Cellular composite clean board

A clean and honeycomb technology, applied in the direction of building components, buildings, building structures, etc., can solve the problems of heavy weight of building boards, and achieve the effect of high flatness, high rigidity and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

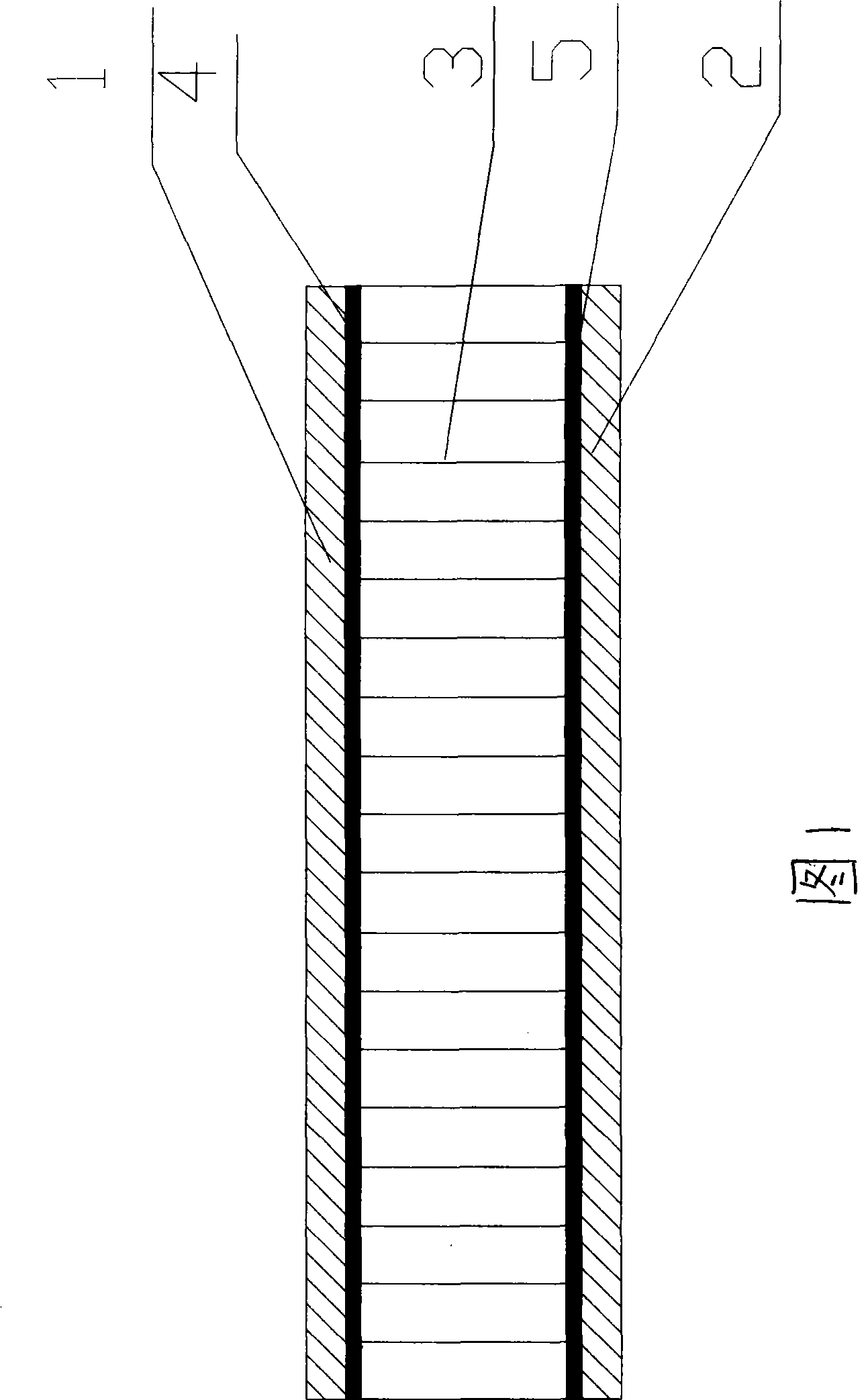

[0037] As shown in FIG. 1 , the present invention is a honeycomb composite clean panel. The clean panel includes an upper panel 1 and a lower panel 2 , and at least one layer of honeycomb core 3 is arranged between the upper panel and the lower panel.

[0038] From top to bottom, the clean board is respectively: upper panel 1, upper environmental protection adhesive layer 4, honeycomb core layer 3, lower environmental protection adhesive layer 5 and lower panel 2, and the honeycomb core layer passes through the upper and lower environmental protection layers respectively. The adhesive layer is combined with the panel and between the two panels.

[0039] The two panels can be color steel plates, density boards, particle boards, stone boards, glass steel plates or plastic boards. The two panels can be made of the same material or different materials.

[0040] The environmentally friendly adhesive is PVR glue, latex or cornstarch modified glue.

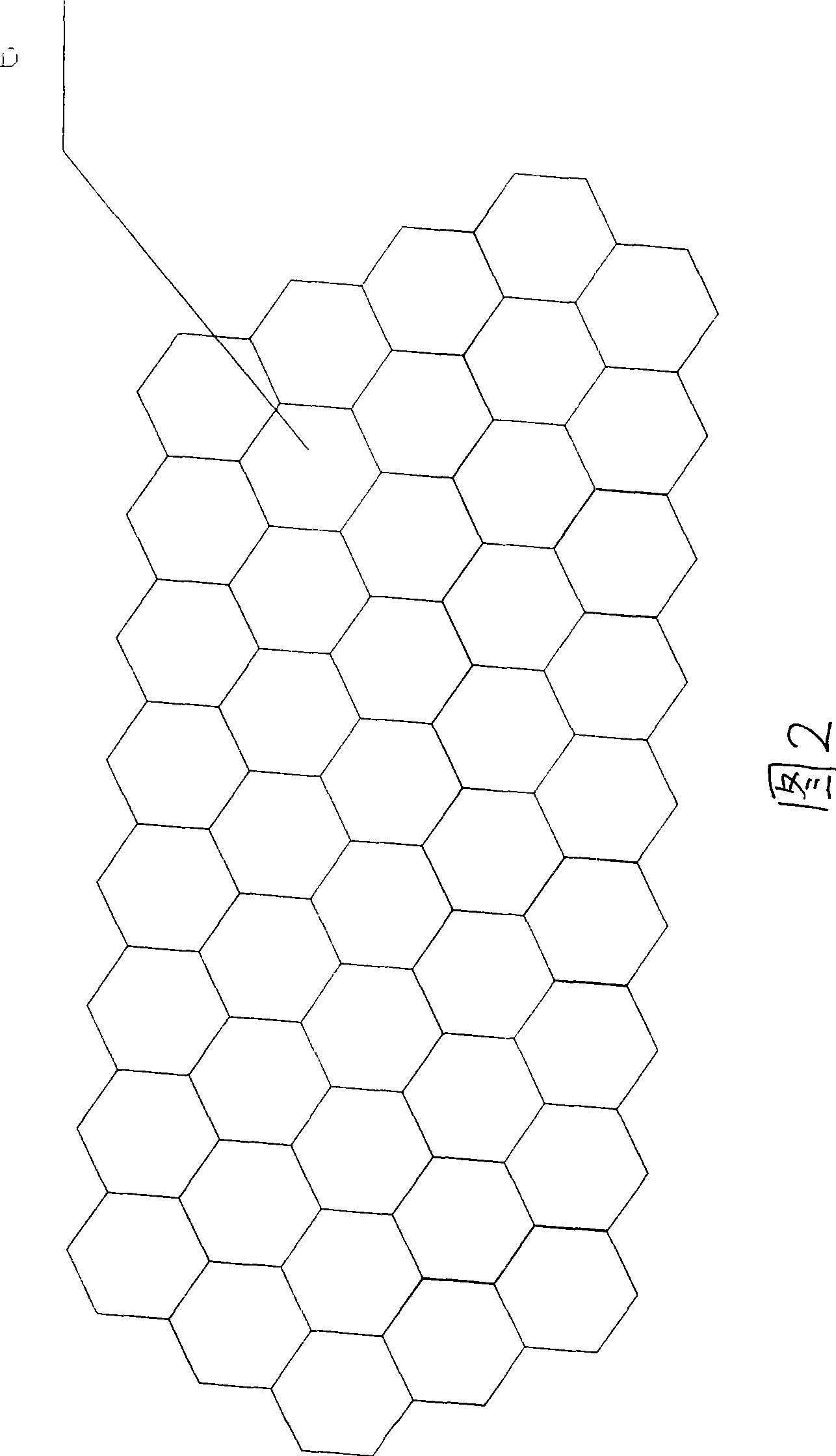

[0041] The honeycomb core is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com