Handtool with improved gas combustion

A hand-held tool and gas technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of expensive and inconvenient tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

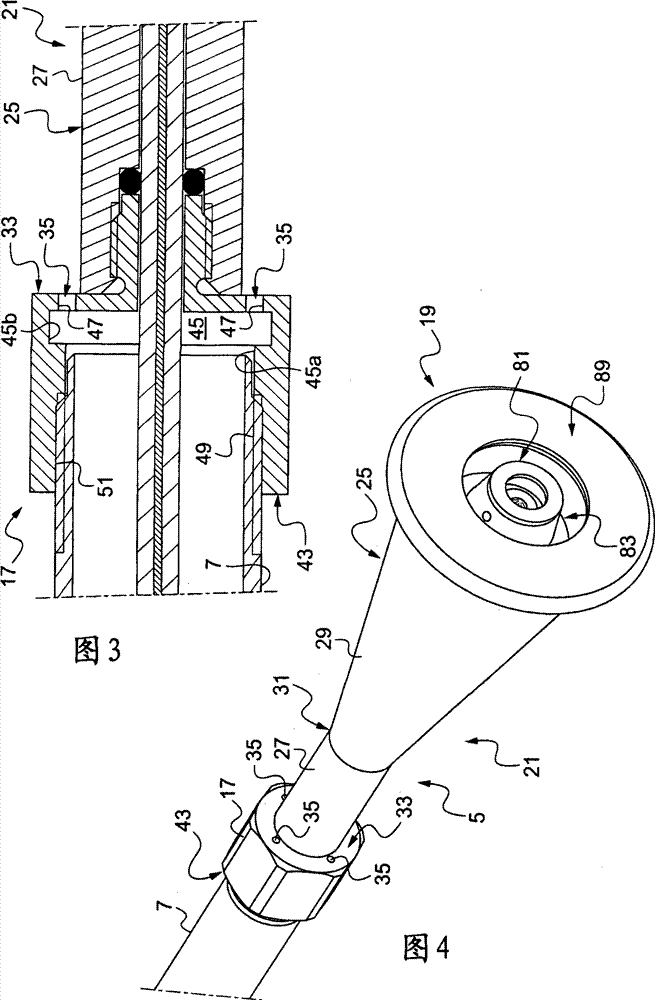

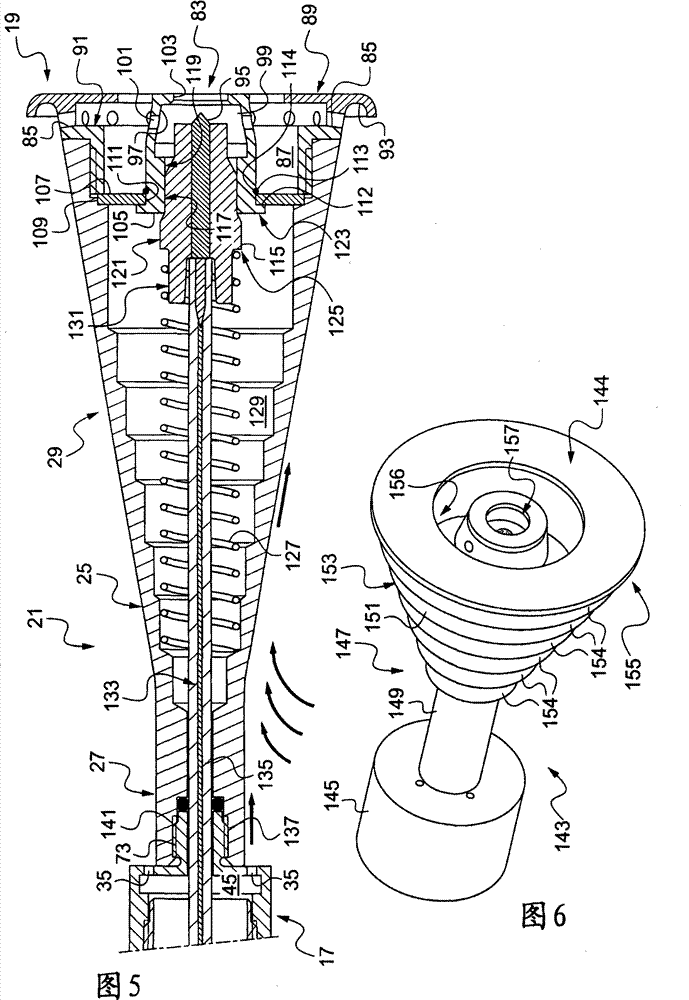

[0034] The accompanying drawings will not only serve to supplement the invention, but also contribute to the description of the invention where necessary.

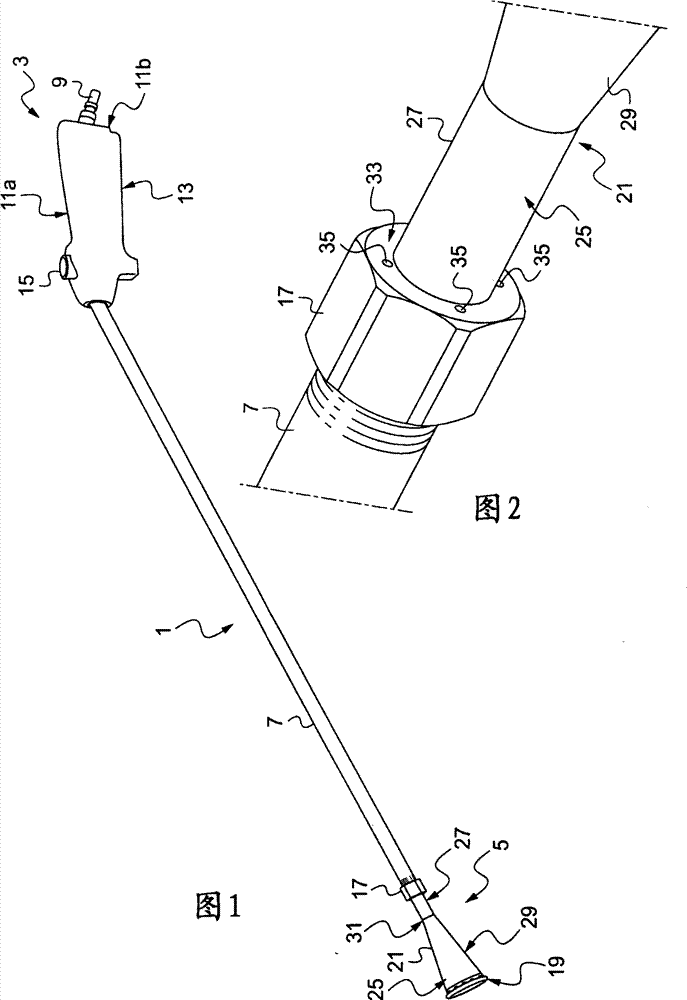

[0035] figure 1 A flame spray gun 1 is shown as an example of a gas combustion hand tool embodying the invention.

[0036] The flame spray gun 1 basically comprises a grip handle 3 and a gas burner 5 , which are connected to each other by a gas flow pipe 7 .

[0037] The handle 3 can be connected to a gas source through a gas connector 9, the pressure of the gas source is reduced to the required operating pressure, and the gas connector 9 is arranged to receive the end of a hose (not shown) connected to the gas source (not shown) .

[0038] The handle 3 comprises in particular a grip sleeve. This sleeve comprises an upper part 11a designed to accommodate the palm of the user and a lower part 11b from which a control lever 13 protrudes downwards, enabling the actuation of a gas supply (not shown) located in the handle 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com