Method and device for removing acid in tail gas from reaction for producing 2-butyl acetate

A technology of sec-butyl acetate and tail gas, which is applied in the direction of separation method, carboxylate preparation, chemical instrument and method, etc., can solve the problems of high operating cost, small amount of acid gas, affecting economic benefits, etc., and achieves easy processing The effect of manufacturing, reducing production costs, and reasonable technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

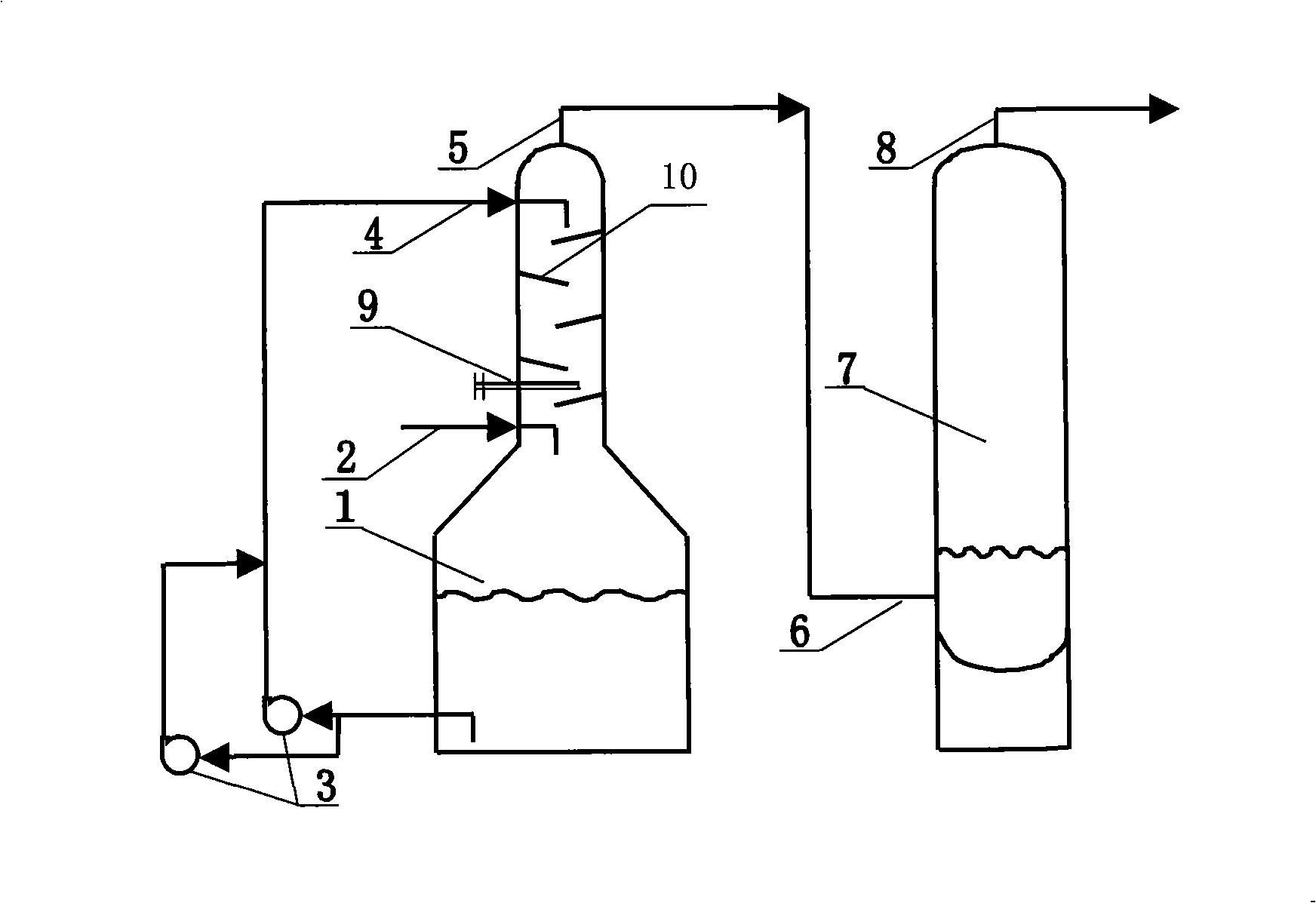

[0030] Take the tail gas treatment of a 30,000-ton / year sec-butyl acetate production line as an example. According to the above process flow and steps, a 10% circulating absorption sodium hydroxide solution is prepared. During the operation, the tail gas containing 99% concentration acetic acid is discharged at a rate of 5.9 t / h, the temperature control system of the deacidification tower is started, and two alkali The liquid circulation pump was started to run, and the accident treatment was completed after 10 minutes. The concentration of lye in sampling and analysis was 5.6%. The acetic acid content in the tail gas after deacidification could not be detected, and the quality of the tail gas met the requirements.

Embodiment 2

[0032] Take the tail gas treatment of a 30,000-ton / year sec-butyl acetate production line as an example. According to the above-mentioned technological process and steps, a 10% circulating absorption sodium hydroxide solution was prepared. During the operation, the tail gas containing 82ppm concentration acetic acid was discharged in an amount of 3.9t / h, and the small alkali liquor circulating pump of the deacidification tower was operated. After 10 minutes After the accident was dealt with, the concentration of lye in sampling and analysis was almost unchanged, the acetic acid content in the exhaust gas after deacidification could not be detected, and the quality of the exhaust gas met the requirements.

Embodiment 3

[0034] Take the tail gas treatment of a 30,000-ton / year sec-butyl acetate production line as an example. According to the above-mentioned technological process and steps, a 10% circulating absorption sodium hydroxide solution was prepared, and the tail gas containing 52ppm concentration acetic acid was discharged in an amount of 8.5t / h during the operation, and the small alkali liquor circulating pump of the deacidification tower was operated. After 15 minutes After the accident was dealt with, the concentration of lye in sampling and analysis was almost unchanged, the acetic acid content in the exhaust gas after deacidification could not be detected, and the quality of the exhaust gas met the requirements.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap