Station boiler air preheater hot spot detecting method based on analog computation of rotor temperature field

A technology of analog calculation and rotor temperature, applied in the application of thermometers, thermometers, instruments, etc., it can solve the problems of large limitations, the measurement accuracy cannot meet the requirements, and the temperature field distribution of the air preheater cannot be accurately obtained, and achieves safety and stability. The effect of improved operation, reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

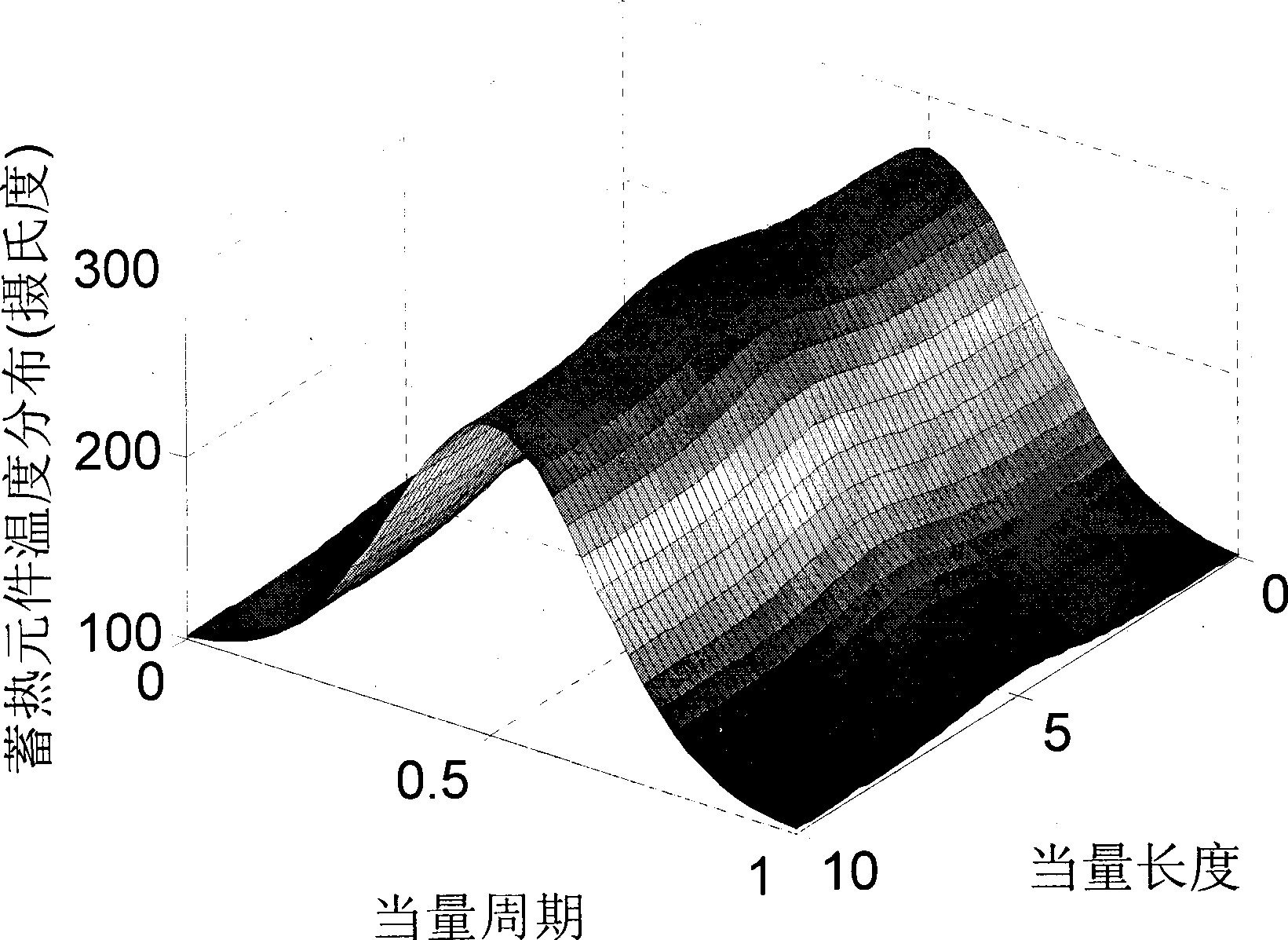

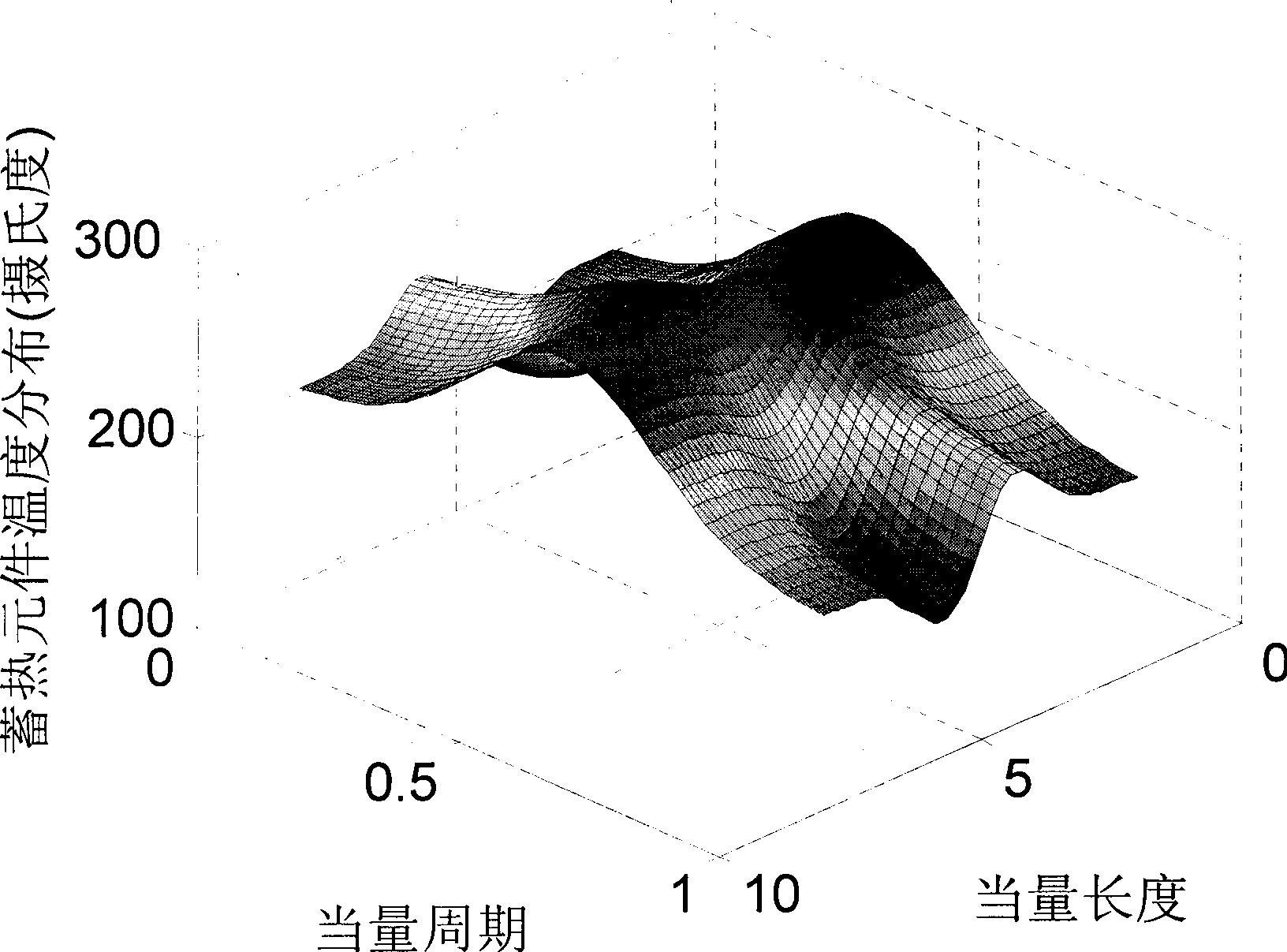

[0085] Table 1 shows the structural parameters of the three-compartment rotary air preheater of a 600MW thermal power generating unit. In the calculation, the cold and heat cycles and the preheating length of the heat storage element are respectively divided into 50 units. According to the ratio of the primary and secondary air on the air side of the air preheater of the 600MW unit, the first 14 units of the cold cycle are regarded as the primary air, and the remaining The next 36 units are used as secondary air.

[0086] Table 1 Basic parameters of a 600MW boiler rotary air preheater

[0087]

[0088]

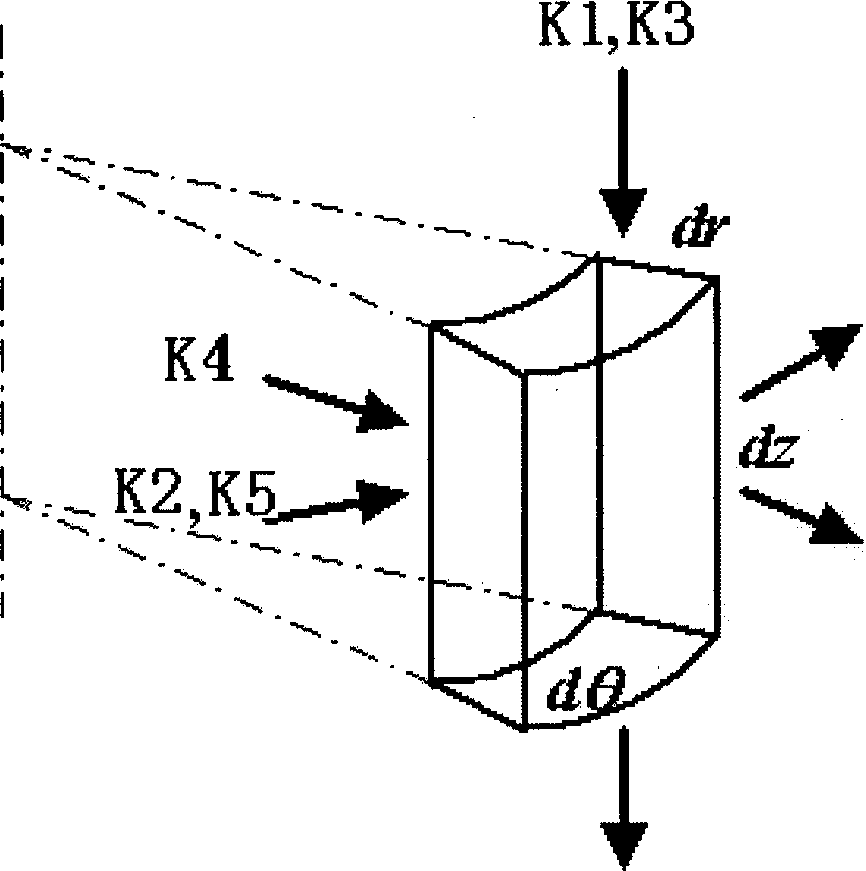

[0089] figure 2 with image 3 It is the three-dimensional temperature distribution diagram of the metal heat storage element in the start-stop stage of the 600MW three-compartment air preheater and the stable rated working condition, and the horizontal and total coordinates are expressed by the equivalent cycle and equivalent length respectively. Figure 4 For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com