Image display system and fabrication method thereof

A technology of image display and manufacturing method, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of long production time, high production cost, low production yield, etc., to reduce the number of photomasks and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Next, specific embodiments of the present invention and methods for making them will be described in detail. It can be appreciated, however, that the present invention provides many inventive concepts that can be implemented in a wide variety of fields of application. The examples used for illustration are merely illustrations of specific implementations utilizing the concepts of the present invention, and do not limit the scope of the present invention.

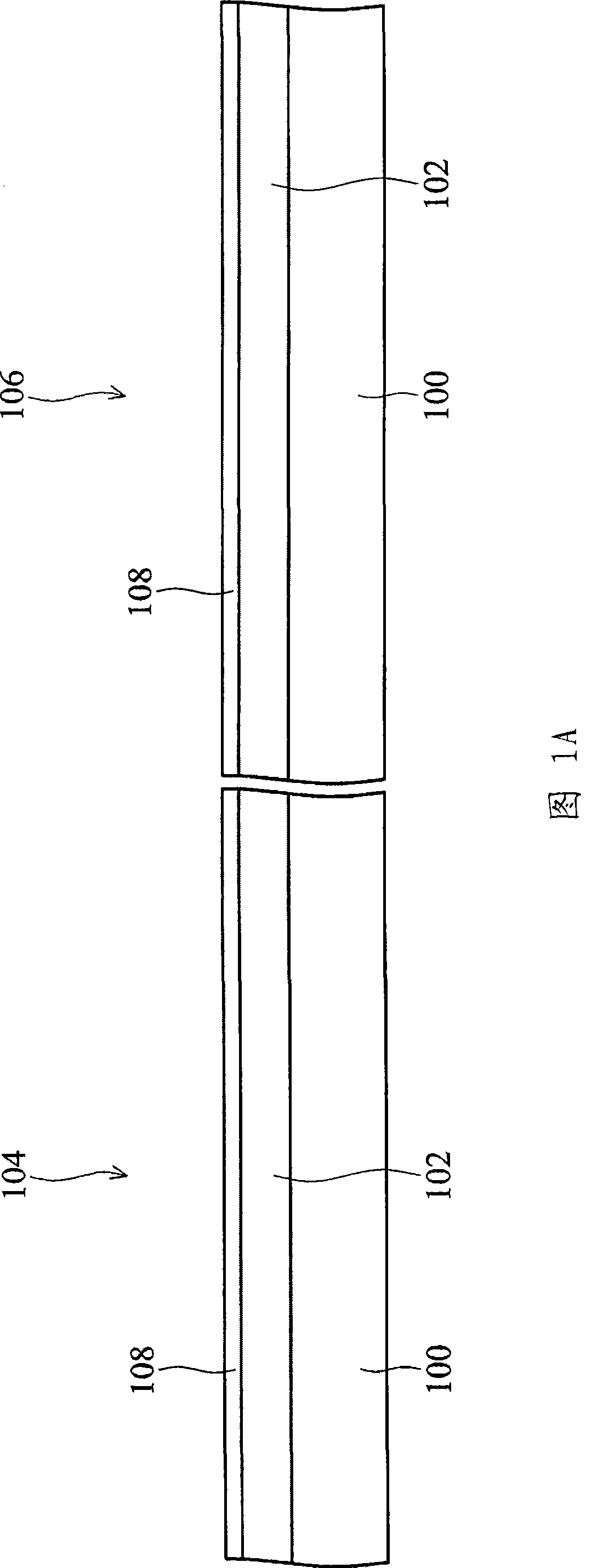

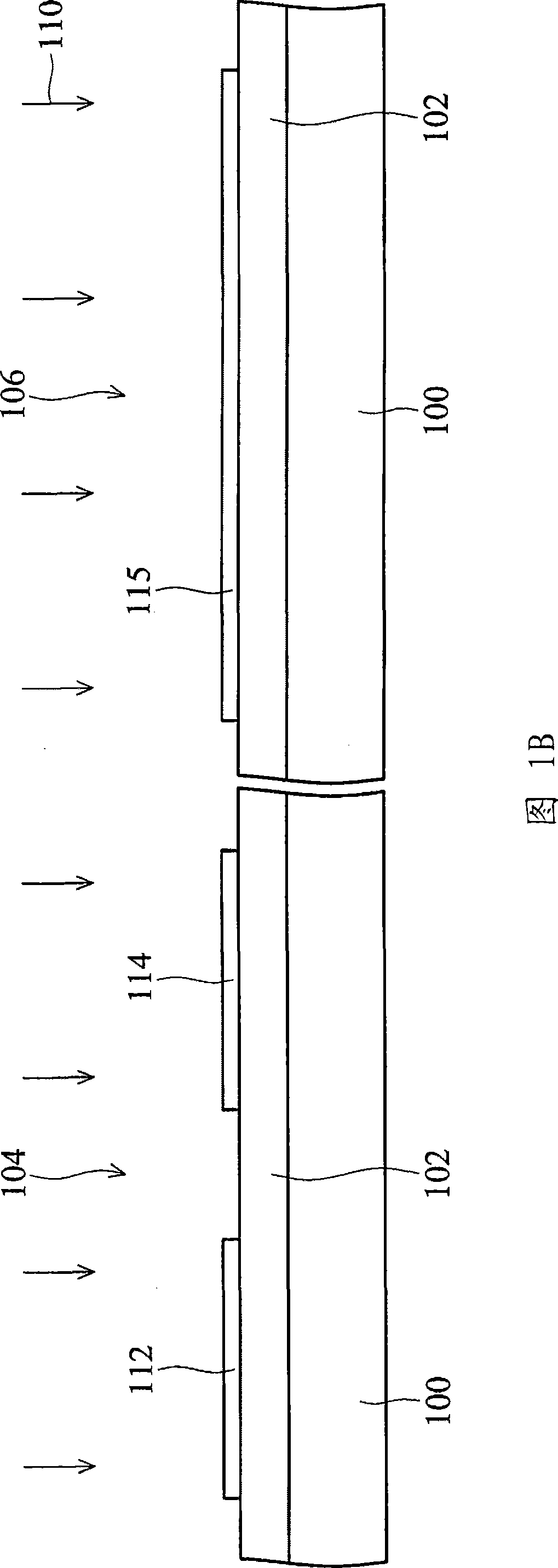

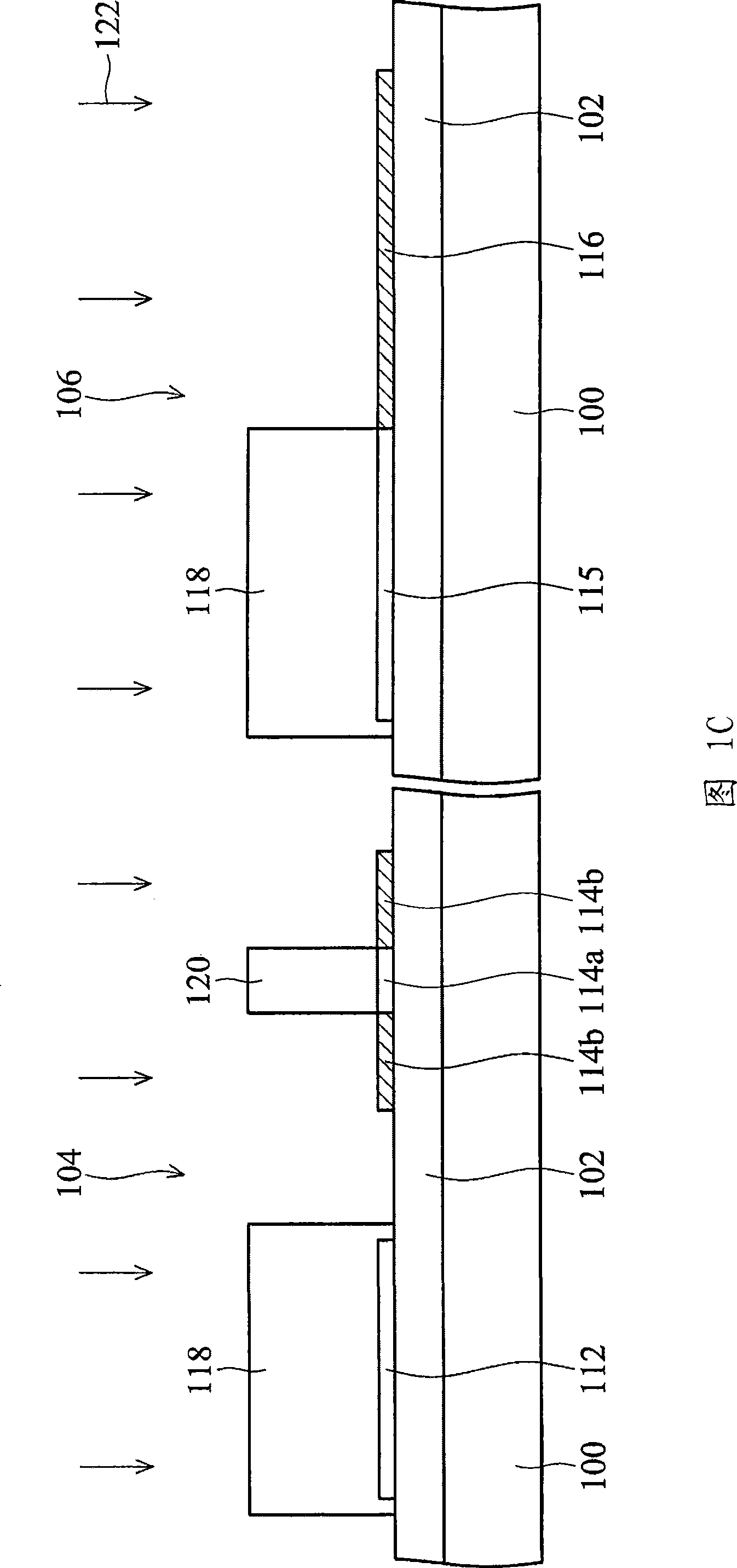

[0017] The present invention is illustrated by an embodiment of a low temperature polysilicon (LTPS) driving circuit and a thin film transistor (TFT). However, the concept of the invention can of course also be used to fabricate other integrated circuits. 1A-1H are cross-sectional views showing fabrication of a low-temperature polysilicon driving circuit and a thin film transistor according to a first embodiment of the present invention. 2A-2G are cross-sectional views showing fabrication of a low temperature polysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com