Manufacturing method of LED element

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, semiconductor devices, circuits, etc., can solve problems such as difficulty in etching, inability to etch slopes, etc., and achieve the effects of simple fabrication, improved light extraction rate, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The detailed content and technical description of the present invention will be further described by examples, but it should be understood that these examples are for illustrative purposes only, and should not be construed as limitations on the implementation of the present invention.

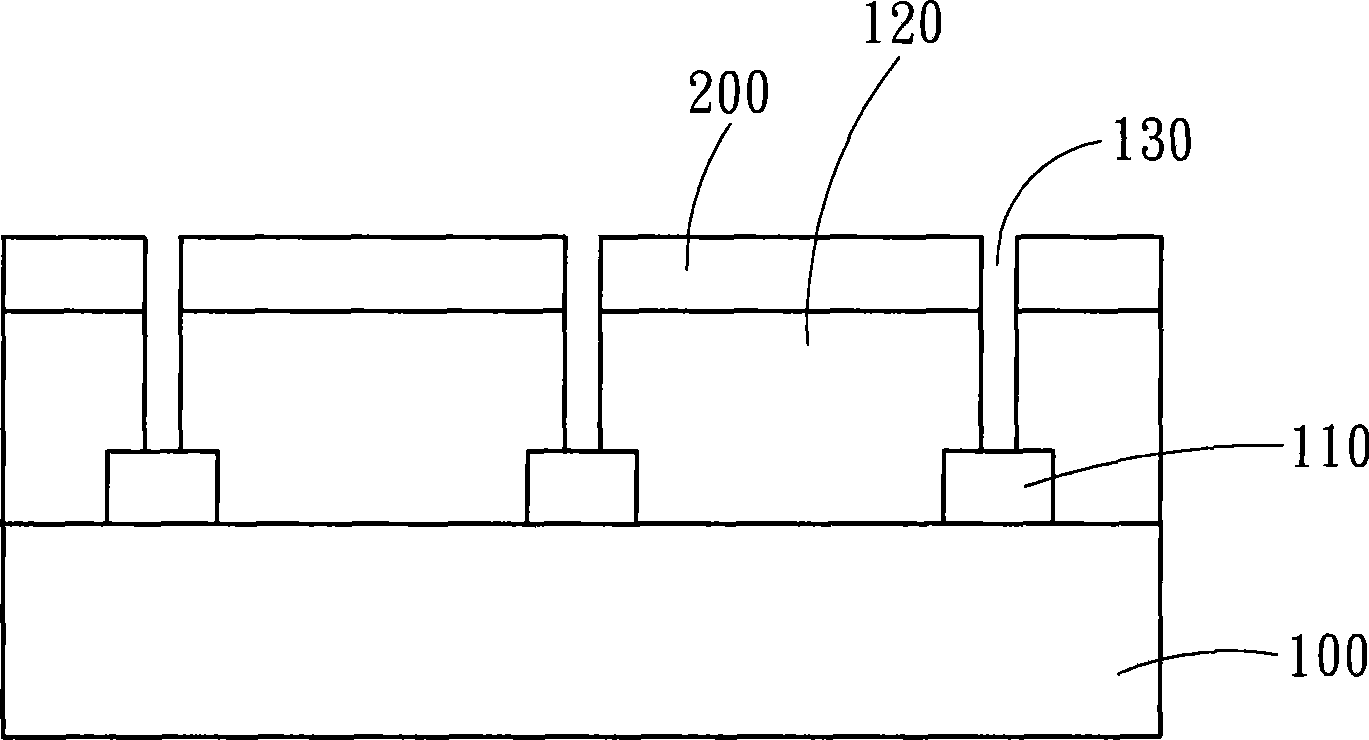

[0018] The invention utilizes the combination of the epitaxial method and the etching method to make the epitaxial layer structure of the light-emitting diode form a non-rectangular slope, improve the phenomenon of total reflection at the interface, and manufacture a light-emitting diode element with a high light extraction rate.

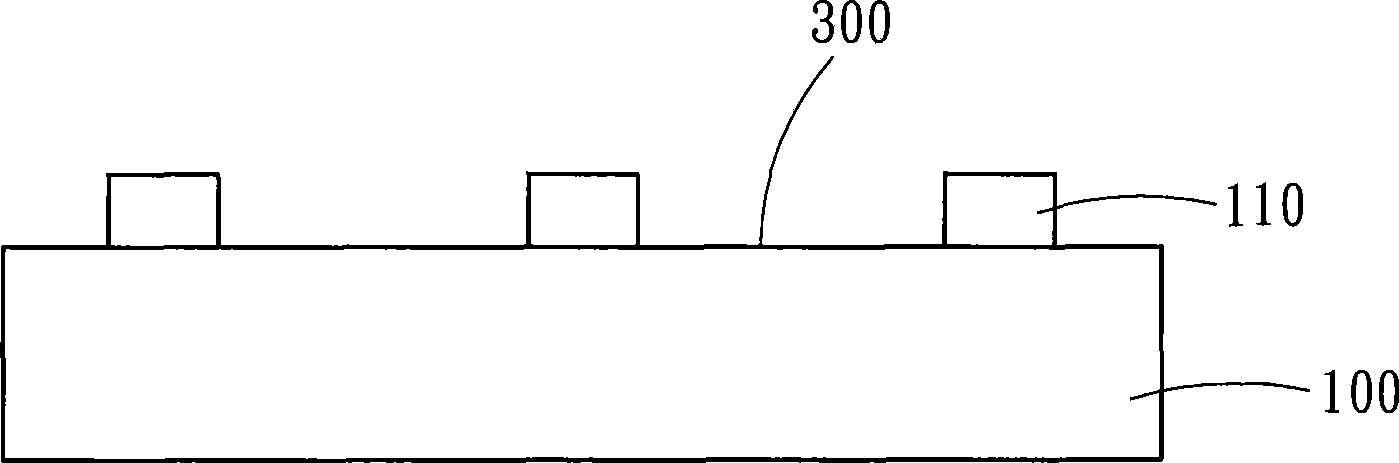

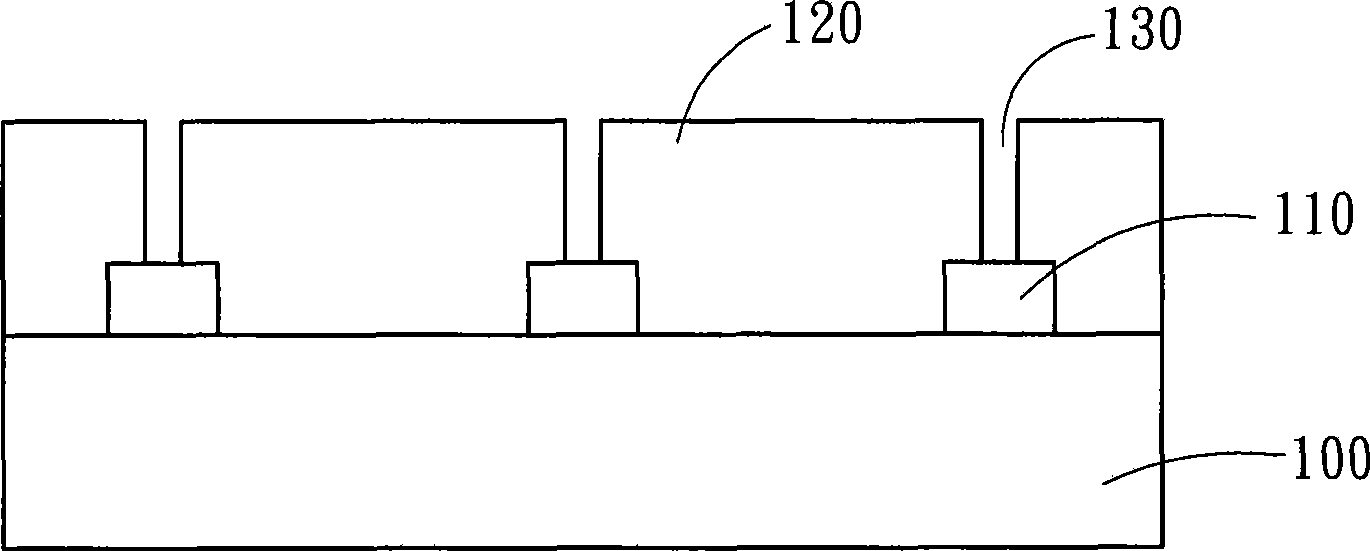

[0019] see Figure 1 to Figure 7 , is a schematic flow chart of the manufacturing method of the first embodiment of the present invention. The manufacturing steps of the first embodiment of the present invention include:

[0020] (a) A substrate 100 is provided, a shielding layer 110 is formed on the surface of the substrate 100, and the shielding layer 110 de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com