Combustion chamber structure of direct injection type diesel engine

A technology for combustion chambers and diesel engines, applied to combustion engines, mechanical equipment, engine components, etc., to achieve good fuel atomization and diffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

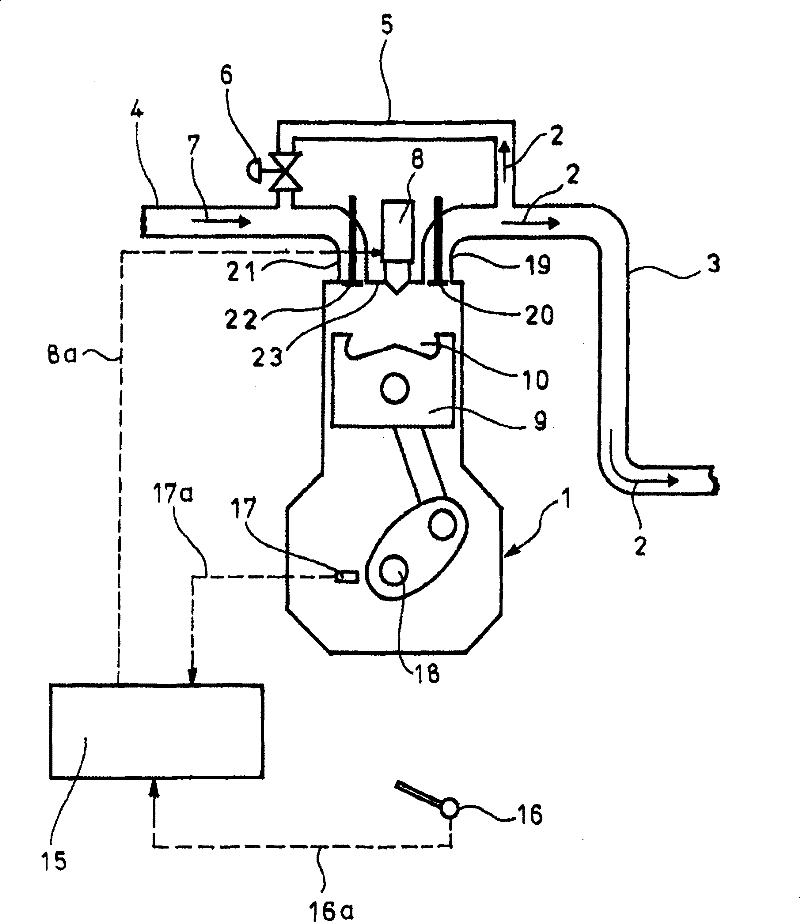

[0025] The embodiments of the present invention are explained below with reference to the drawings. Figure 13-27 Shows an embodiment of the present invention. versus figure 1 versus figure 2 The same reference numerals denote the same components.

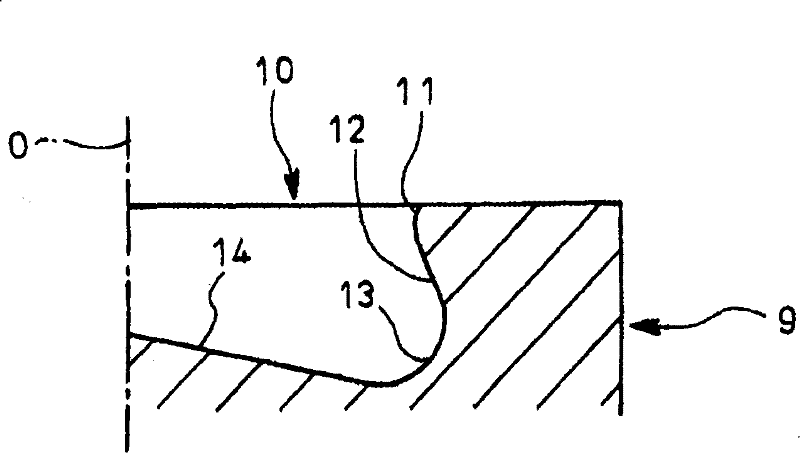

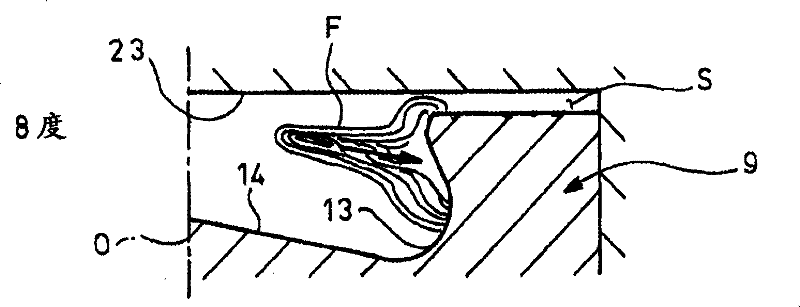

[0026] Regarding the above reference figure 1 The illustrated direct injection diesel engine 1, in this embodiment, is as Figure 13 As shown, the outer periphery of the opening of the recess 10 that is recessed on the top surface of the piston 9 is provided with a stepped cutout 24 that is recessed relative to the top surface of the piston 9. The outer peripheral portion of the bottom surface of the cutout portion 24 rises radially outward along a gentle curved surface to form the top surface of the piston 9, and an inlet lip 11 is formed at the next step of the top surface of the piston 9, and the inlet lip 11 is formed by The inner peripheral portion of the cutout portion 24 and the combustion chamber wall portion 12 rising from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com