Process for production of hydrocarbon oil and hydrocarbon oil

A manufacturing method and technology of hydrocarbon oil, applied in the direction of hydrocarbon oil cracking, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of insufficient octane number, high content, difficulty, etc., and achieve the effect of excellent low-temperature fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

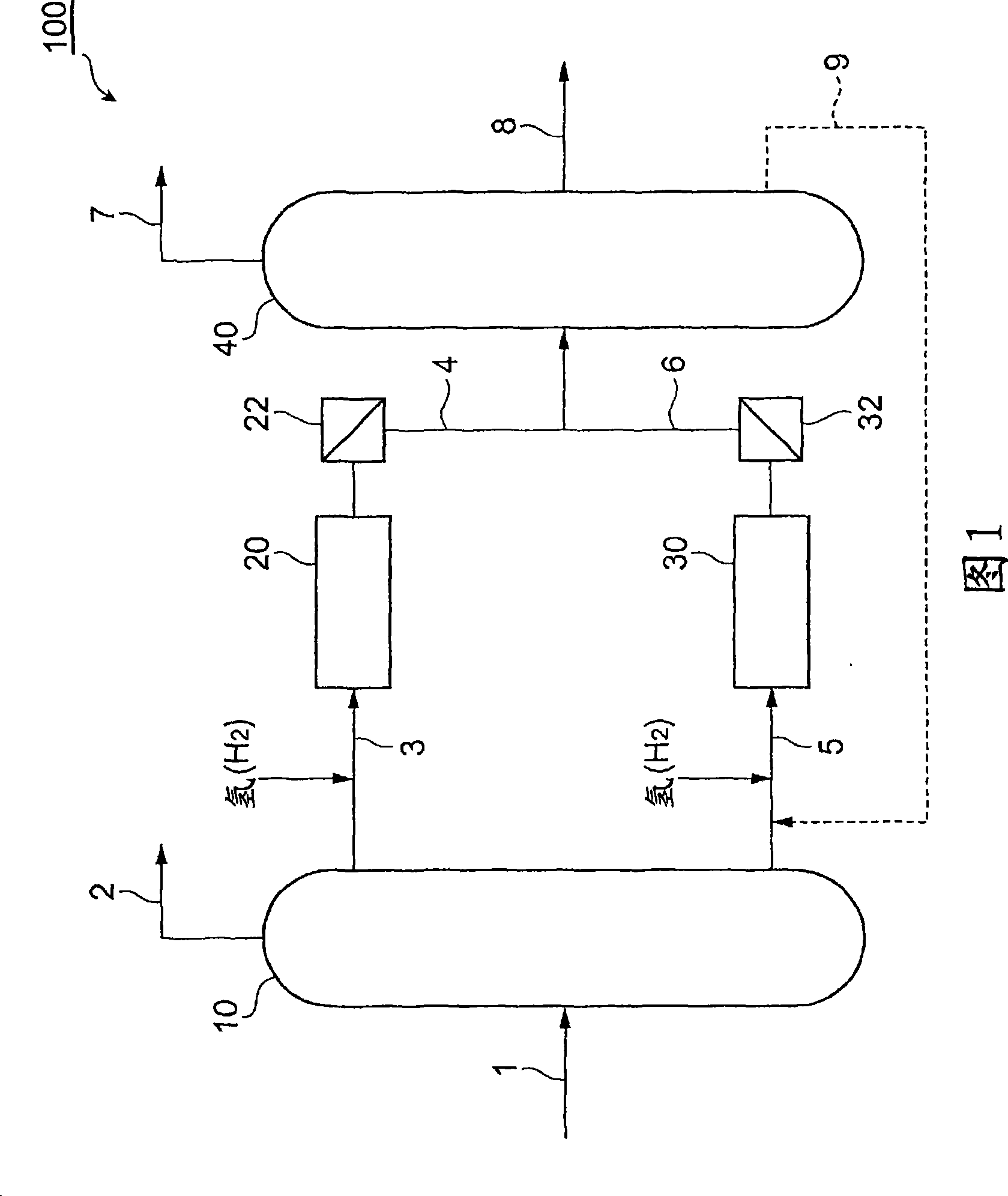

Image

Examples

Embodiment 1

(Fractional Distillation of FT Synthetic Oil)

The resulting oil obtained by the FT synthesis method (FT synthetic oil) (the content of hydrocarbons with a boiling point of 150°C or higher: 84% by mass, the content of hydrocarbons with a boiling point of 360°C or higher: 42% by mass, and the content of any of the hydrocarbons is expressed as FT The total amount of synthetic oil (based on the total amount of hydrocarbons with a carbon number of 5 or more) is separated in a distillation column into light fractions with a boiling point below 150°C, middle distillates with a boiling point of 150 to 350°C (hydrocarbons with a boiling point of 150 to 360°C) 100% by mass, 0% by mass of hydrocarbons with a boiling point of 350°C or higher, 19% by mass of hydrocarbons with a boiling point of 300 to 350°C, 0% by mass of hydrocarbons with a boiling point of 150°C or lower), and the heavy wax component of the bottom residue (corresponding to the fraction with a boiling point above 350°C). ...

Embodiment 2

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com