Capacitive sensing isolation using reversed biased diodes

A reverse bias, diode technology, used in weighing equipment using electrostatic balance, using electromagnetic/magnetic devices to transfer sensing components, measuring forces, etc., can solve problems such as affecting parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be described with reference to the accompanying drawings. In various embodiments of the invention described herein, like reference numerals refer to the same or similar parts throughout the drawings.

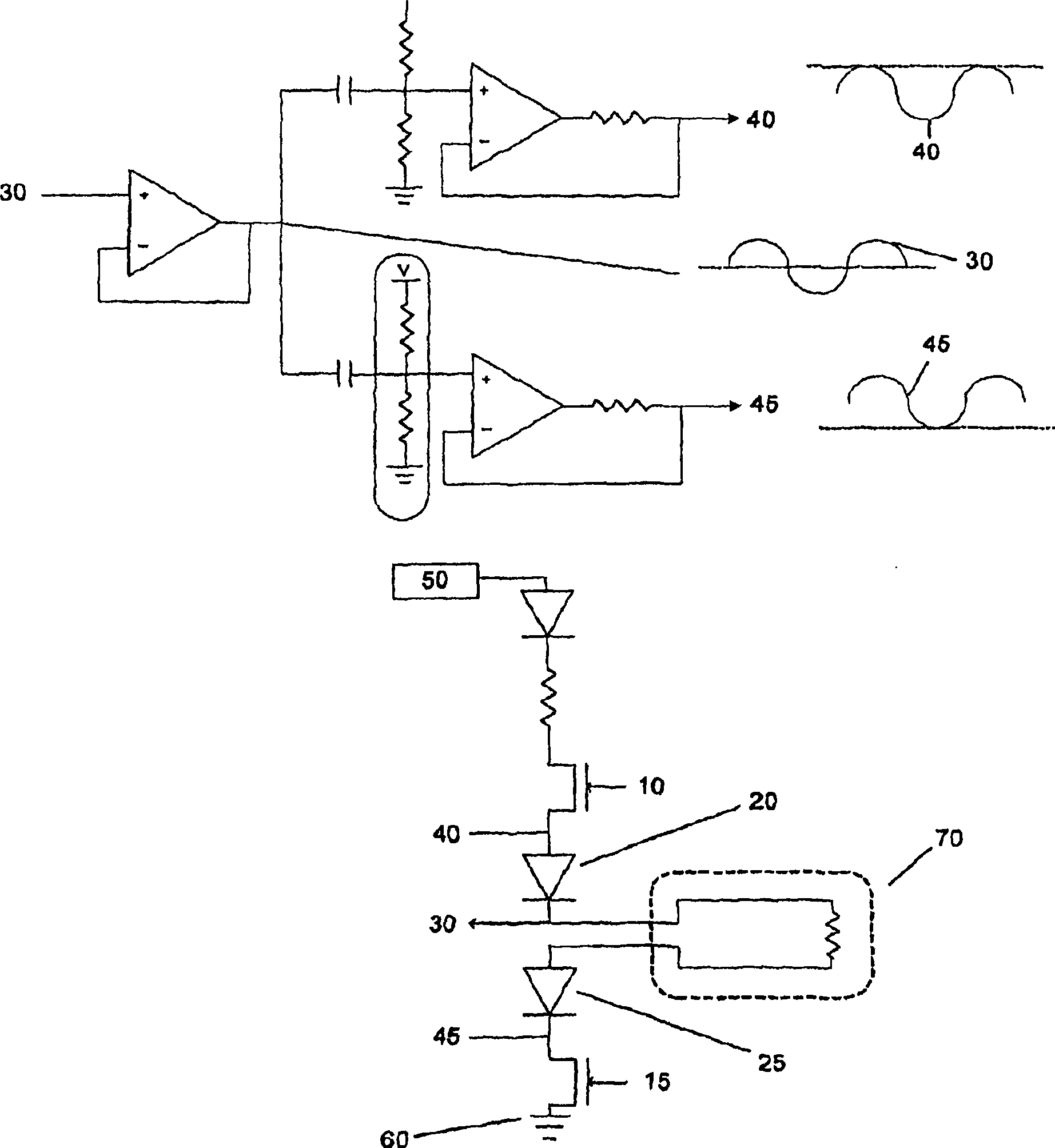

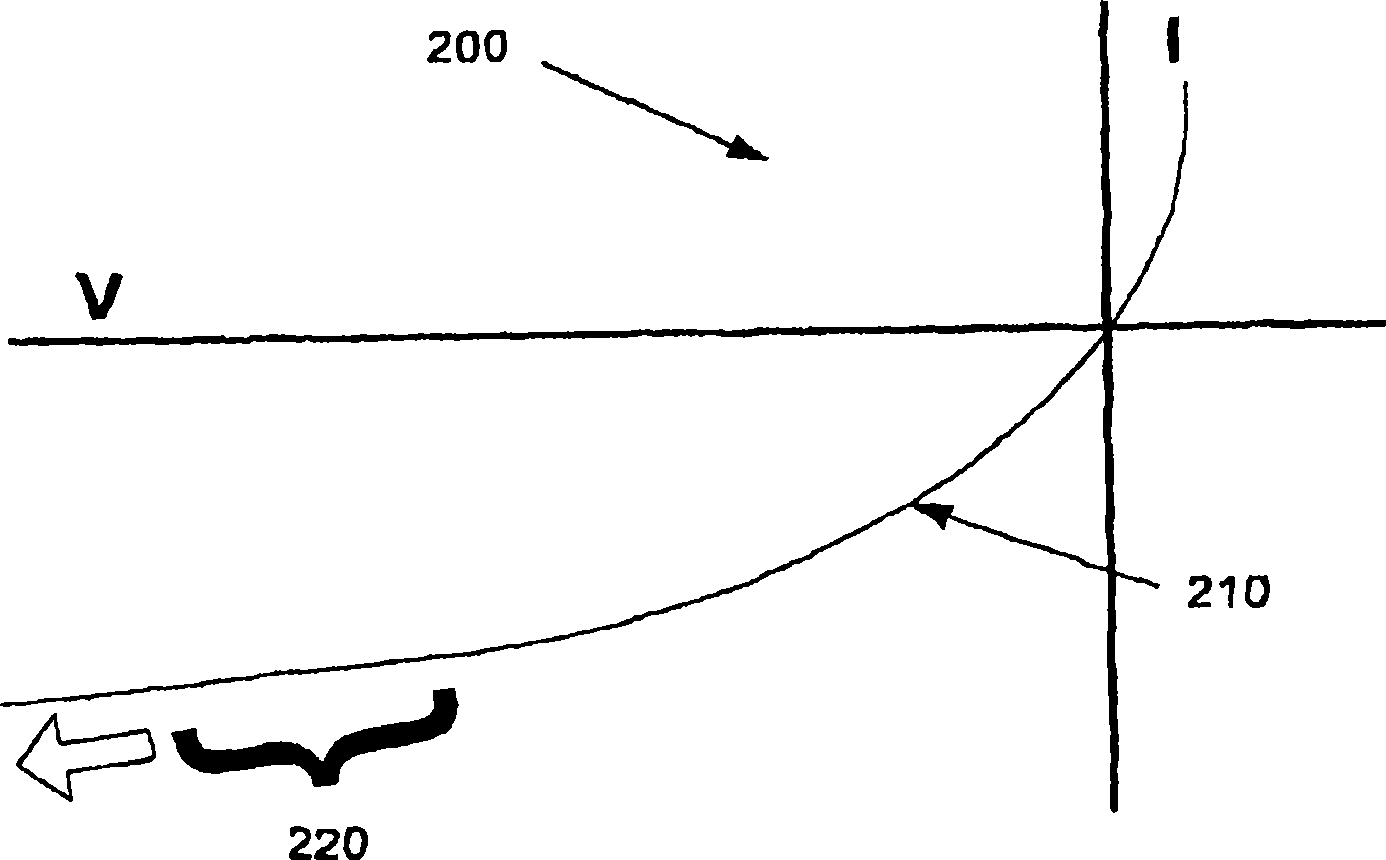

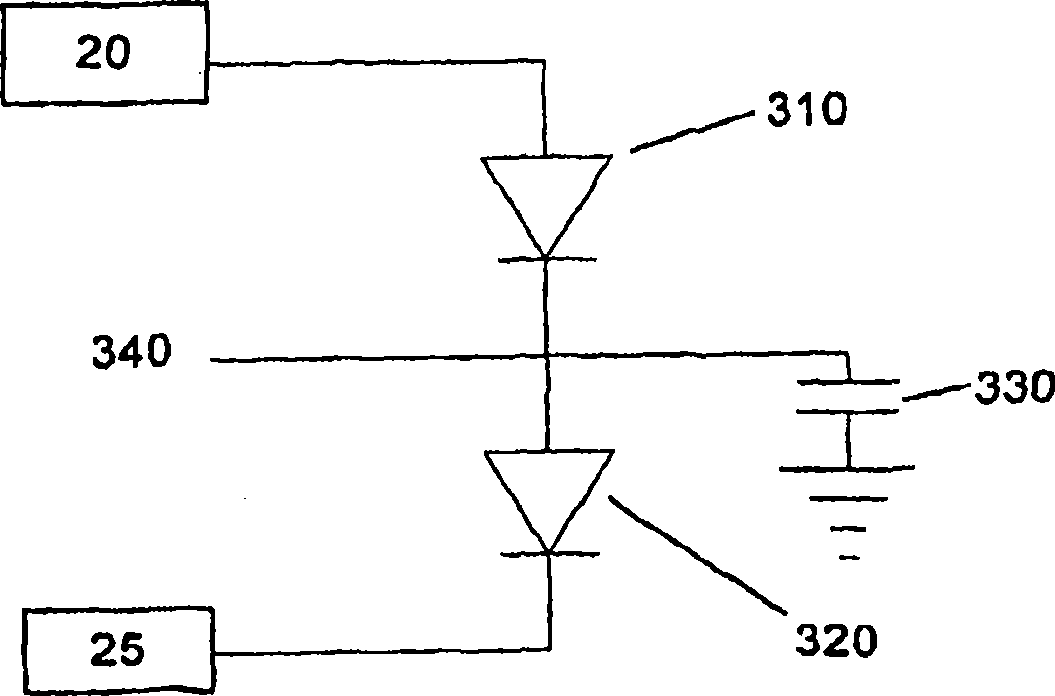

[0015] figure 1 A capacitive sensing system 1 according to one aspect of the invention is shown. Capacitive sensing signals for detecting occupants are generated by sensor / heating mat 70 . During sensing, the capacitive sensing system 1 ensures that the diodes 20, 25 do not conduct current by isolating the capacitive sensing signal 30 from the field effect transistors 10, 15 by utilizing the diodes 20, 25 and an applied reverse bias signal. . figure 1 The capacitive sensing signal 30 in is a sinusoidal signal, but can also be other time-varying signals. In the sense mode, a buffered sense signal with a DC offset smaller than the initial signal 40 is applied to the anode of the high-side diode 20; to the bias. Likewise, apply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com