Control method for frequency conversion compressor unit for natural gas substation for automobile

A technology of compressor unit and gas filling sub-station, which is applied in pump control, liquid variable capacity machinery, vehicle maintenance, etc. It can solve the problems of low overall utilization rate of the unit and increase investment, and achieve uniform gas supply capacity and energy saving effect. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The principle and specific implementation of the present invention will be described below in conjunction with the accompanying drawings.

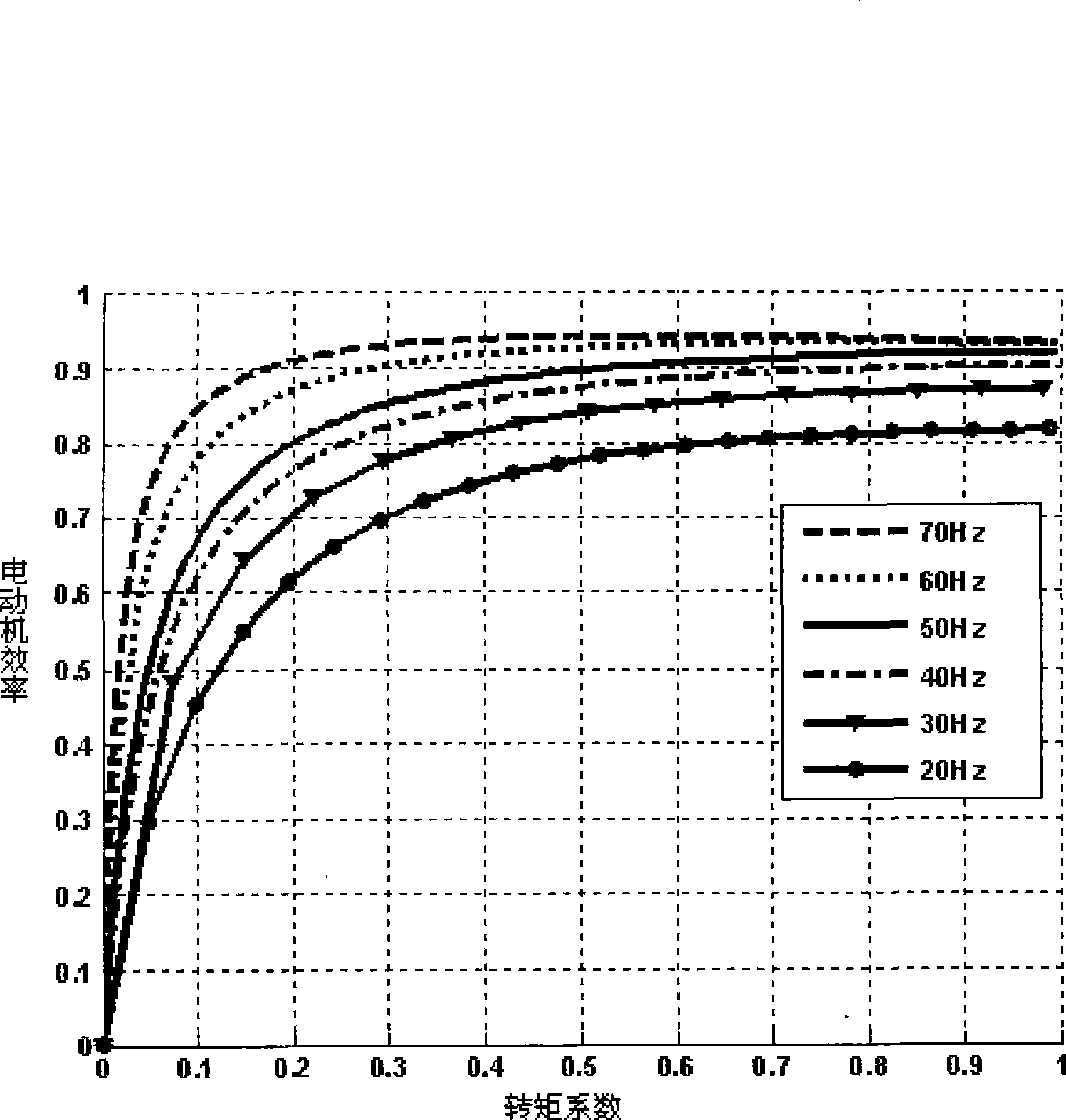

[0041] The principle of the present invention is: when the suction pressure and discharge pressure of the compressor are constant, the compressor can be regarded as a constant torque load. However, the efficiency of the motor will be different at different frequencies. Therefore, there is an optimal operating frequency corresponding to each determined operating point. When the operating point of the compressor changes, the required torque of the compressor will also change, and the optimal operating frequency will also change accordingly.

[0042] The calculation shows that under the same torque, the higher the frequency, the higher the efficiency of the motor, such as figure 1 shown. For example, when the load torque is more than 90% of the rated torque, the efficiency is 93% when running at 60Hz, 92% when running at power freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com