Construction method of pull rod expansion screw bolt post embedding wall lacing wire

A technology of expansion bolts and construction methods, which is applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of long processing period, lack of on-site processing conditions, and increased transportation volume, and achieve reliable installation quality, convenient inspection, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

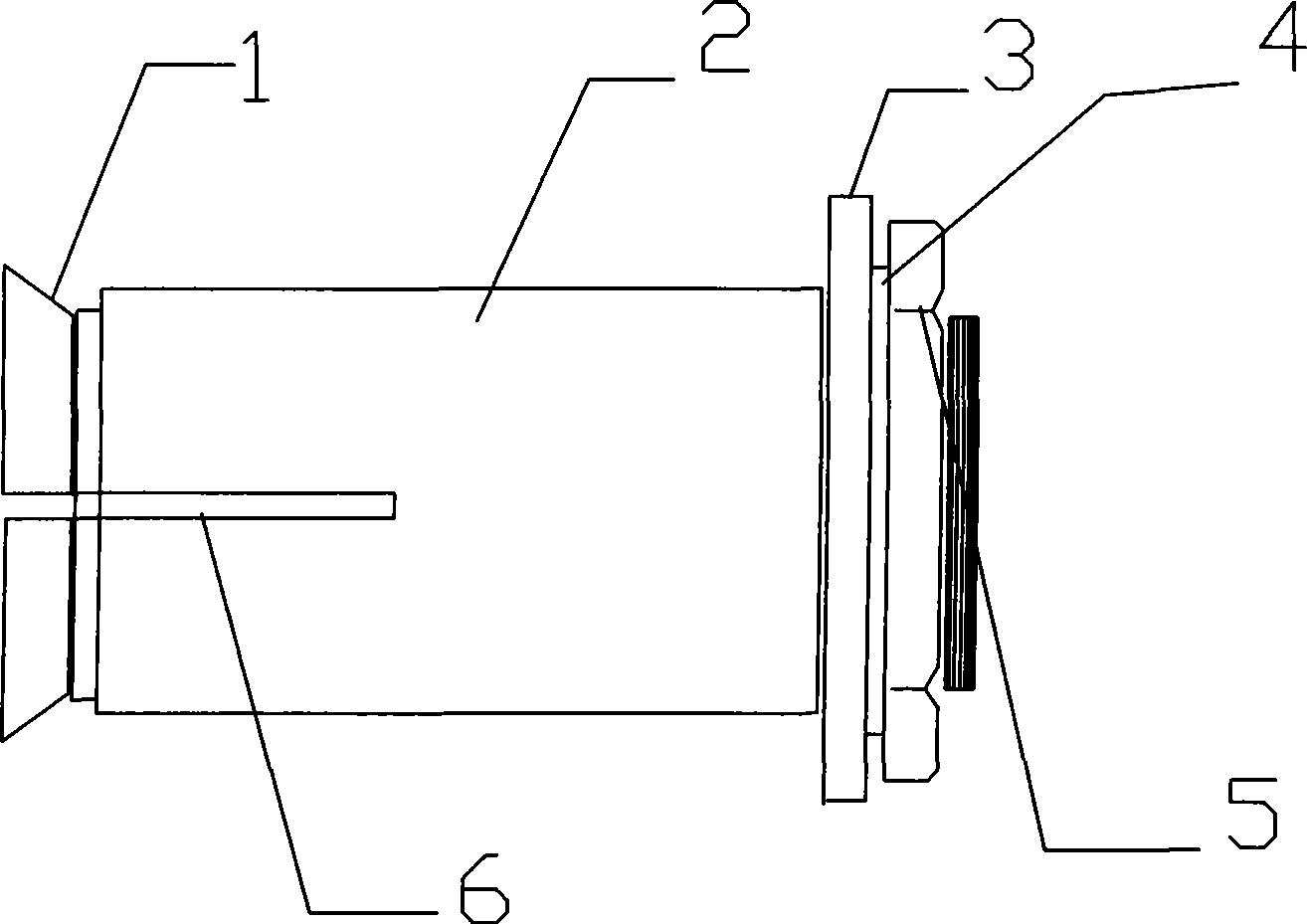

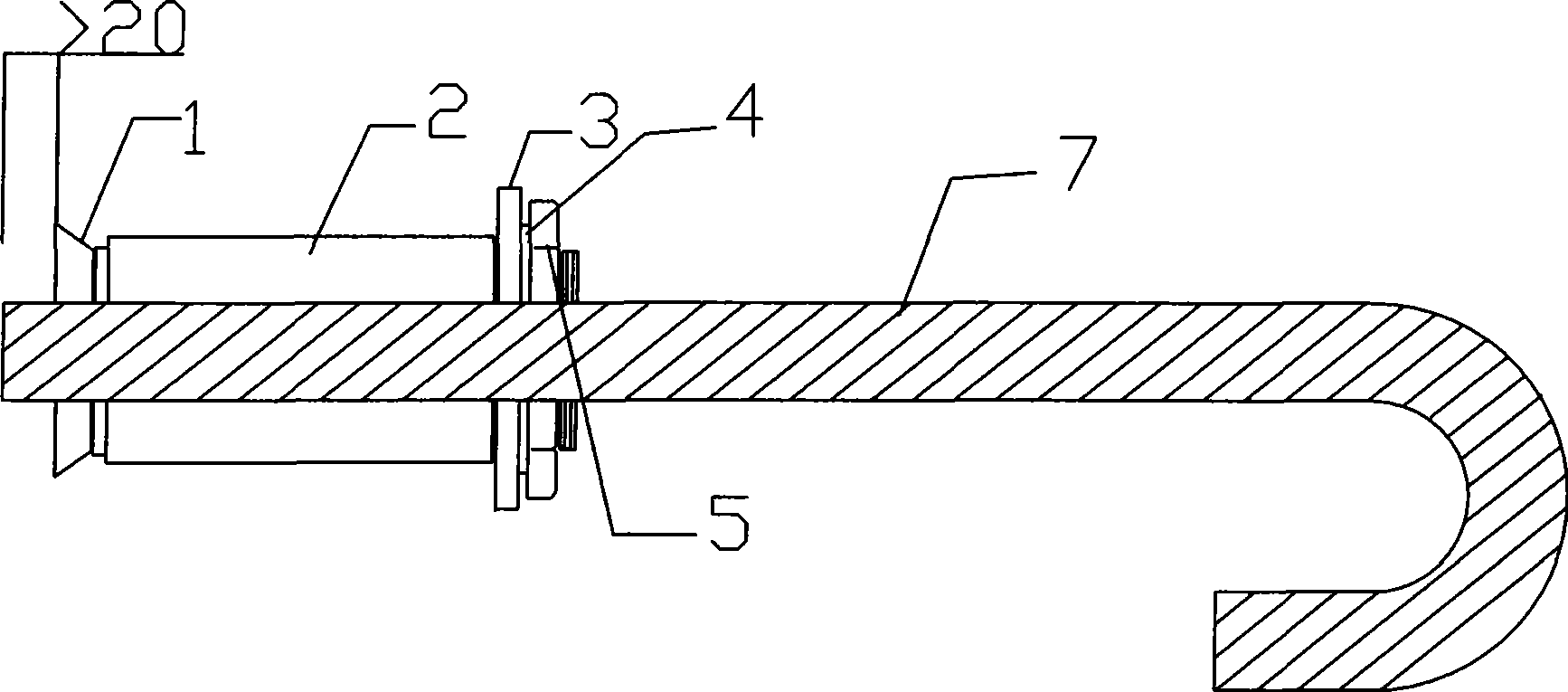

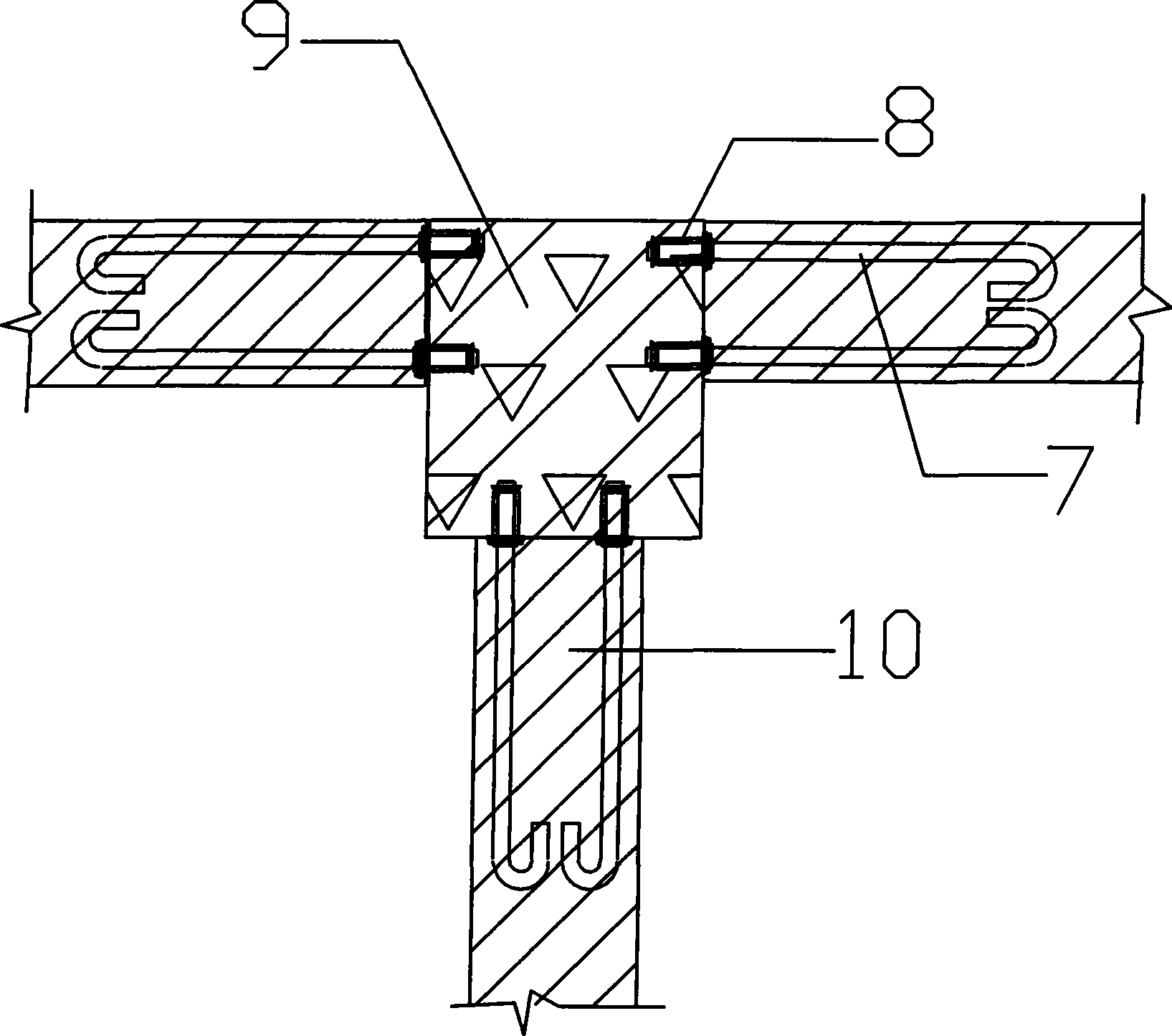

[0029] Use an impact drill or an electric hammer to drill a 65mm deep Φ16 hole on the concrete structural column 9, clean the scum and dust in the hole with a brush and an air bag, put the tie rod expansion bolt 8 into the hole, and then pull the Φ6 wall The tendon 7 is inserted into the countersunk head hollow bolt rod 1 of the tie rod expansion bolt 7 and the anchor end of the wall tie bar 7 protrudes ≥ 20mm. The torque nut 5 drives the countersunk head hollow bolt rod 1, and the force is applied through the spring washer 4 and the flat washer 3. It is transmitted to the expansion tube 2, and the expansion tube 2 compresses the gap 6 of the countersunk head hollow bolt rod 1, so that the thread of the inner cavity wall of the countersunk head hollow bolt rod 1 and the wall tie bar 7 are tightly hugged, and the nut 5 is continued to be twisted Drive the countersunk head of the countersunk head hollow bolt rod 1 to expand the expansion tube 2 and the concrete structure column 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com