Electrochemical parameter automatic detection apparatus of high-temperature high-pressure reactor

An automatic detection device, high temperature and high pressure technology, applied in the field of electrochemistry, can solve problems such as incomplete experimental data and errors, and achieve the effects of complete and accurate measurement data, easy operation, and safe structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

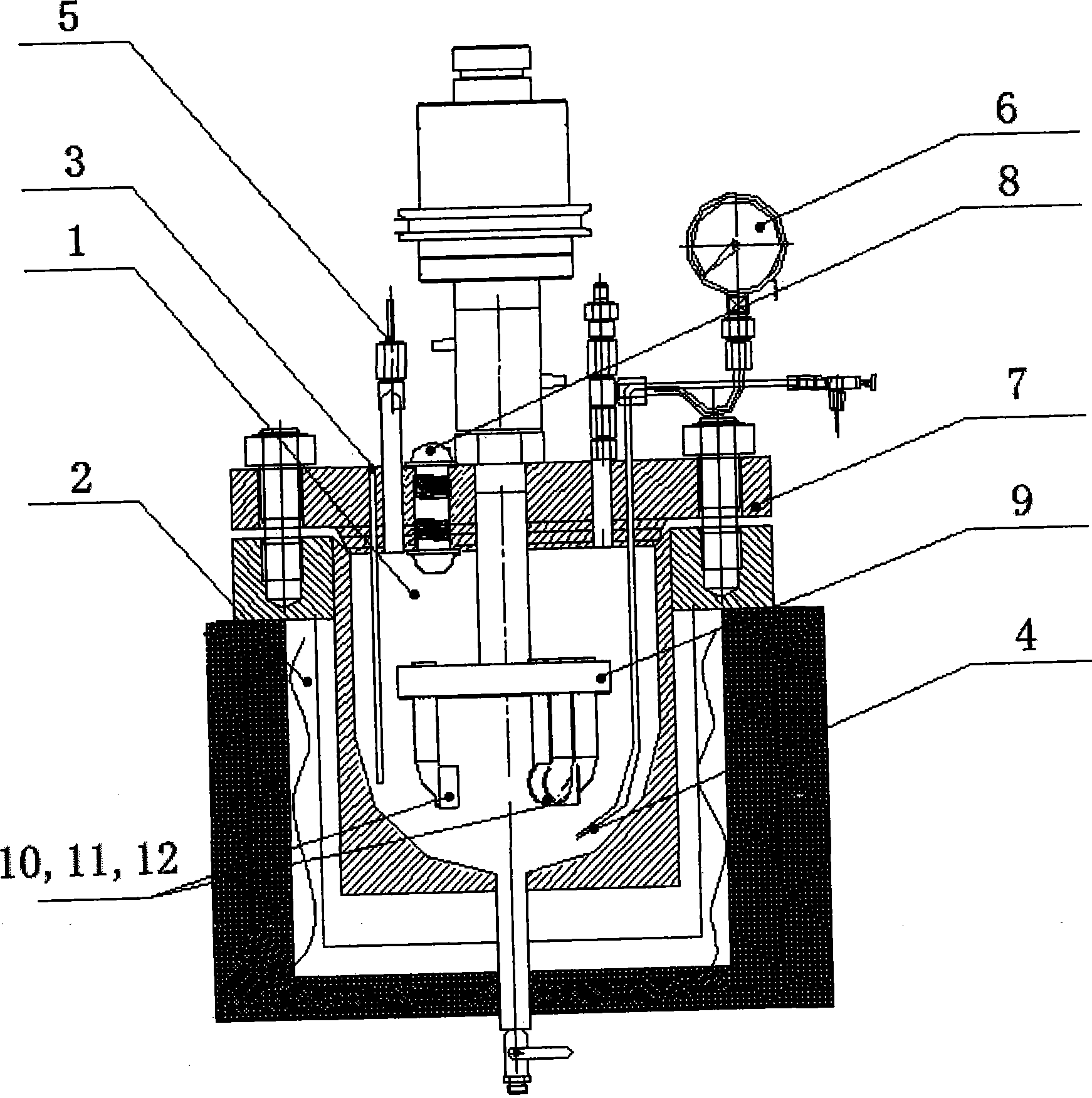

[0019] Embodiment 1: install the high-temperature and high-pressure reactor to carry out the electrochemical test (three working electrodes) under the unmanned state of the three-electrode system

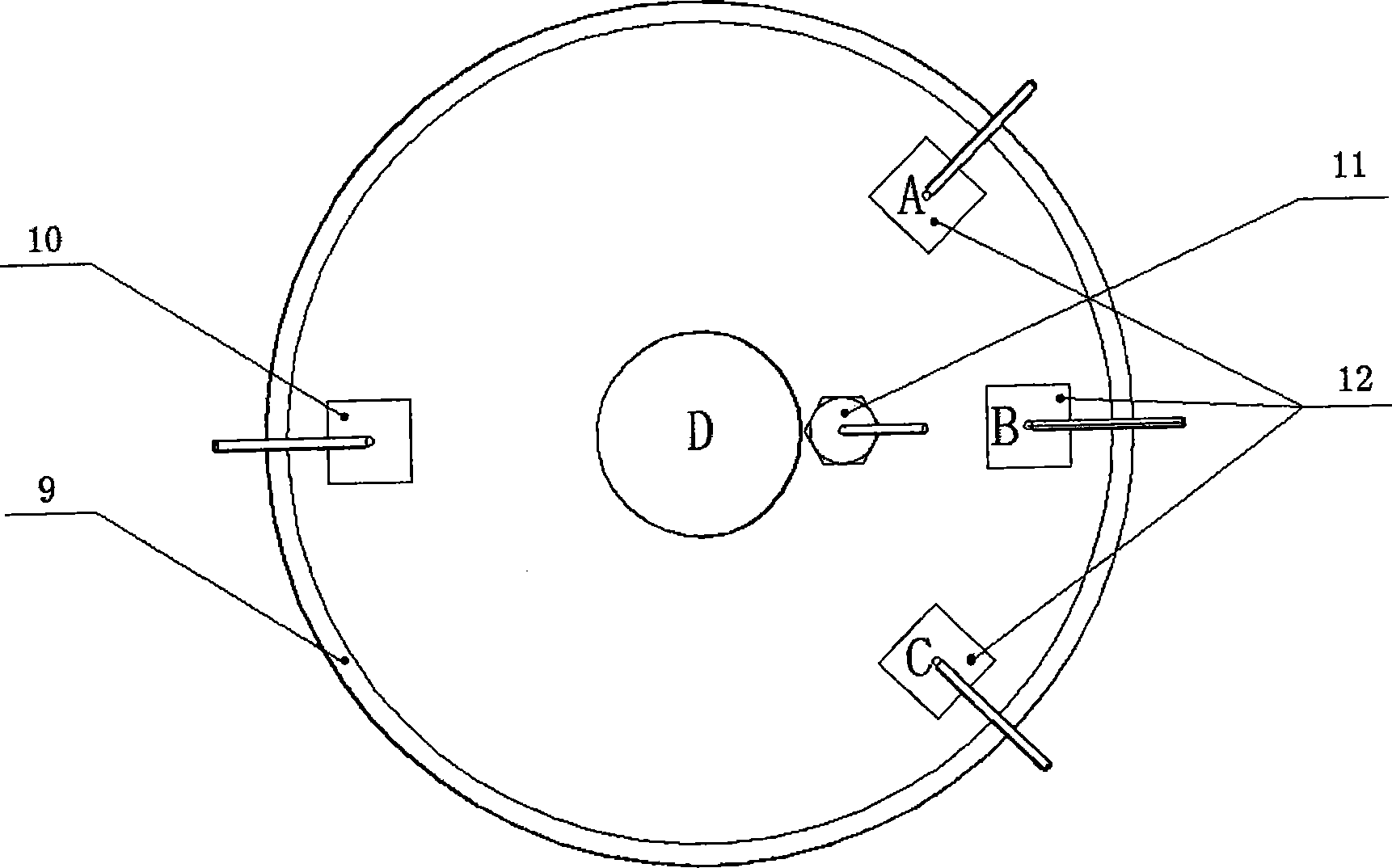

[0020] 1. Connect the reference electrode 11, the auxiliary electrode 10, and the three working electrodes 12 to the wires at the bottom of the wire fixing bolts 8 and seal them with epoxy resin.

[0021] 2. Fix the wire fixing bolt 8 to the bottom of the reactor cover 7, and install each electrode on the electrode fixing mold 9 inside the reactor cavity 1, according to figure 2 Position shown is correct.

[0022] 3. Install the cover body 7, and carefully place the cover body 7 on the kettle body according to the fixed position. When tightening the main nut, tighten it diagonally and symmetrically for several times gradually. Use even force to achieve a good seal.

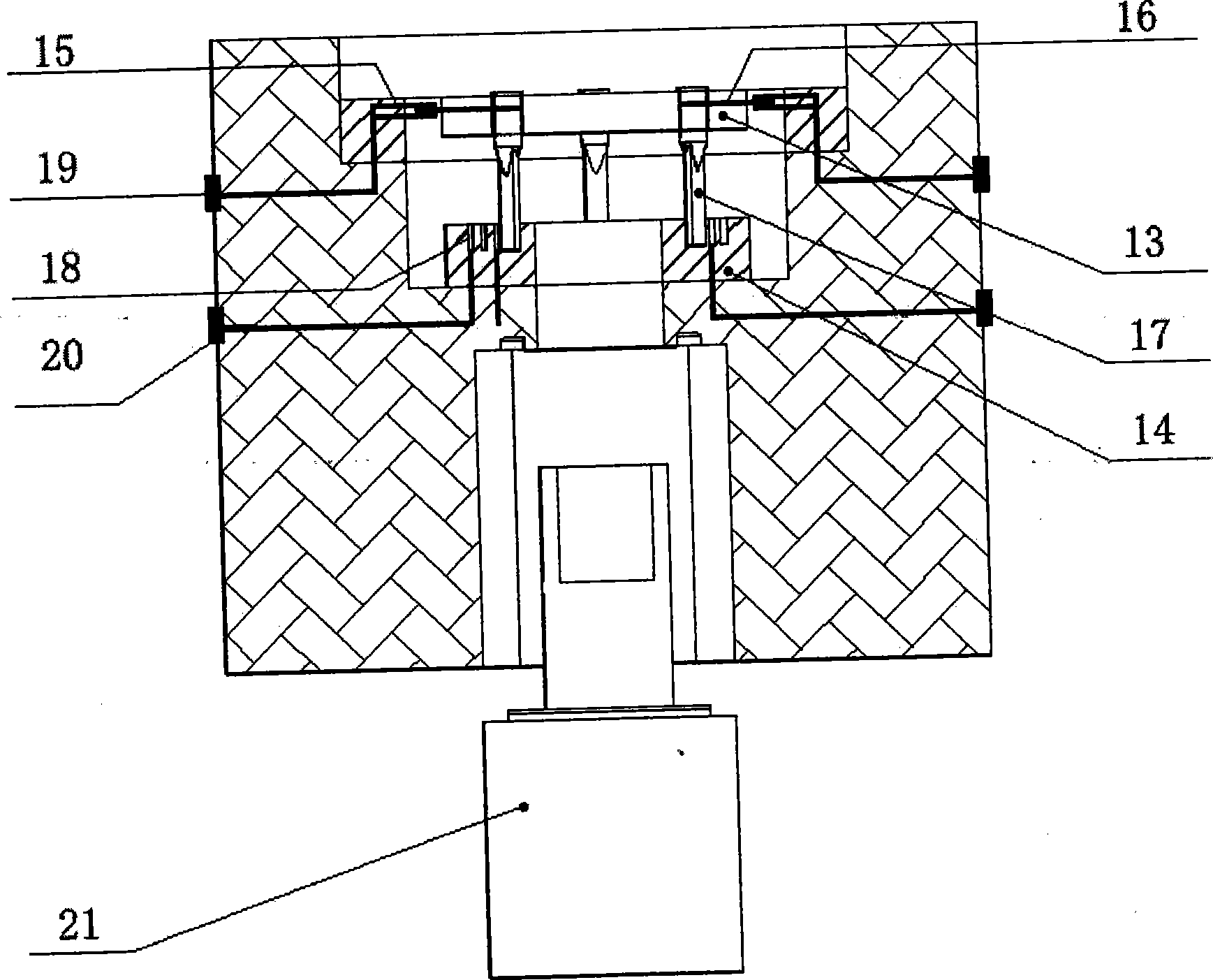

[0023] 4. Connect all the wires, including the power wire, the electric furnace wire between the controller and t...

Embodiment 2

[0026] Example 2: Installing a high-temperature and high-pressure reactor to measure the linear polarization resistance of the same electrode system in an unmanned state

[0027] 1. Connect the three working electrodes 12 to the wires at the bottom of the wire fixing bolts 8 and seal them with epoxy resin.

[0028] 2. Fix the wire fixing bolt 8 to the bottom of the reactor cover 7, and install the three working electrodes 12 on the electrode fixing mold 9 inside the reactor cavity 1, according to figure 2 Position shown is correct. At this time, the auxiliary electrode 11 and the reference electrode 10 are not installed.

[0029] 3. Install the cover body 7, and carefully place the cover body 7 on the kettle body according to the fixed position. When tightening the main nut, tighten it diagonally and symmetrically for several times gradually. Use even force to achieve a good seal.

[0030] 4. Connect all the wires, including the power wire, the electric furnace wire betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com