Method for processing welding frame device using bolt, pun bush as positioning reference

A positioning datum, machining technology, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., to achieve the effect of reducing the difficulty of operation, high work efficiency, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The method of the present invention will be further described in detail with reference to the accompanying drawings and embodiments. However, the invention is not limited to the examples given.

[0012] After the frame is balanced on the special tooling before machining, the space size of each welded part is checked, and at the same time, each processing surface needs to have a machining allowance, and the three-dimensional space position of the frame is determined on this basis.

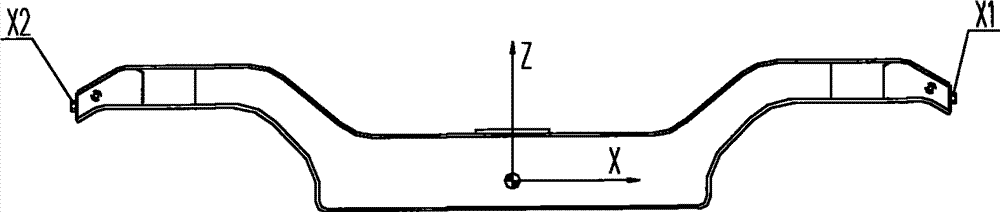

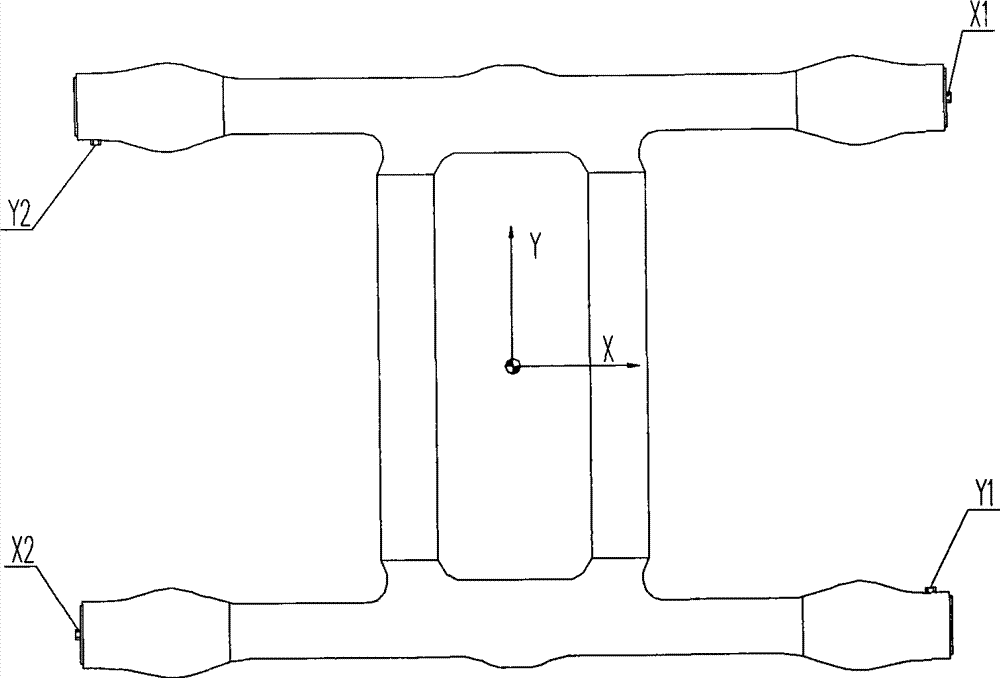

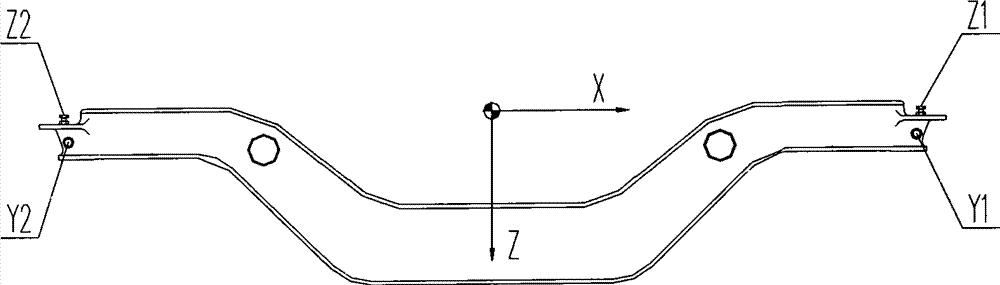

[0013] Such as figure 1 and figure 2 As shown, embodiment 1 is a schematic diagram of pin sleeve positioning on the AM96 frame as a positioning reference. The welding frame is machined according to the aforementioned 5 steps, and 4 pin sleeves X1, X1, X2, Y1, Y2, each direction has two pin sleeves parallel to each other and perpendicular to the other direction. On the tooling, there is a pin shaft that matches the pin sleeve. Use an edge finder to measure the central axis of the pin shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com