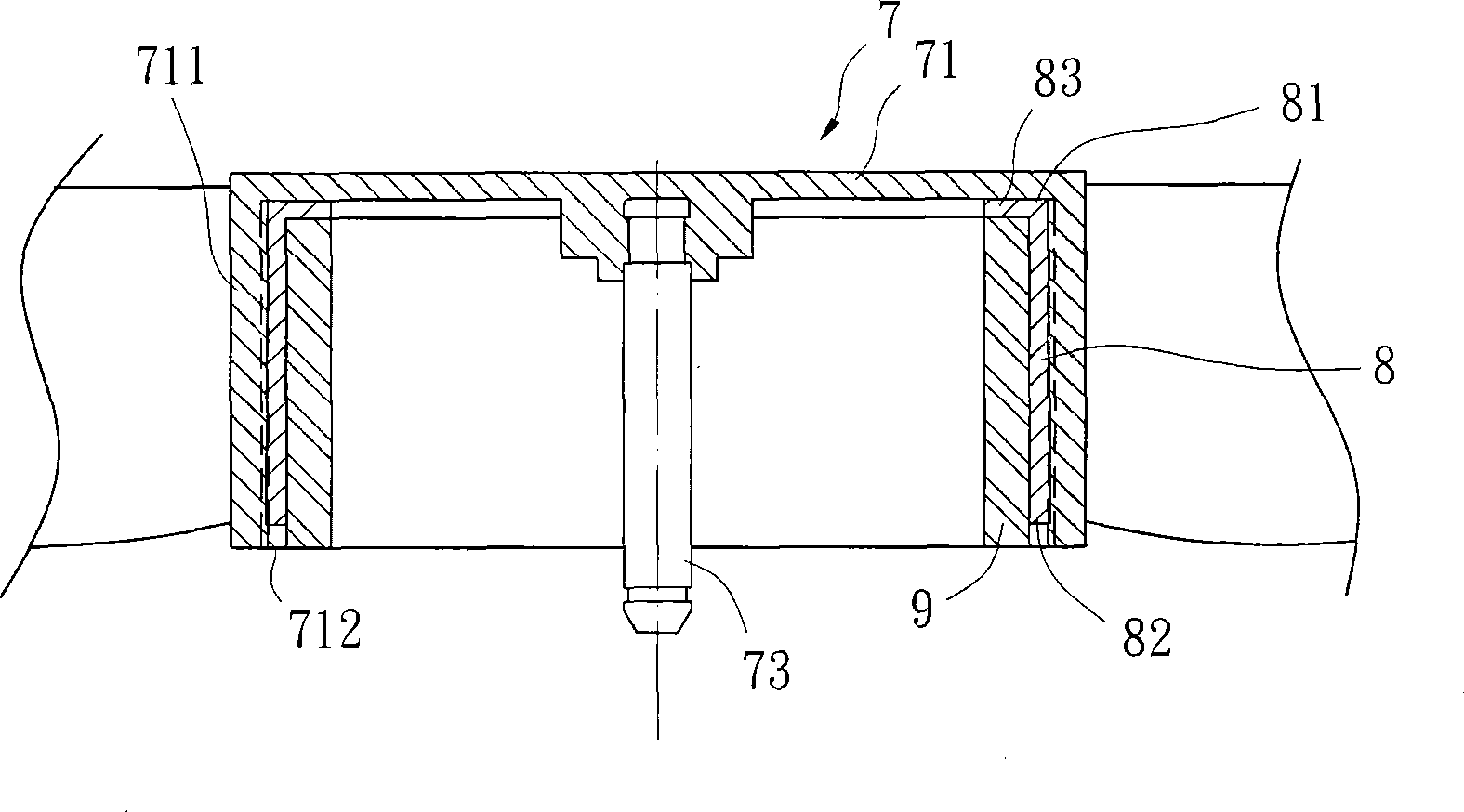

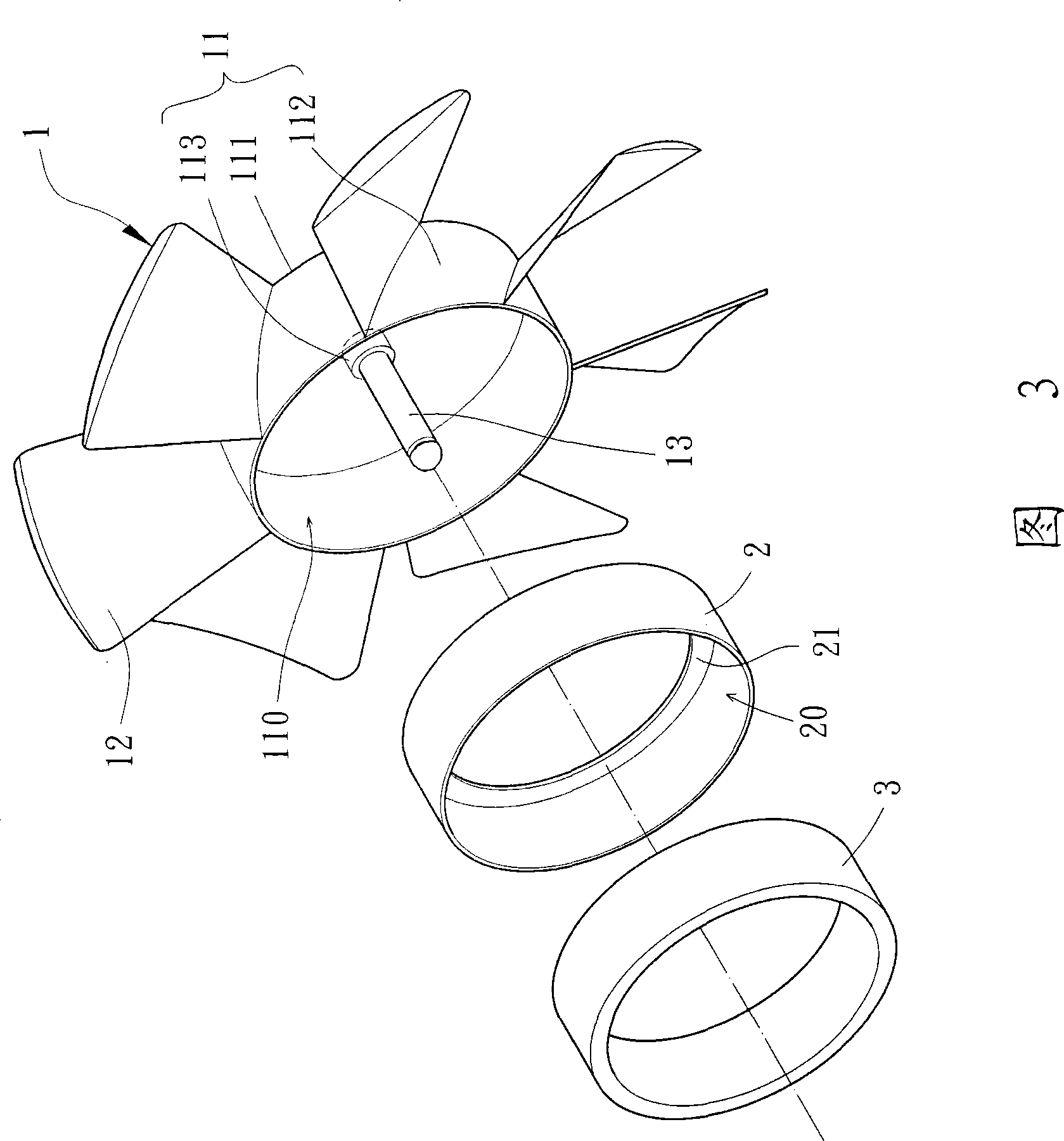

[0016] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, as follows:

[0017] Please refer to FIG. 3, the first embodiment of the present invention: the fan wheel 1 is made of a plastic material (such as polyphenylene sulfide, polypropylene, resin, polyetheretherketone, etc.) by injection molding, and It can be selected as an axial-flow fan wheel or a blower-type fan wheel. The fan wheel 1 of this embodiment is an axial-flow fan wheel as an example of implementation. The fan wheel 1 has a hub 11, several fan blades 12 and a shaft 13, the hub 11 is in the shape of a hollow cylinder; the fan blades 12 are connected to the outer peripheral surface of the hub 11 in an equidistant arrangement; The shaft 13 is coupled to the center of the hub 11 .

[0018] 3 and 4, the hub 11 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com