Metal-rubber ring combination support high-speed rotating system for magnetic suspension bearing

A technology of magnetic suspension bearing and metal rubber, which is applied in the field of magnetic suspension, can solve the problems of not being able to greatly improve the system support damping and not having many practical applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

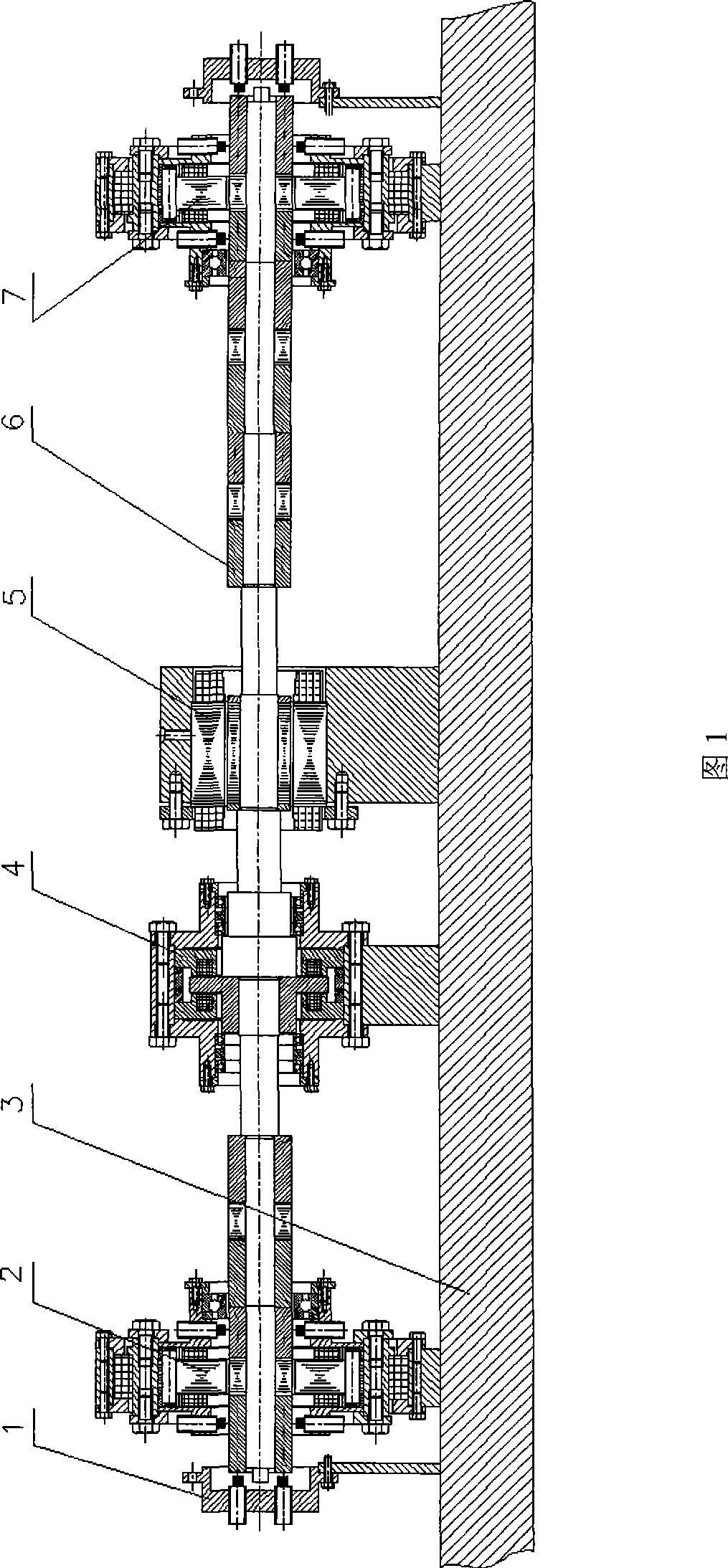

[0018] As shown in Figure 1, the device of the present invention includes an axial sensor assembly 1 (both ends), a radial magnetic bearing and a metal rubber ring combined support assembly 2, 7, a base 3, an axial magnetic bearing assembly 4, and a high-frequency motor assembly 5. Rotor assembly 6.

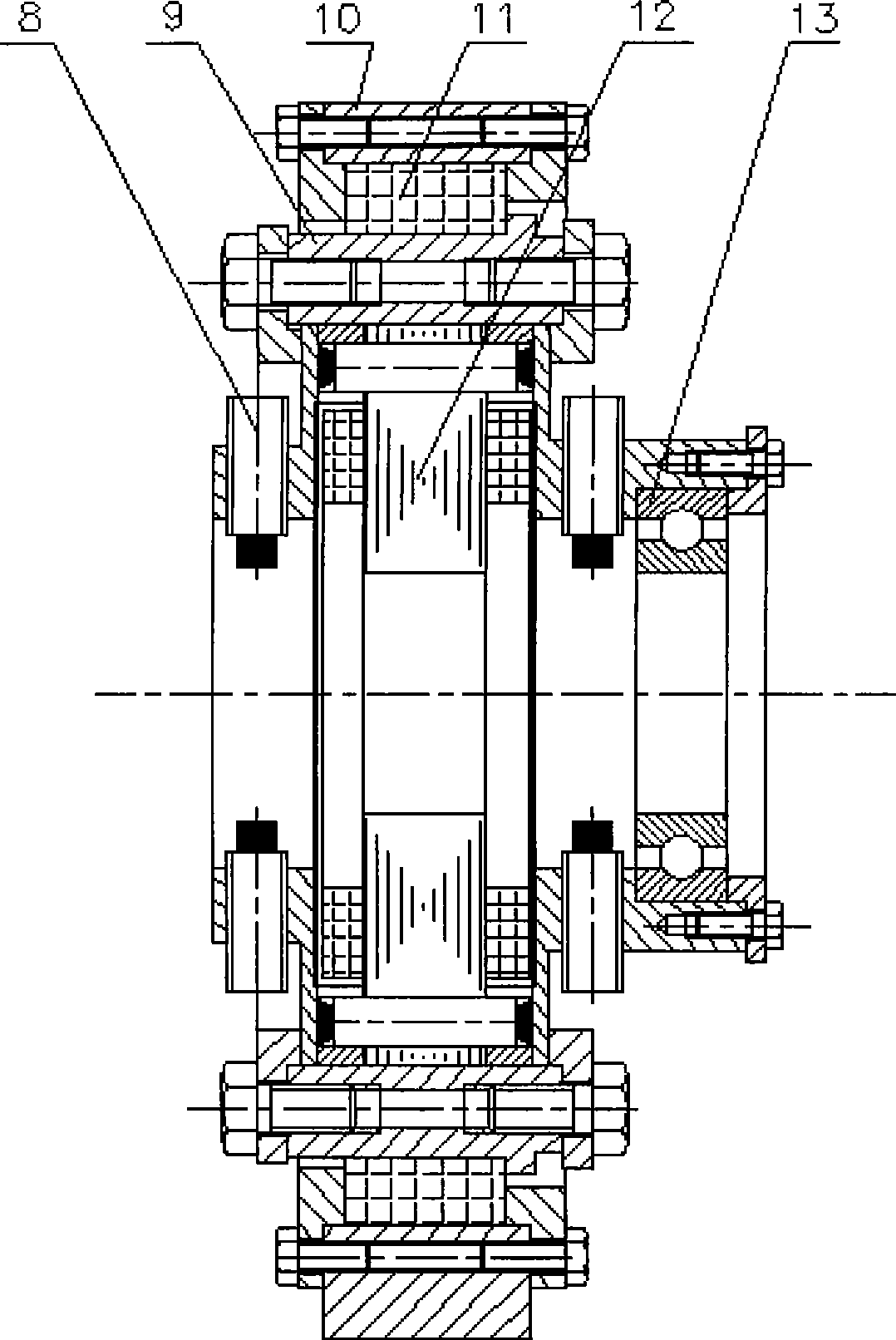

[0019] The device of the invention improves the structure of the radial magnetic suspension bearing on the basis of the general magnetic suspension bearing rotor system, and surrounds a layer of suitable metal rubber rings outside the radial magnetic suspension bearing. In order to ensure reliable contact, the magnetic suspension bearing and the metal rubber ring can be placed in the same housing cavity, the specific structure is as follows figure 2 .

[0020] The structural parameters of the radial magnetic suspension bearing are shown in Table 1:

[0021] Table 1 Structural parameters of radial magnetic suspension bearing

[0022]

[0023] The structural parameters of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com