Equipment with printing drive function and method for implementing printing drive

A printing drive and equipment technology, applied in the field of recorder drive, can solve the problems of high software overhead of upper computer and lower computer, complicated data transmission processing process, difficulty in ensuring real-time printing, etc., and achieves low cost, reduced relevance, and difficulty reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

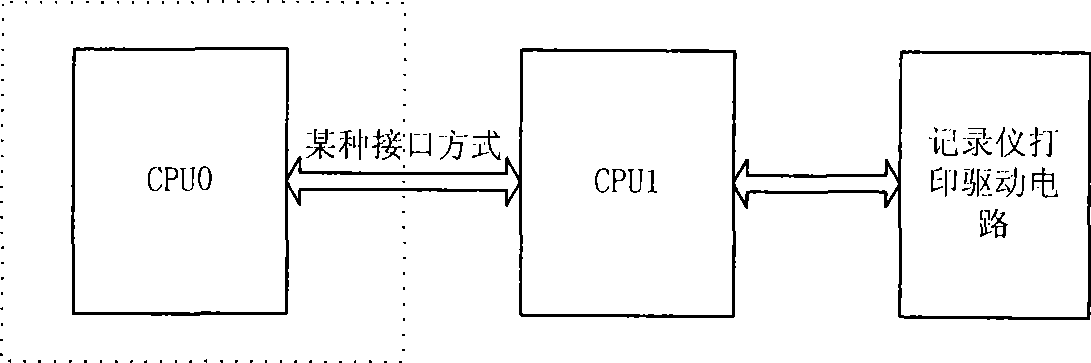

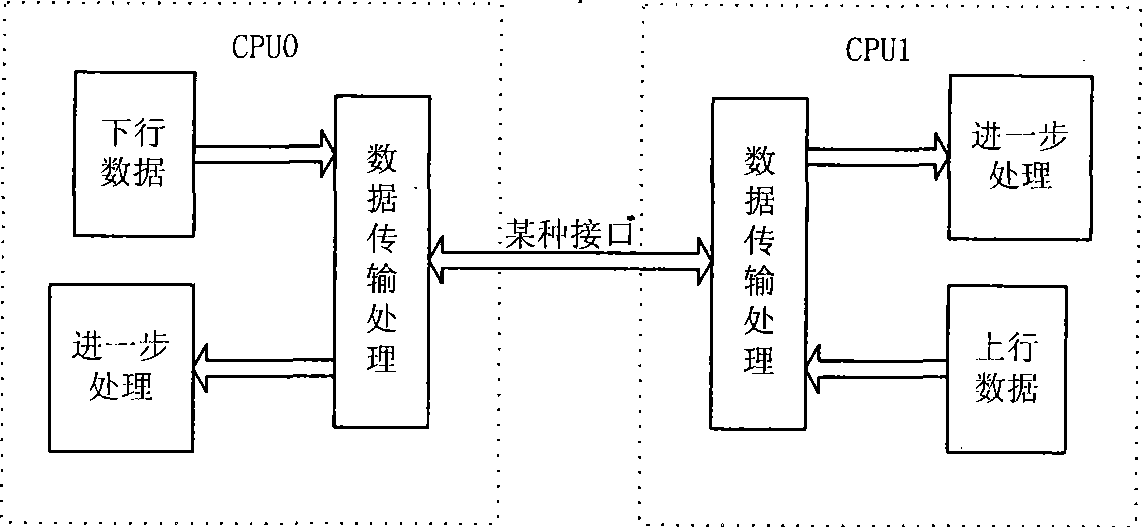

[0039] The present invention designs a realization scheme of the recorder drive circuit that can not only complete the main control but also realize the control of the recorder. Whether the scheme is applied to a bank self-service terminal or a medical electronic product, as long as it is a device with a printing function, it can A high-speed, high-performance print driver.

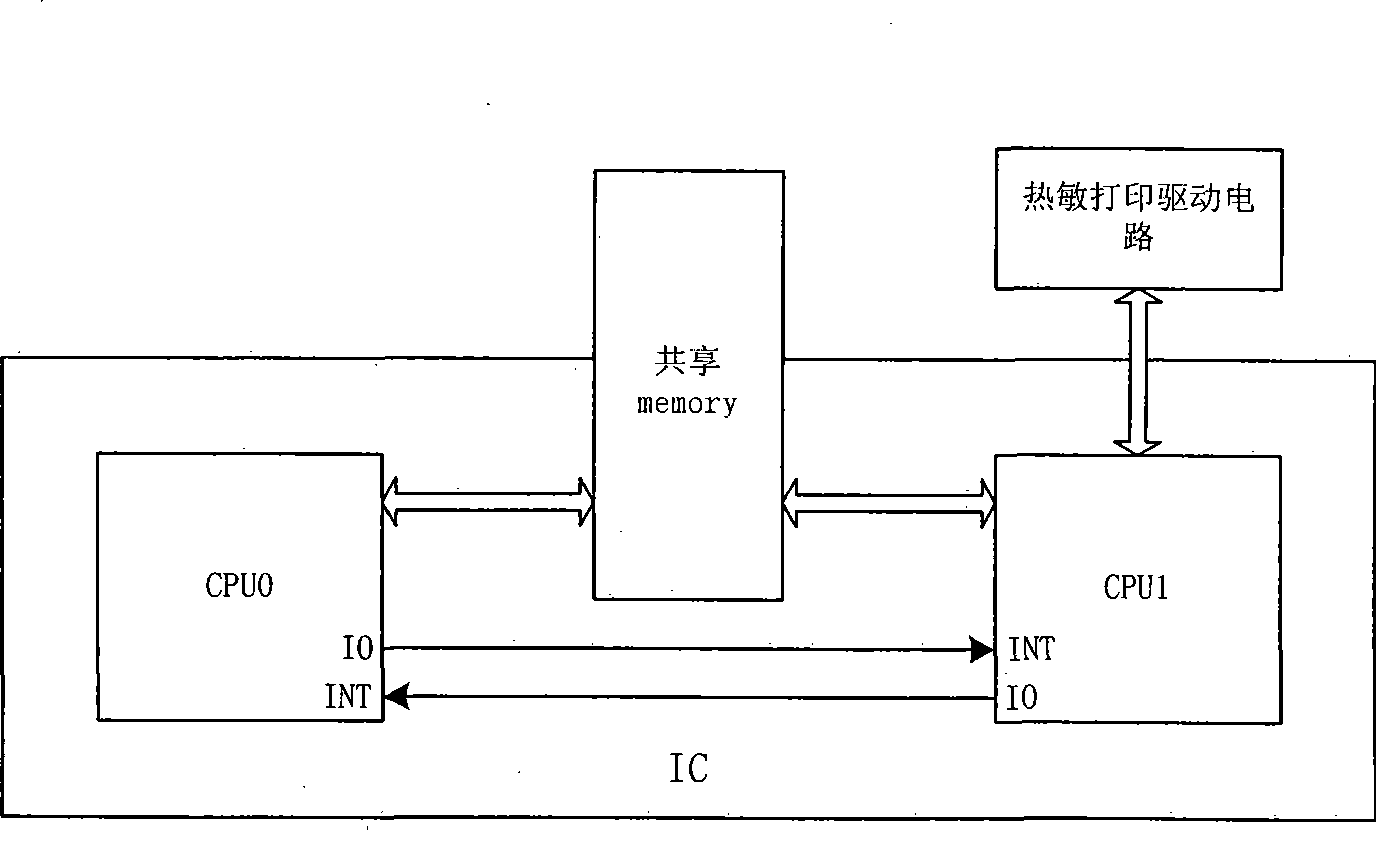

[0040] The equipment with printing function adopts a multi-core chip CPU that can realize multi-core function. Two or more CPU functions can be realized in this multi-core chip. Each CPU can work independently or cooperatively. , Each CPU can communicate through the shared memory. The present invention uses two CPUs in the multi-core chip to realize the main control of the equipment and the printing of the control recorder, such as image 3As shown, one of the cores is the main cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com