Large brush and comb transmission mechanism

A transmission mechanism and brush technology, which can be used in deburring devices, textiles and paper making, fiber processing, etc., can solve the problems of large brush pulleys, large brush gear boxes with complex structures, difficult replacement of large brush shafts, and easy falling off of cutting knives. , to achieve the effect of simple structure, low cost and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

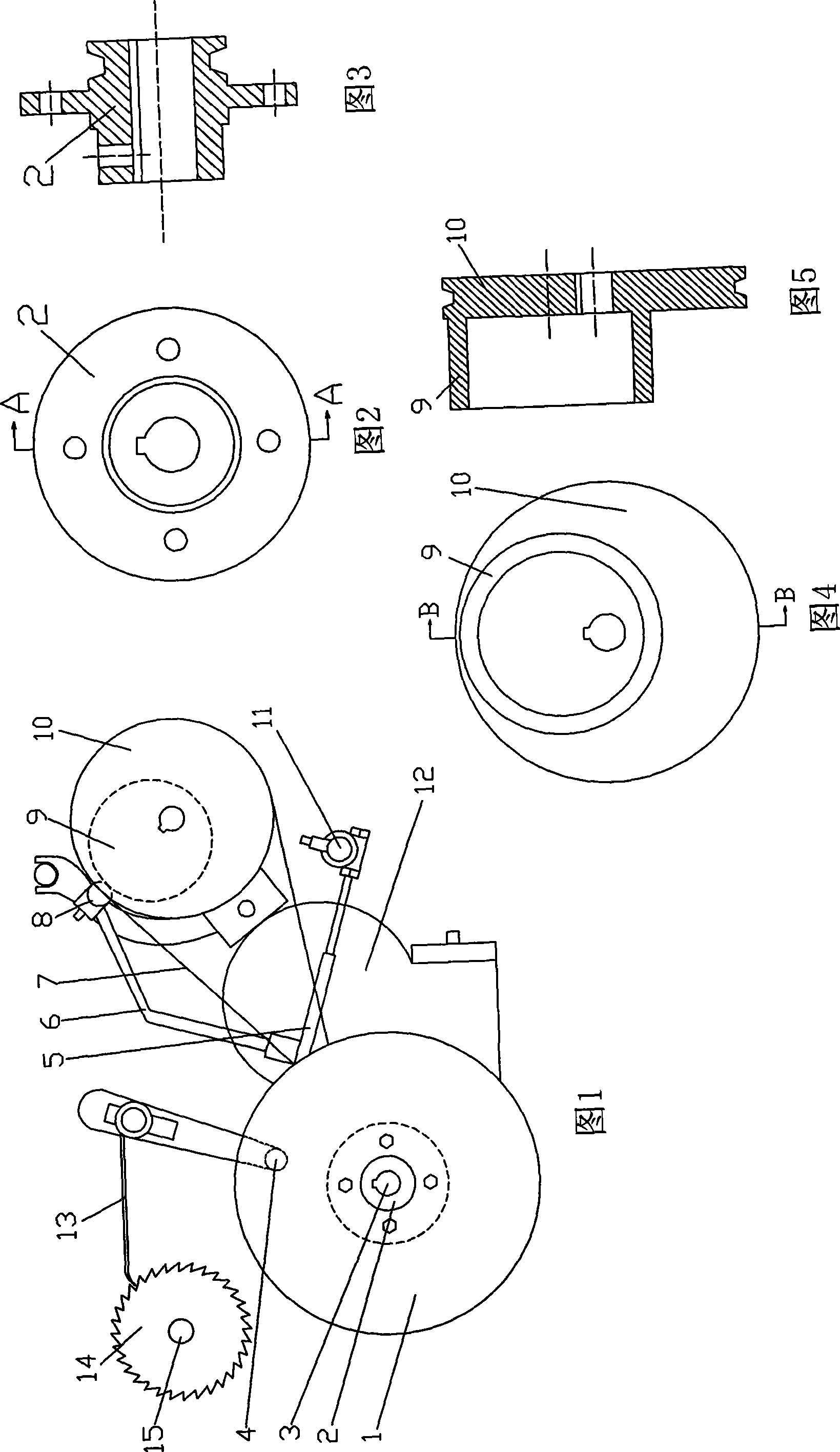

[0015] In the embodiment of FIG. 1 , four screw holes are respectively provided on the cover belt pulley (1) and the large brush driving pulley (2), and bolts are respectively passed through the holes to connect the cover belt pulley (1) and the large brush driving pulley (2). The large brush driving pulleys (2) are fastened together and installed on the shaft end of the transmission mandrel (3). The lower end of the support arm of the lever (13) is fixed on the shaft (4), and the cutting arm (5) One end is sleeved on the shaft (4), and the other end of the cutter arm (5) is provided with a cutter (11); the upper end of the lever support arm is provided with a long slot hole, and one end of the lever is installed in the long slot hole , the other end is in contact with the small brush ratchet (14), the small brush ratchet (14) is installed on the ratchet drive shaft (15); the support rod (6) is installed and fixed on the cutting arm (5), with an eccentric wheel The large brush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com