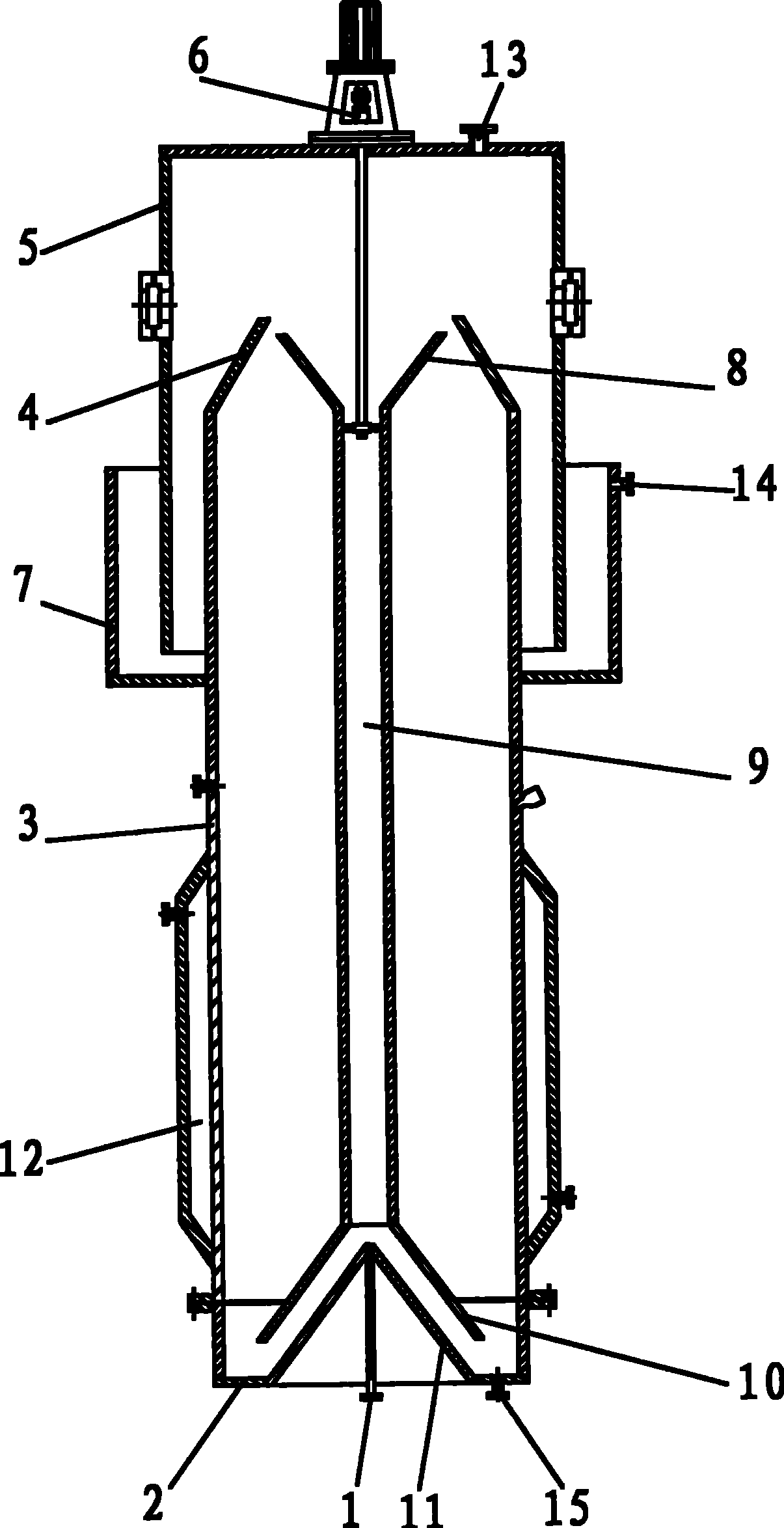

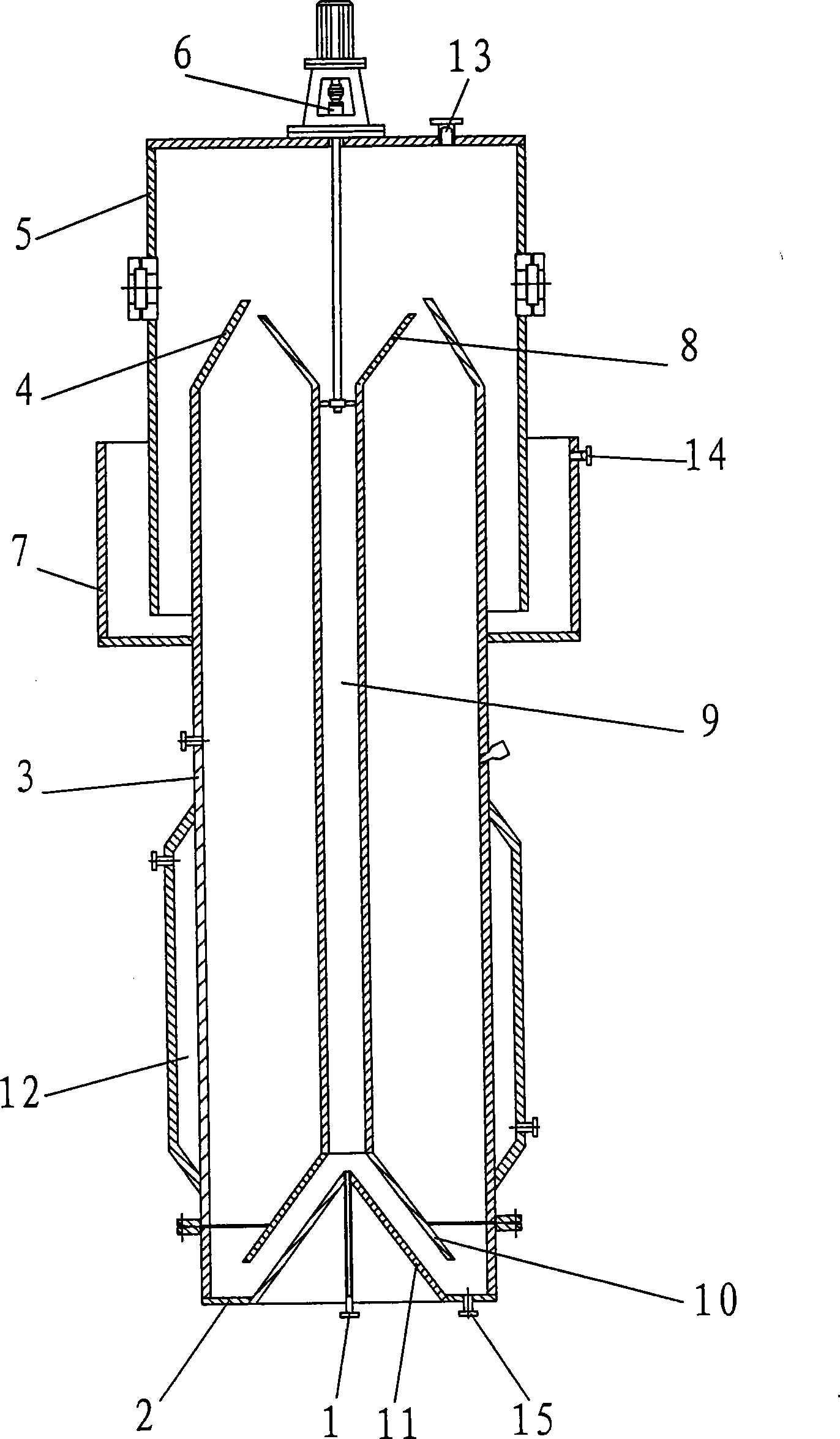

Vertical type anaerobic reactor

An anaerobic reactor and reactor technology, applied in the direction of anaerobic digestion treatment, etc., can solve the problems of secondary pollution, high energy consumption, low biogas yield, etc., to achieve reduced area, uniform distribution of material and liquid, and improved collection degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A vertical anaerobic reactor is composed of a feed inlet 1, a reactor bottom plate 2, a reactor cylinder 3, a gas collecting hood 5 and an overflow tank 7, and the reactor cylinder 3 is a vertical cylindrical cylinder. A cylindrical overflow tank 7 is welded or riveted on the outer wall of the reactor cylinder 3, and the outer wall of the overflow tank 7 is provided with a discharge port 14, and a cylindrical gas collecting hood 5 is arranged above the reactor cylinder 3 to collect The bottom end of the gas hood 5 is located at the gap between the reactor cylinder 3 and the overflow tank 7, and the upper end of the gas collecting hood 5 is a closed structure, on which a biogas outlet 13 is provided; at the bottom of the reactor cylinder 3 The reactor bottom plate 2 is welded, the bottom of the reactor bottom plate 2 is connected with a mud outlet 15, the top of the reactor bottom plate 2 is welded with a bottom plate conical flow guide 11, and the top of the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com