Red-hot coke receiving device

A technology of receiving device and coke, which is applied in the cooling of coke, coke oven, petroleum industry, etc., can solve the problems such as the decrease of the strength of the lifting frame mechanism, the difficulty of keeping the conveying bucket, and the increase of the turning radius.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

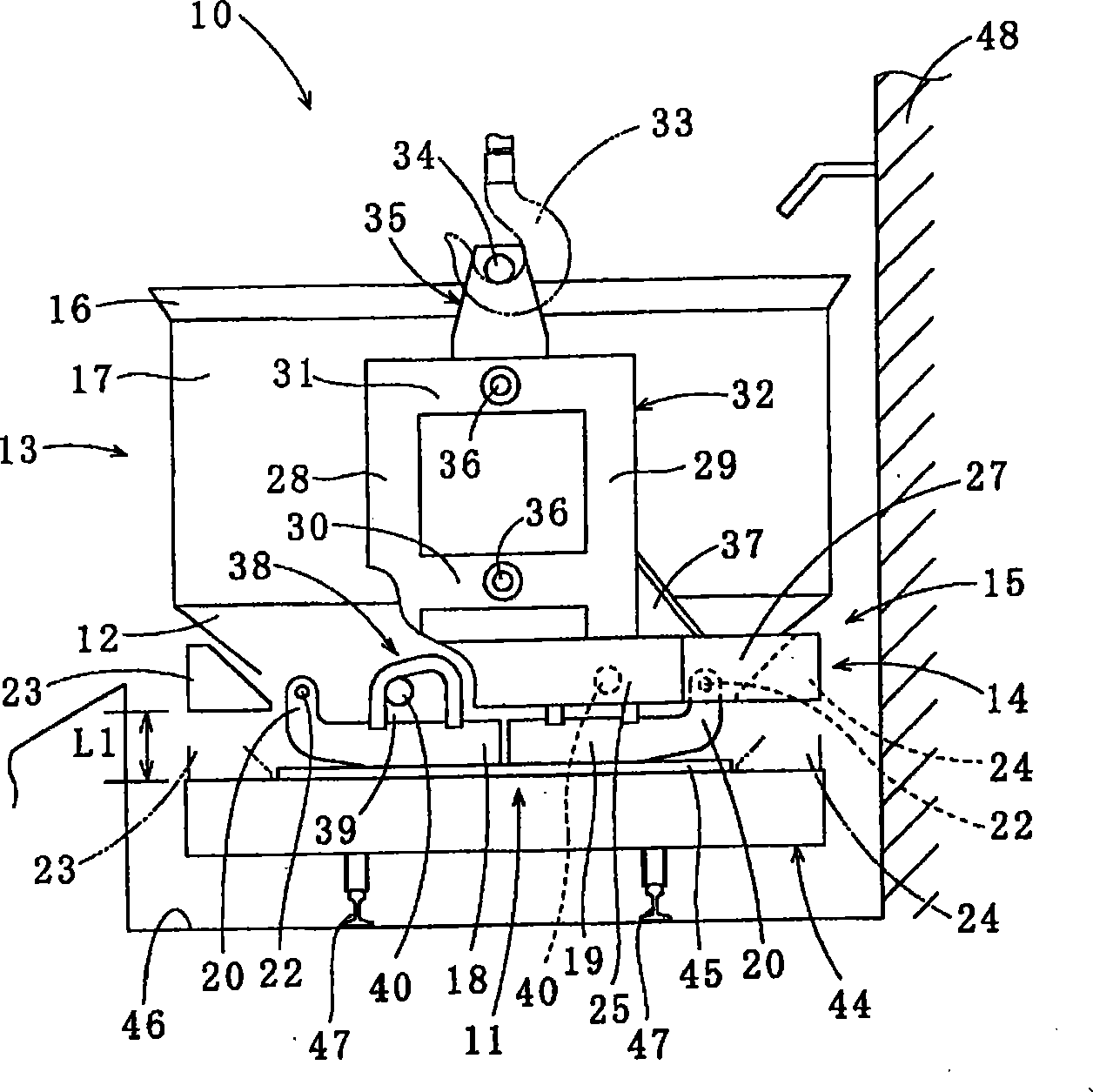

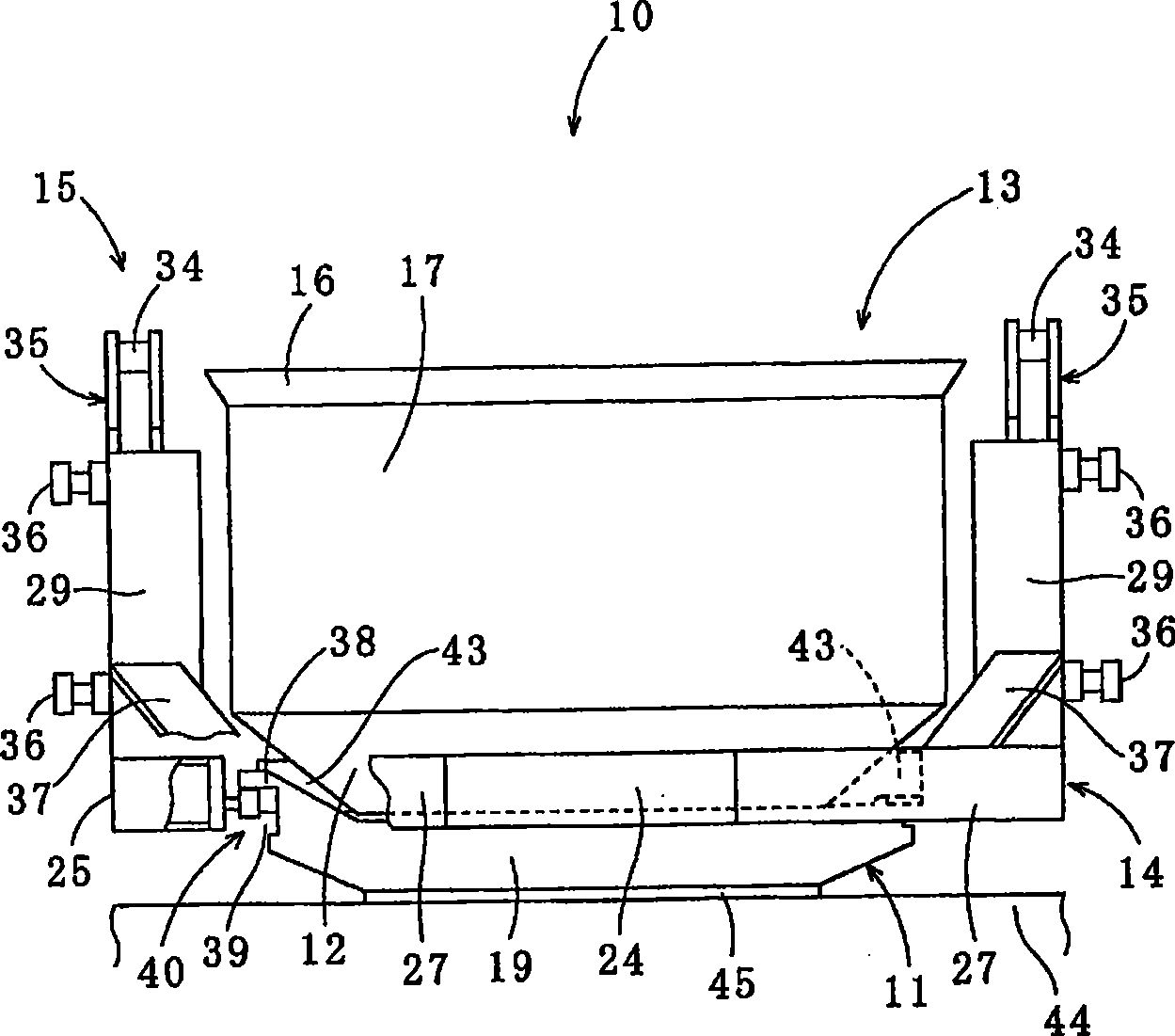

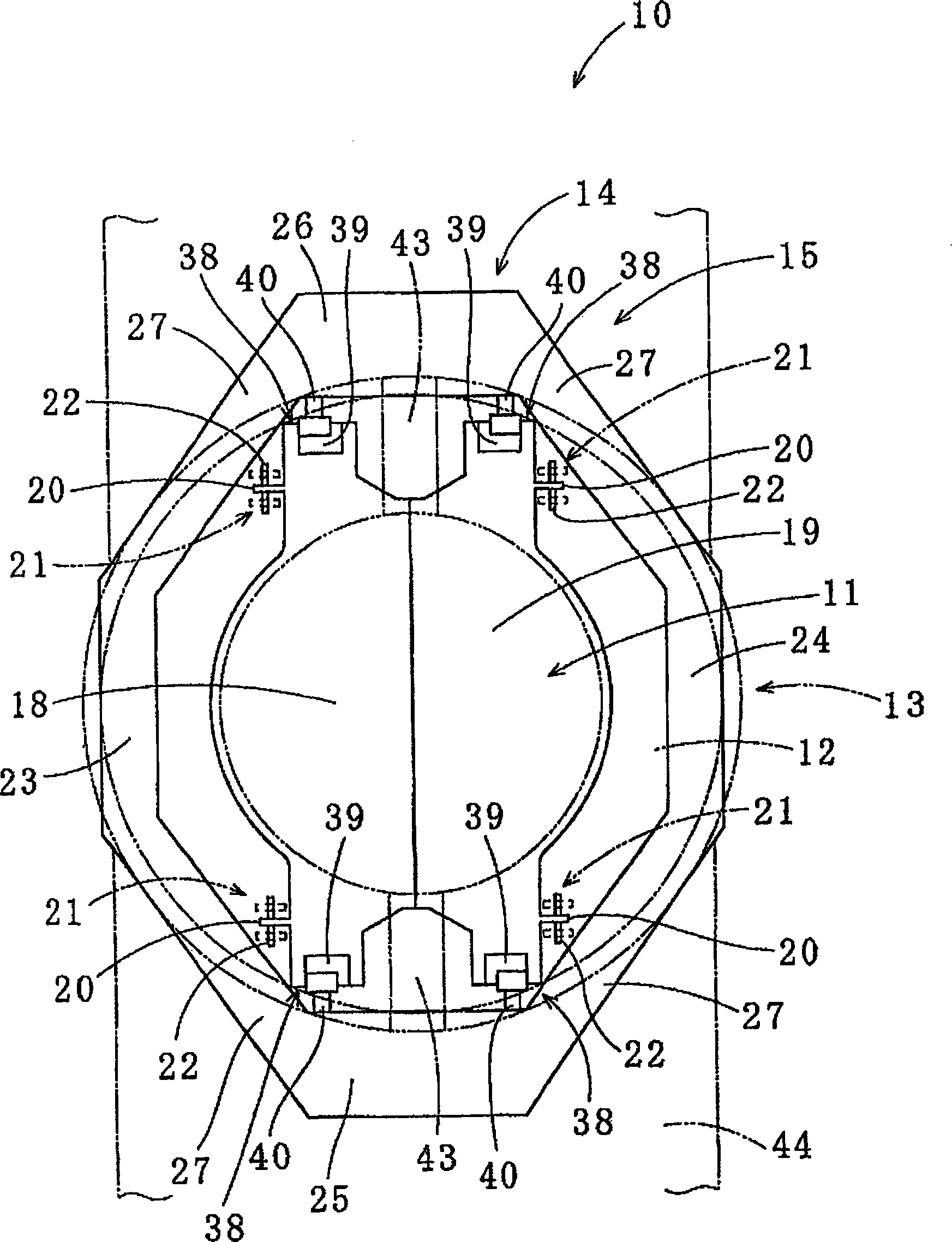

[0034] Hereinafter, specific embodiments of the present invention will be described with reference to the accompanying drawings for understanding of the present invention.

[0035] here, figure 1 It is a partially cutaway front view of a red-hot coke receiving device according to an embodiment of the present invention. figure 2 It is a partially cutaway side view of the red hot coke receiving device. image 3 It is the bottom view of the red hot coke receiving device. Figure 4 It is a front view showing the state when the red-hot coke receiving device starts to be lifted from the bucket trolley. Figure 5 It is a partially cutaway front view showing the state when the red-hot coke is discharged from the red-hot coke receiving device to the coke dry extinguishing equipment and the coke is loaded into the hopper. Figure 6 It is a partially cutaway side view showing the state when the red-hot coke is discharged from the red-hot coke receiving device to the coke dry-type fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com