Engineering vehicle power system matching method and system

A technology for engineering vehicles and power systems, applied in engine components, engine control, machines/engines, etc., can solve the adverse effects of engine life, combustion performance, fuel economy and emissions, cannot meet the requirements of large-scale heat dissipation changes, engine system The heat dissipation is very different, so as to reduce emissions, extend component life, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

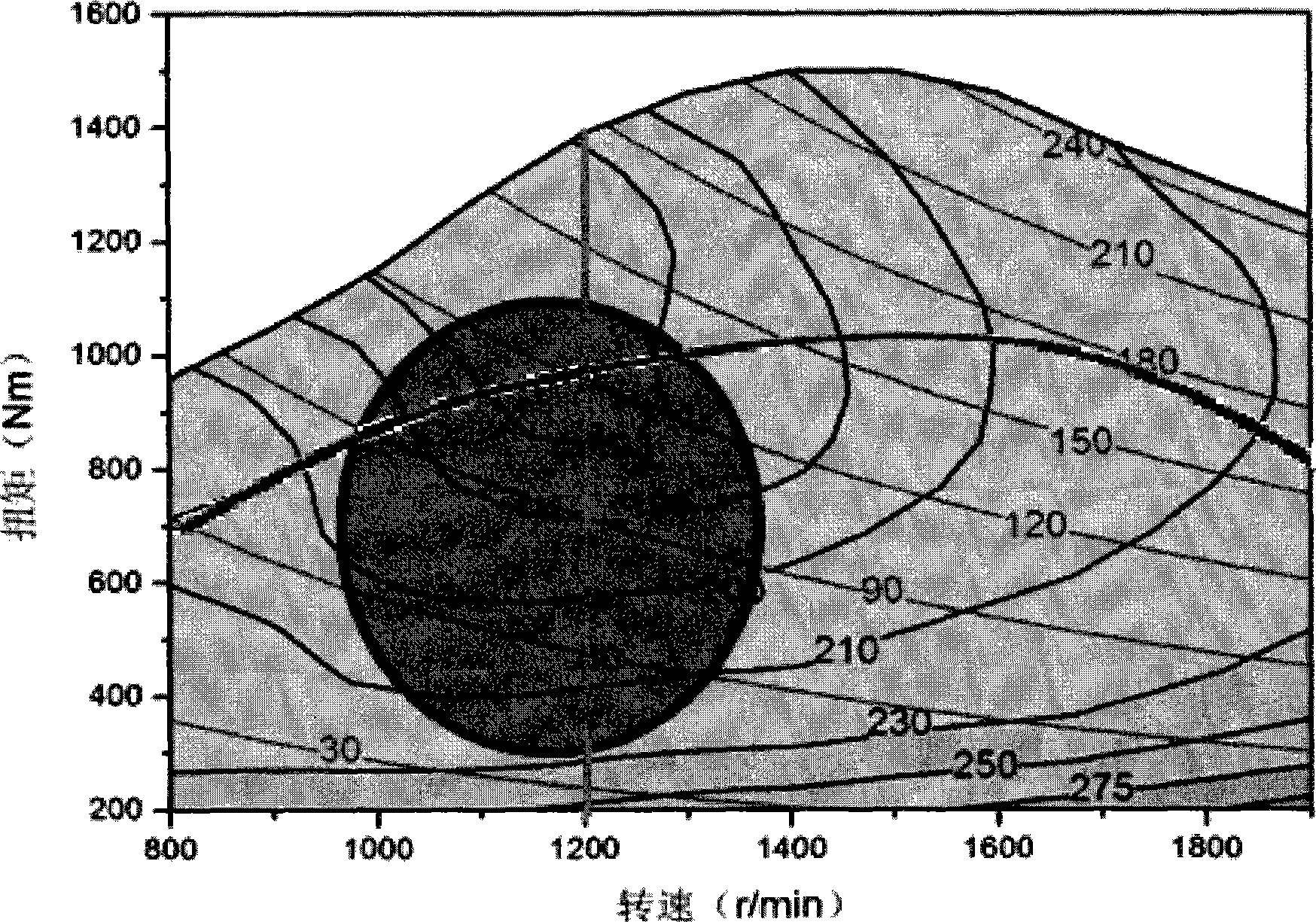

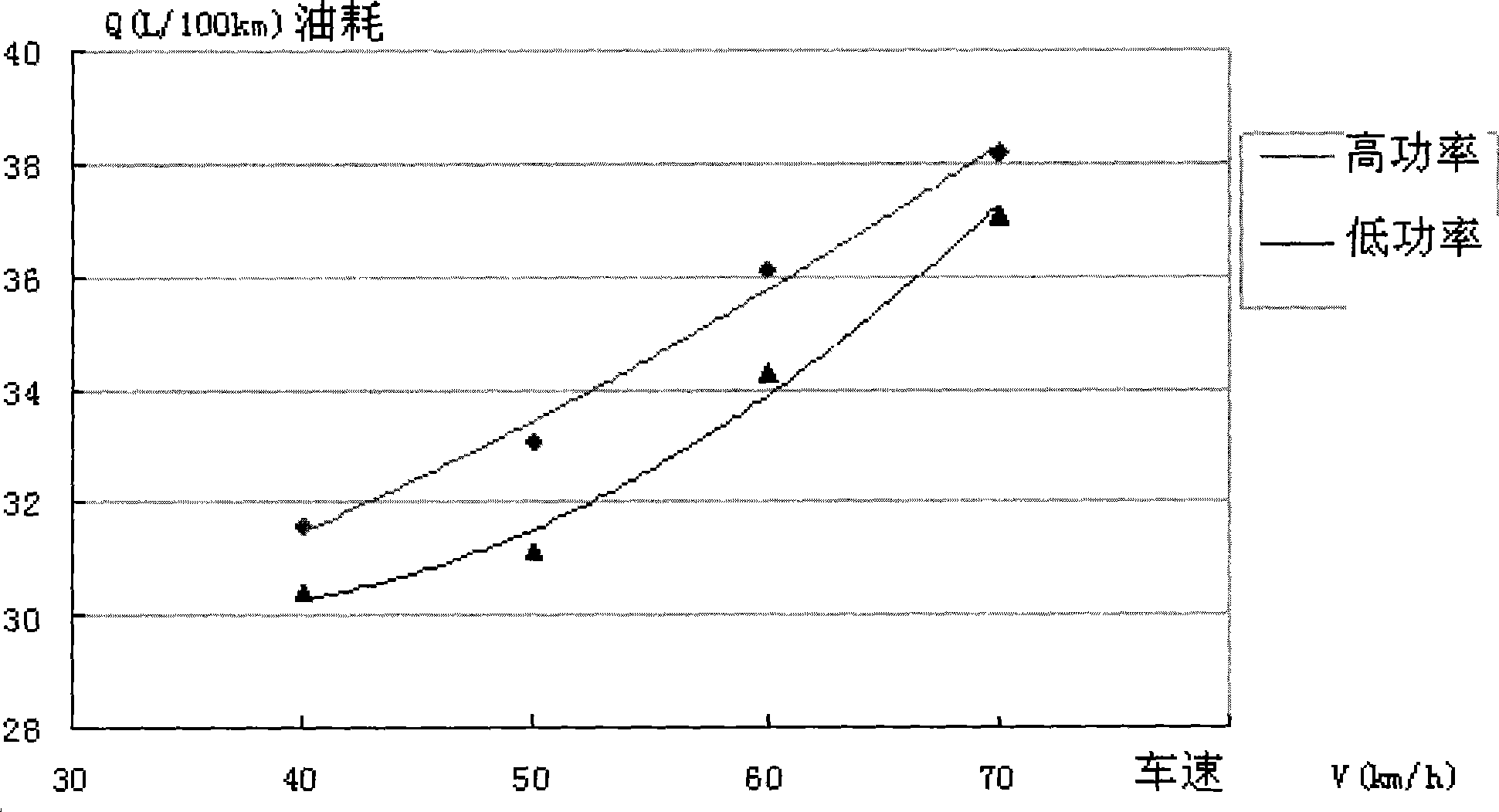

[0044] The basic idea of the present invention is to switch the engine output torque to the engine calibration torque corresponding to the current working condition under different load conditions, so that the engine runs on the engine external characteristic curve corresponding to the current working condition; and, under different output power Next, by sensing the current temperature of the engine, the speed of the engine cooling fan is controlled, so that the engine and its cooling system are at the most suitable temperature.

[0045] The principle of the present invention will be briefly described below.

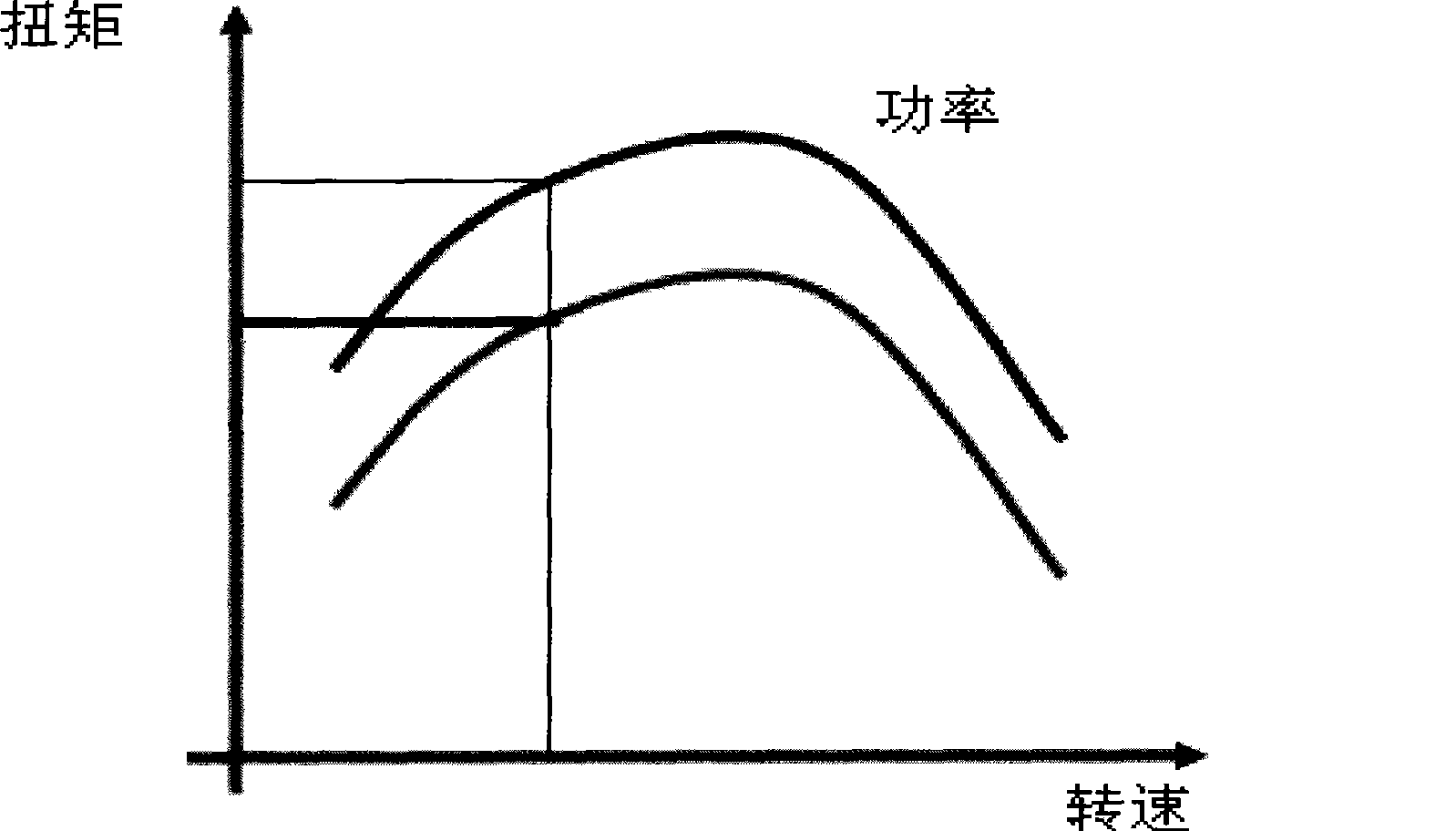

[0046]As we all know, torque and power are important indicators to characterize the power performance of an engine. Among them: the torque output by the engine through the flywheel is called the effective torque, represented by T, and the unit is N m. The effective torque is balanced with the resistance torque applied to the crankshaft of the engine by the outside. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com