Tool conveying mechanical arm

A manipulator and workpiece technology, applied in the field of workpiece conveying manipulators, can solve problems such as low transmission efficiency and complex transmission structure, and achieve the effects of reducing weight, simplifying transmission structure, and avoiding strong impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

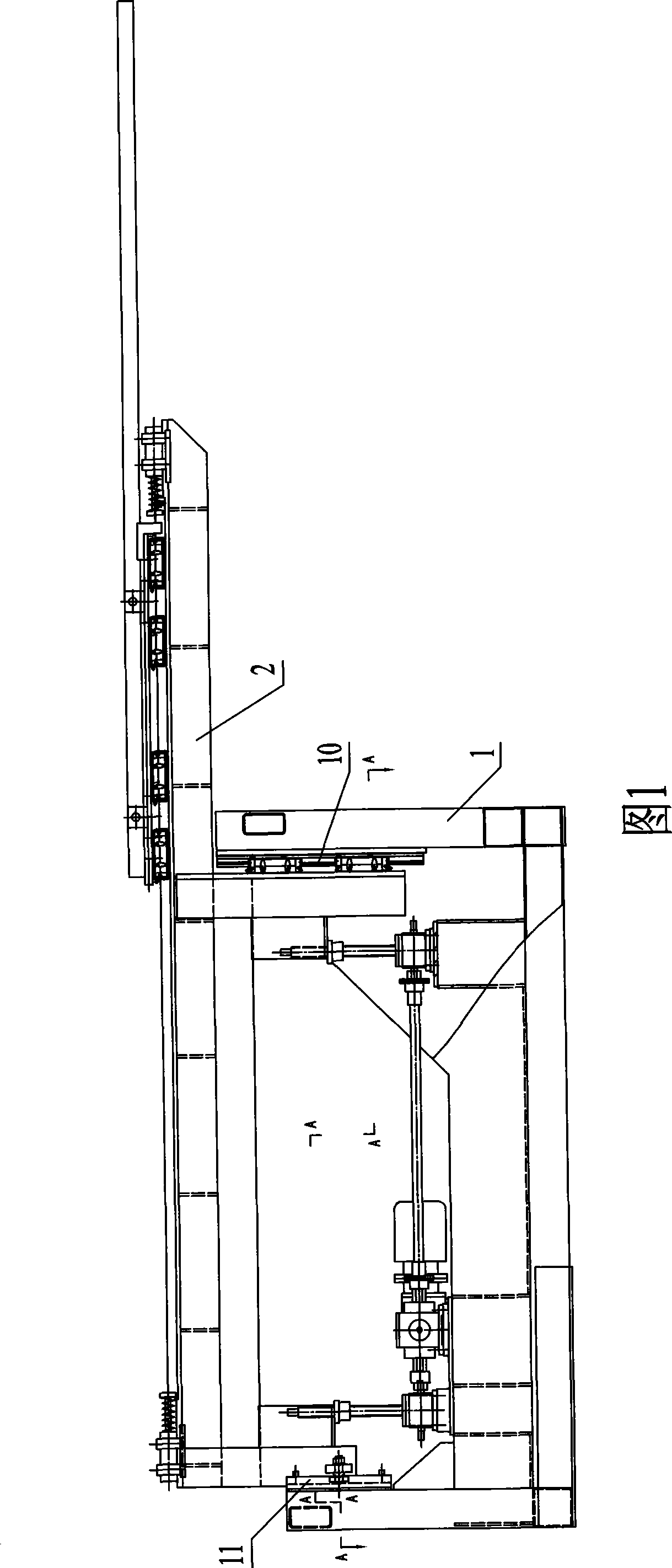

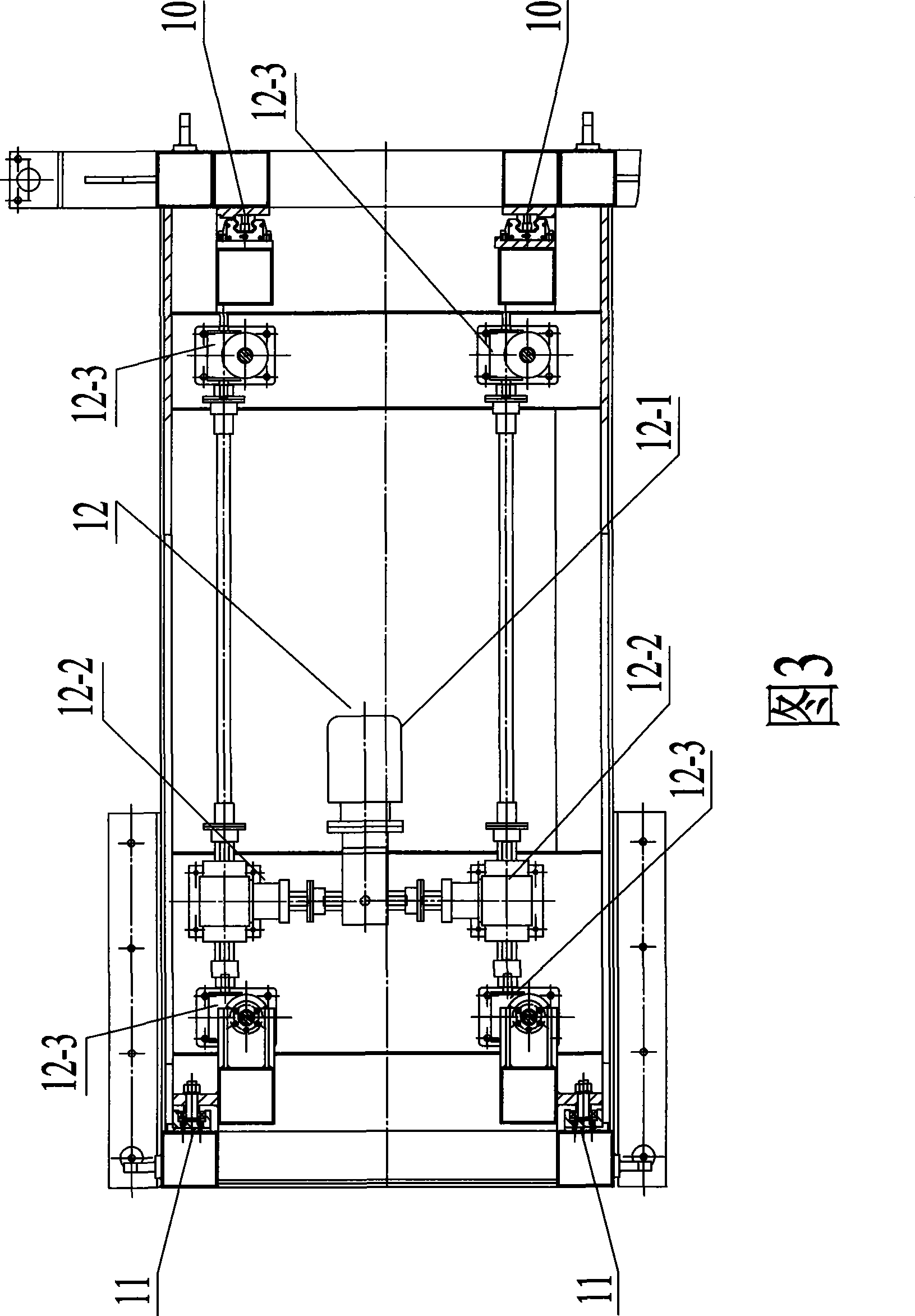

[0019] As shown in FIG. 1 , the workpiece conveying manipulator includes a first frame 1 and a second frame 2 , and the second frame 2 is connected to the first frame 1 .

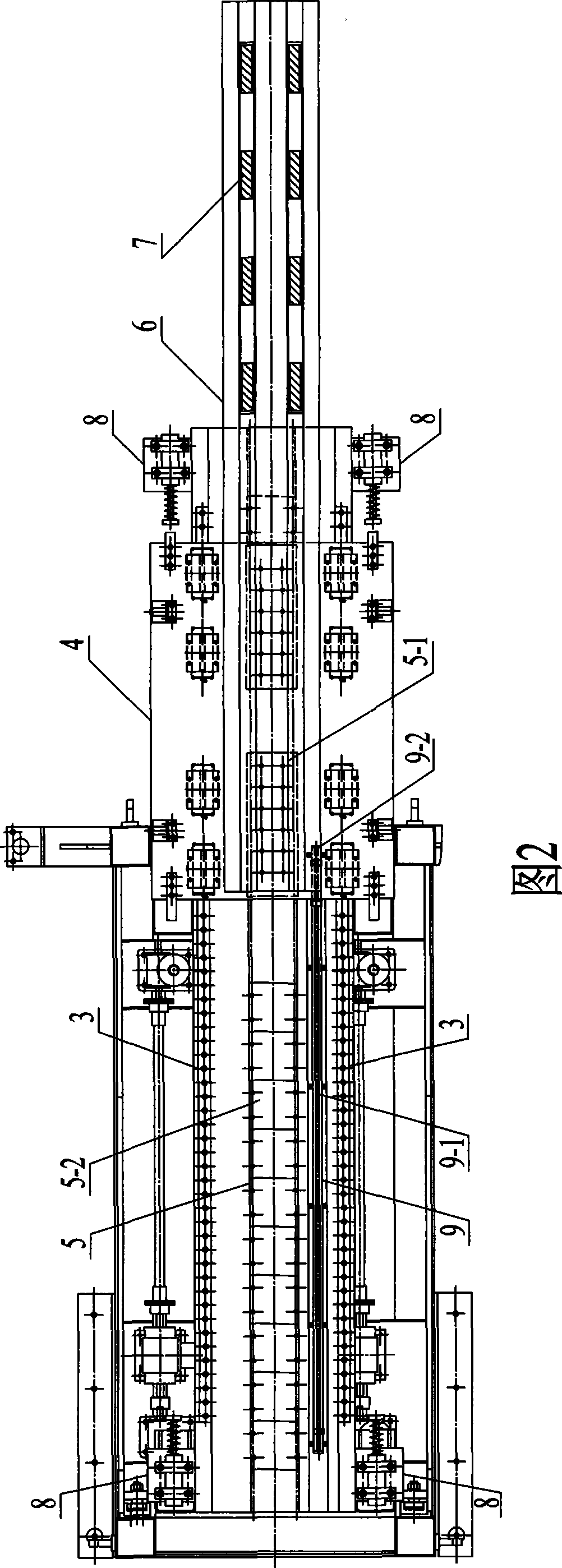

[0020] As shown in Figure 2, two parallel horizontal linear guide rails 3 are connected on the upper surface of the second frame 2, and a manipulator 4 is connected on the above-mentioned horizontal linear guide rail 3, and the manipulator 4 can move along the horizontal linear guide rail 3. Slide back and forth.

[0021] It also includes a linear motor 5 that can drive the manipulator 4 to reciprocate along the horizontal linear guide rail 3 . The primary 5 - 1 of the linear motor 5 is connected to the lower surface of the manipulator 4 , and the secondary 5 - 2 of the linear motor 5 is connected to the upper surface of the second frame 2 .

[0022] A receiving hand 6 is connected on the manipulator 4, and the clamping device 7 for fixing the workpiece is installed on the upper surface of the receiving ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com