Charging voltage control system and control method for laser beauty treating machine

A charging voltage and control system technology, applied in the field of charging voltage control system control and charging voltage control system, can solve problems such as increasing product cost, and achieve the effects of improving reliability, reducing production cost and saving port resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

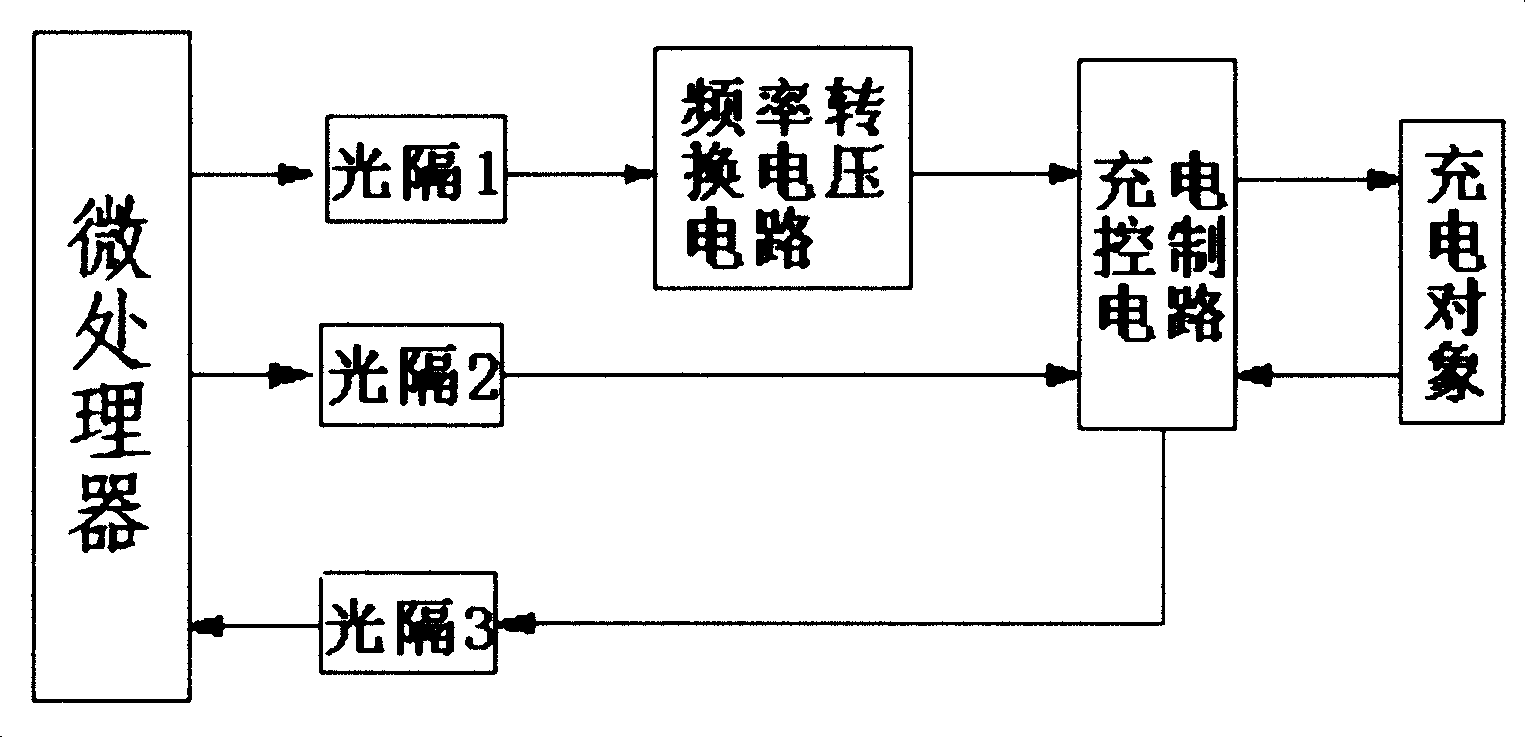

[0019] see image 3 , A charging voltage control system for a laser beauty machine of the present invention is composed of a microprocessor 1, an optical compartment 12, a frequency conversion voltage circuit 3, a control charging circuit 4, a charging object 5, an optical compartment 26, and an optical compartment 37. Wherein, microprocessor 1 adopts Winbond Company: (model is: 78E516); Optical isolation 12 (adopts ordinary optical isolation TLP521); Optical isolation 26 (adopts ordinary optical isolation TLP521); Optical isolation 37 (adopts ordinary optical isolation TLP521) ; The frequency conversion voltage circuit 3 (using LM331); the control charging circuit 4 adopts the charging board (model: ML-SL-DT01) produced by Wuhan Qizhi Laser Co., Ltd.

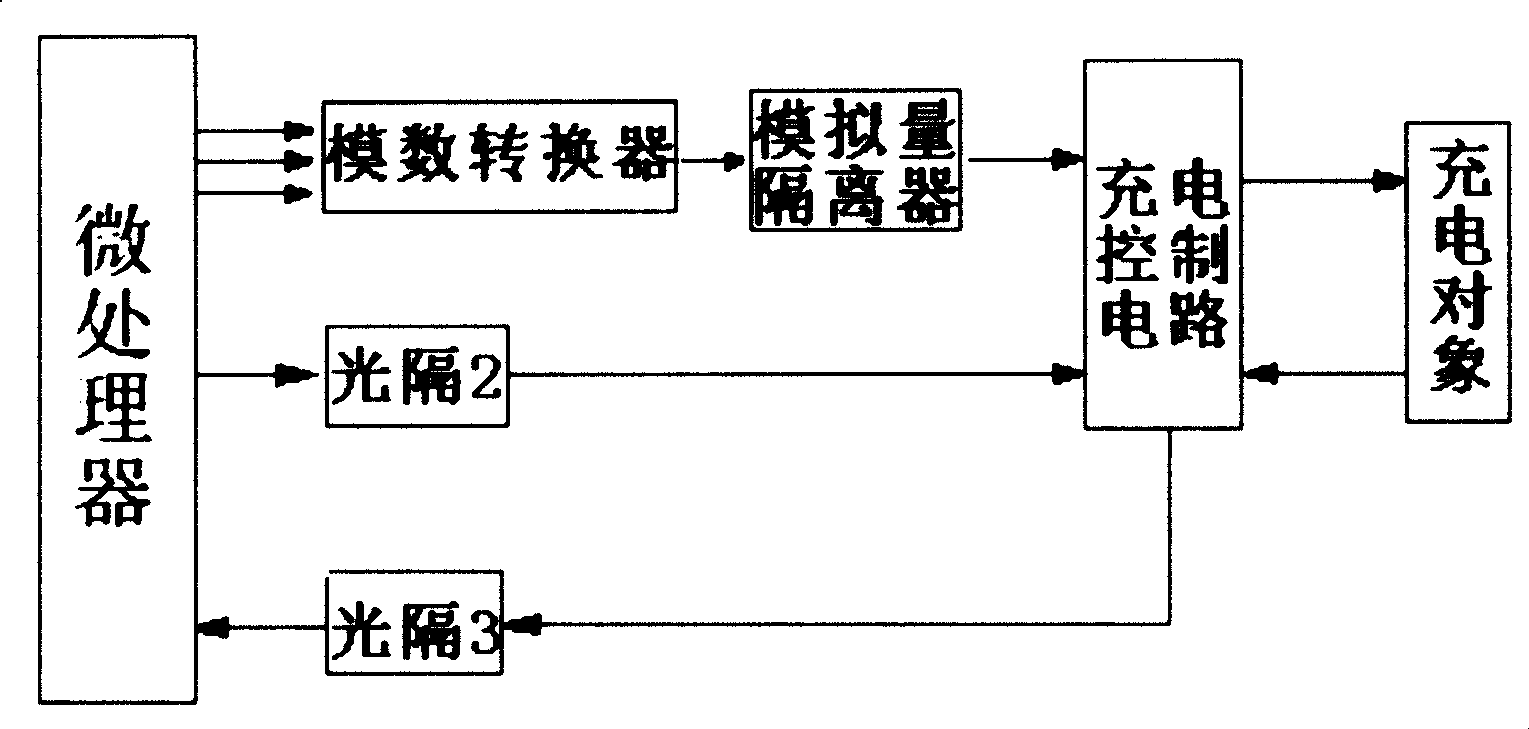

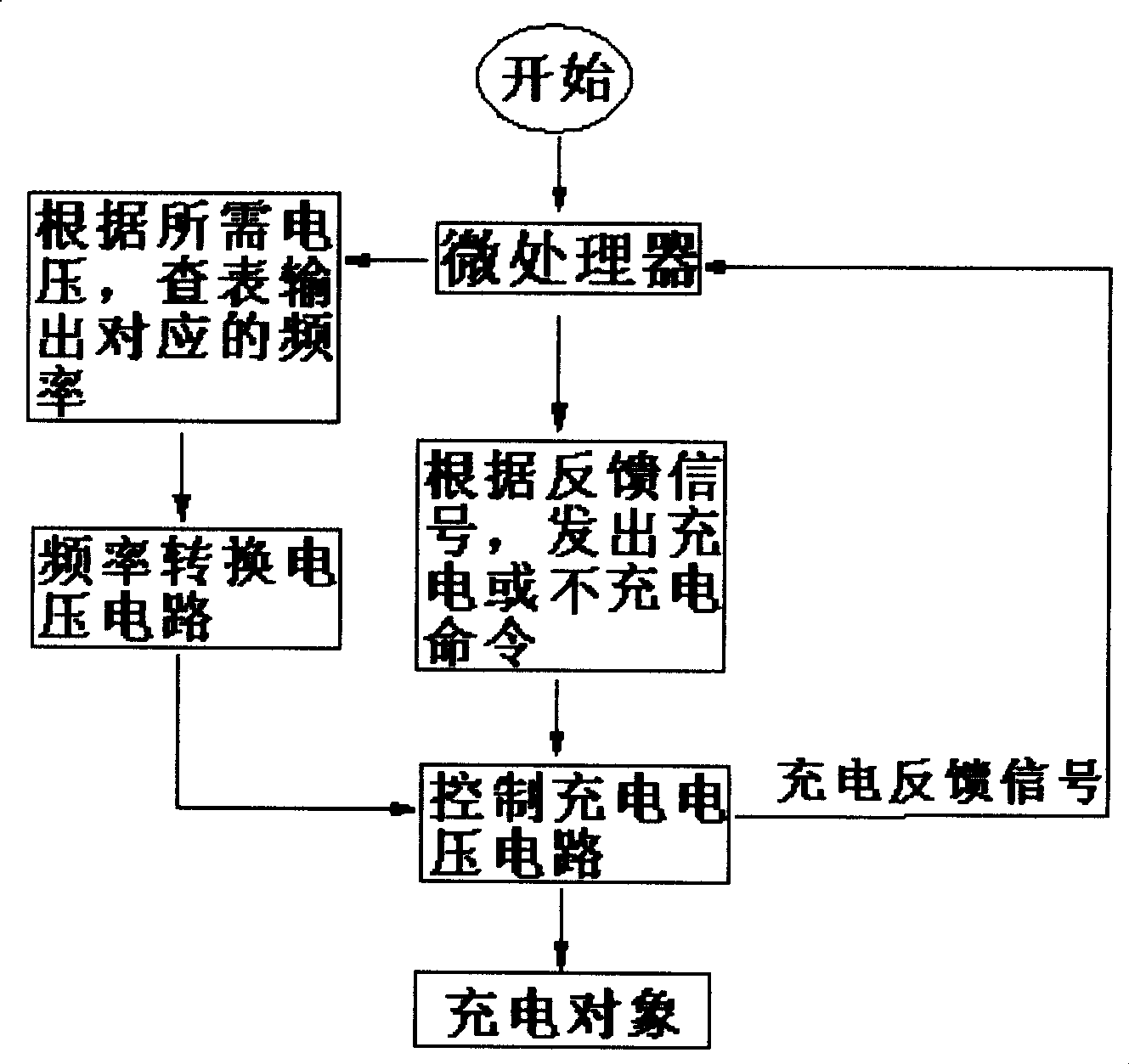

[0020] see figure 1 , 3, the control method of the charging voltage control syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com