Full automatic gel test machine and use thereof

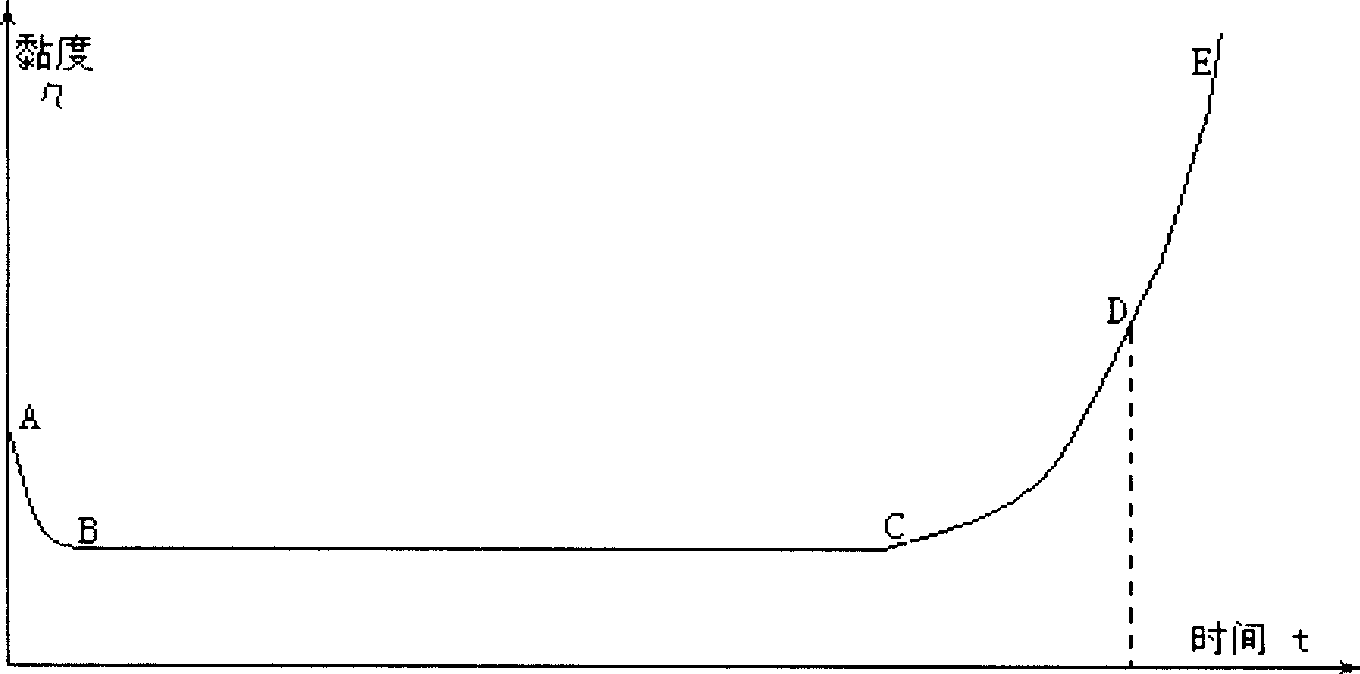

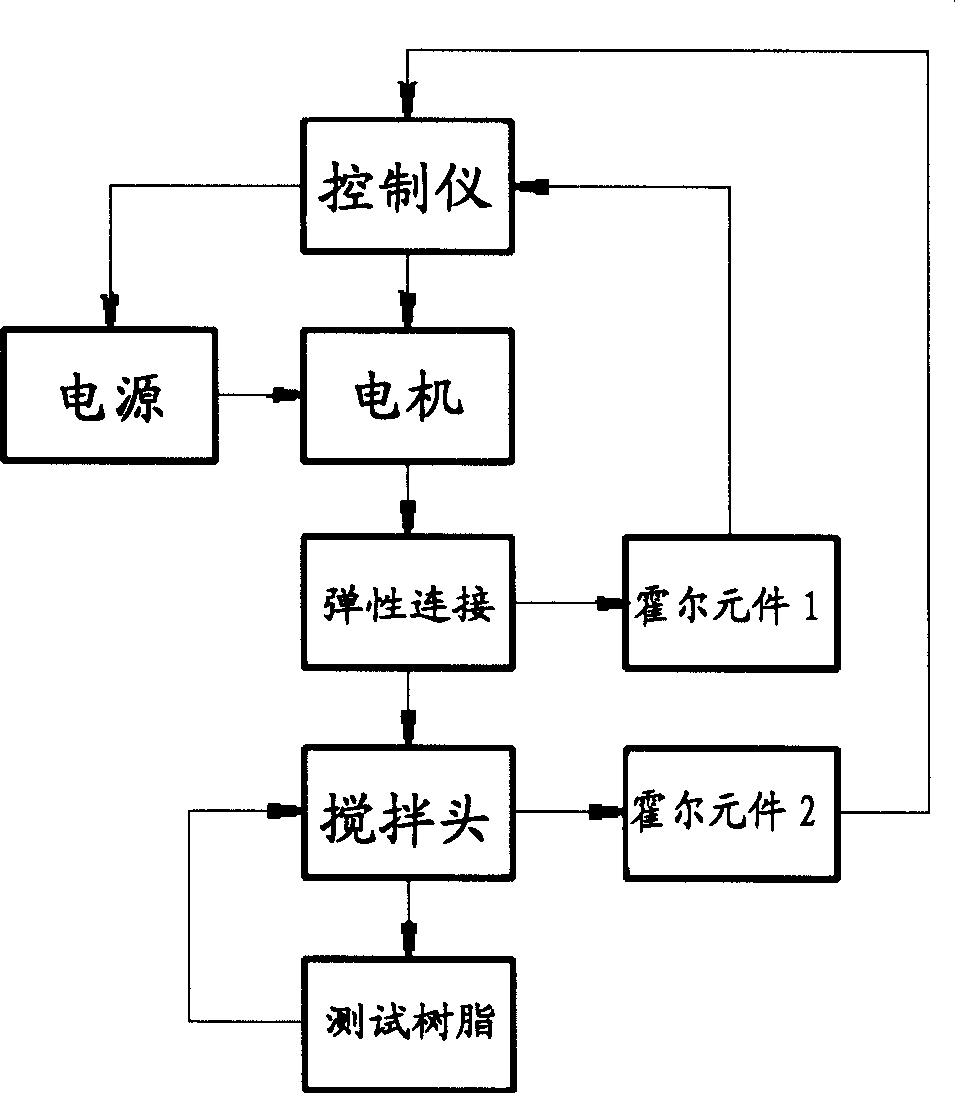

A gel test, fully automatic technology, applied in the direction of flow characteristics, material inspection products, measuring devices, etc., can solve the problems of inaccurate test results, large workload, and actual production inconsistency, so as to reduce human errors and improve work efficiency. , the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

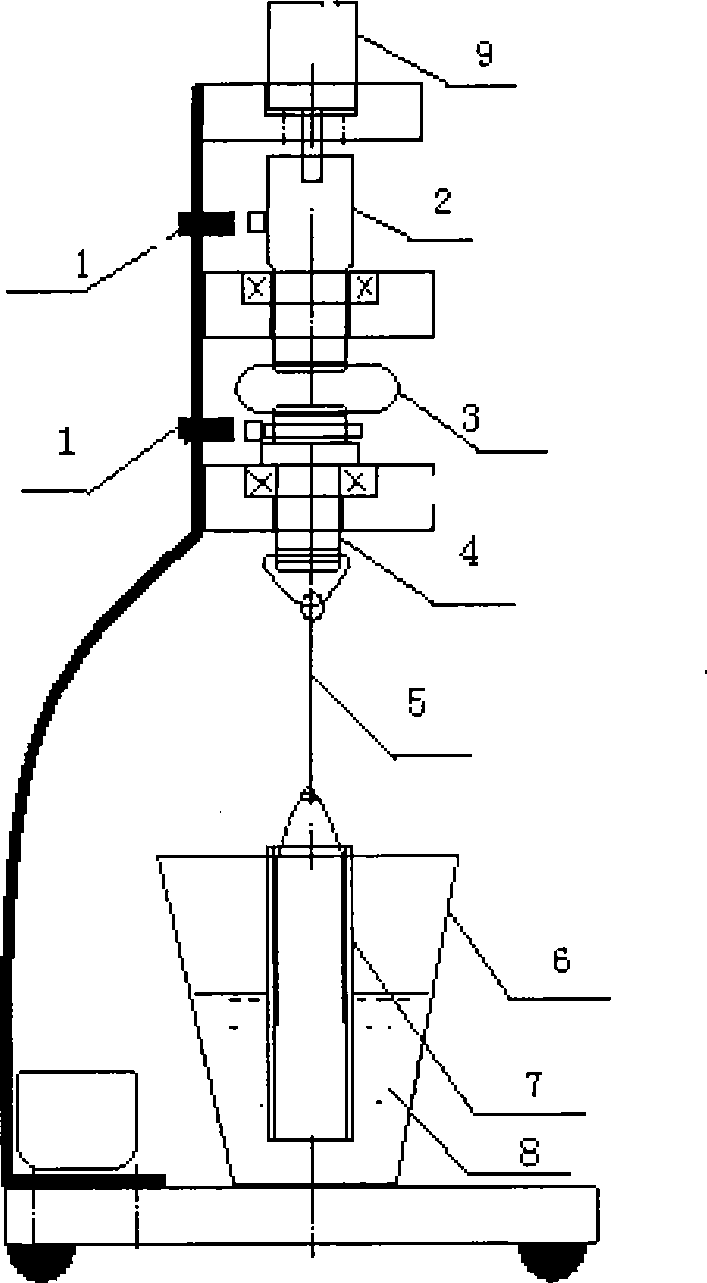

[0045] Example: Application of a fully automatic gel testing machine: Now take the test of the gel time of general-purpose unsaturated polyester resin 196 added with 1% initiator methyl ethyl ketone peroxide in an ambient temperature of 38° C. as an example.

[0046] ① Turn on the power of the automatic gel testing machine.

[0047] ②Adjust the temperature inside the thermostat 12 to 38°C through the increment key 23 and the decrement key 24 on the front panel of the thermostat controller.

[0048] ③ Put the weighed 100g thermosetting resin 8 into the incubator for ten minutes, and the temperature of the incubator 12 and the thermosetting resin 8 will reach a constant temperature.

[0049] ④ Add 1% methyl ethyl ketone peroxide initiator, which can also be cyclohexanone peroxide, benzoyl peroxide or amines or polyether amines.

[0050] ⑤Put the gel stirring head 7 into the thermosetting resin 8, select the stirring speed through the increment key 17, after selecting the speed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com