Control circuit for bistable state permanent magnet operating mechanism

A permanent magnet operating mechanism and control circuit technology, which is applied in circuits, relays, electric switches, etc., can solve problems such as poor breaking capacity, large power loss, and large operating noise, so as to reduce the number, reduce the failure rate, and reduce the opening The effect of the arc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

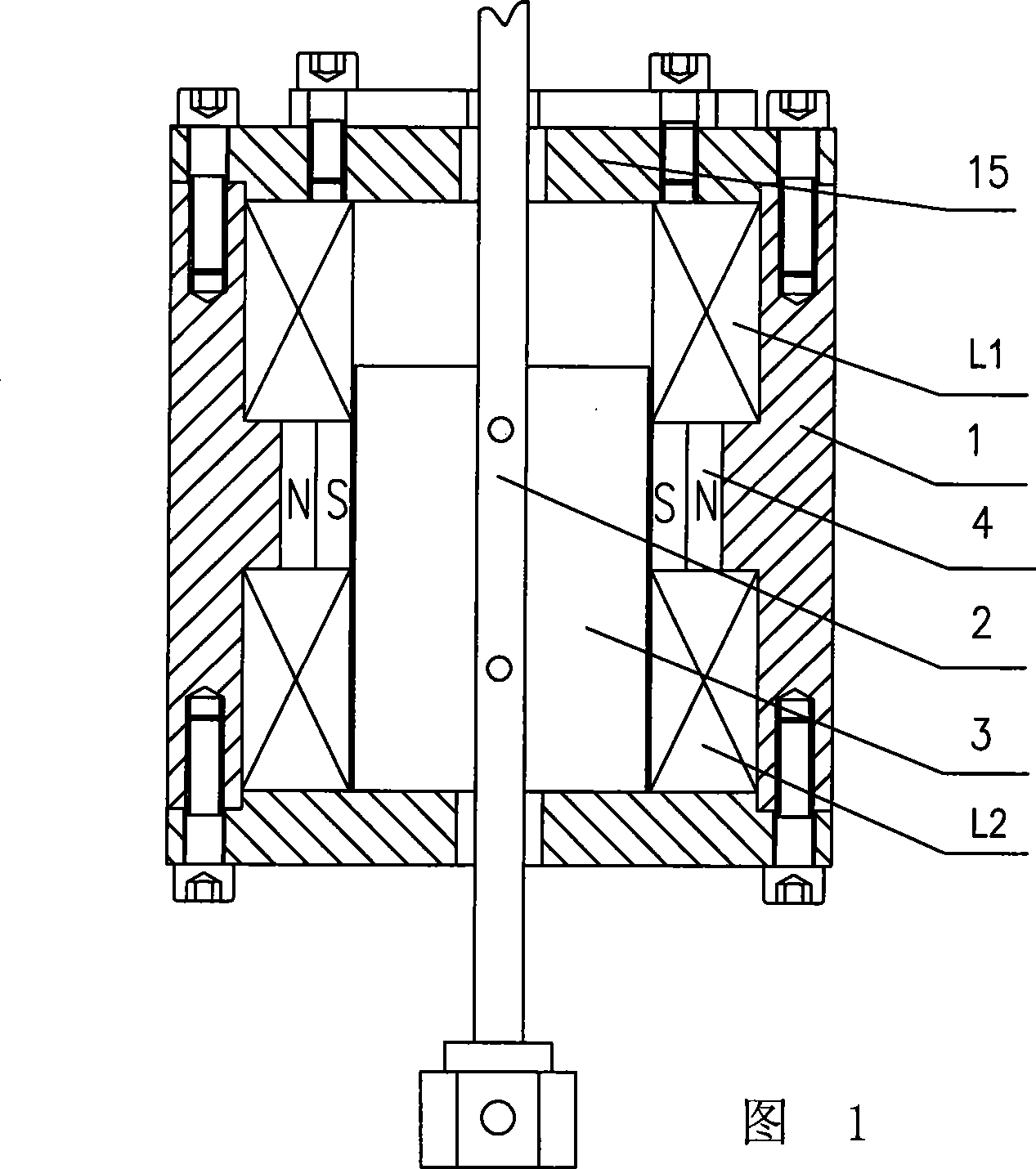

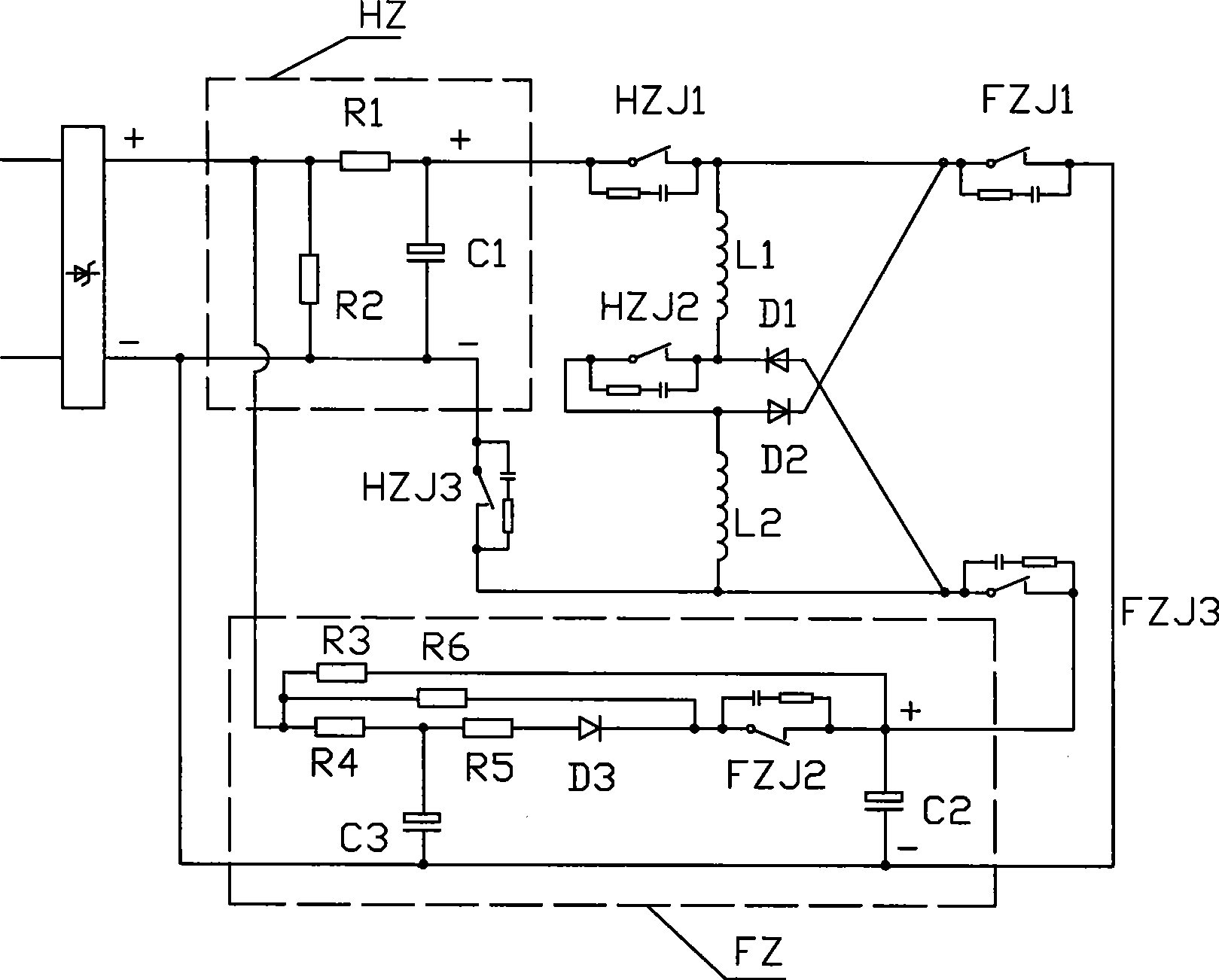

[0012] As shown in the drawings, the control circuit of a bistable permanent magnet operating mechanism according to the present invention includes a permanent magnet operating mechanism and a pulse signal control circuit connected to the pulse coil of the permanent magnet operating mechanism. As shown in Figure 1, the housing 1 of the permanent magnet operating mechanism is provided with an output shaft 2, the output shaft 2 protrudes through the end caps 15 at both ends of the housing 1, the front end is connected with the actuator through a connecting pin, and the rear end is fixedly connected with end cap9. The materials of the shell 1 and the end cover 15 are all ferrous which is easy to conduct magnetism. The contact part between the output shaft 2 and the shell 1 is fitted with an anti-magnetic bushing, and the middle section of the output shaft 2 located inside the shell 1 is fixedly installed with an iron core 3, and the outer side of the iron core 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com