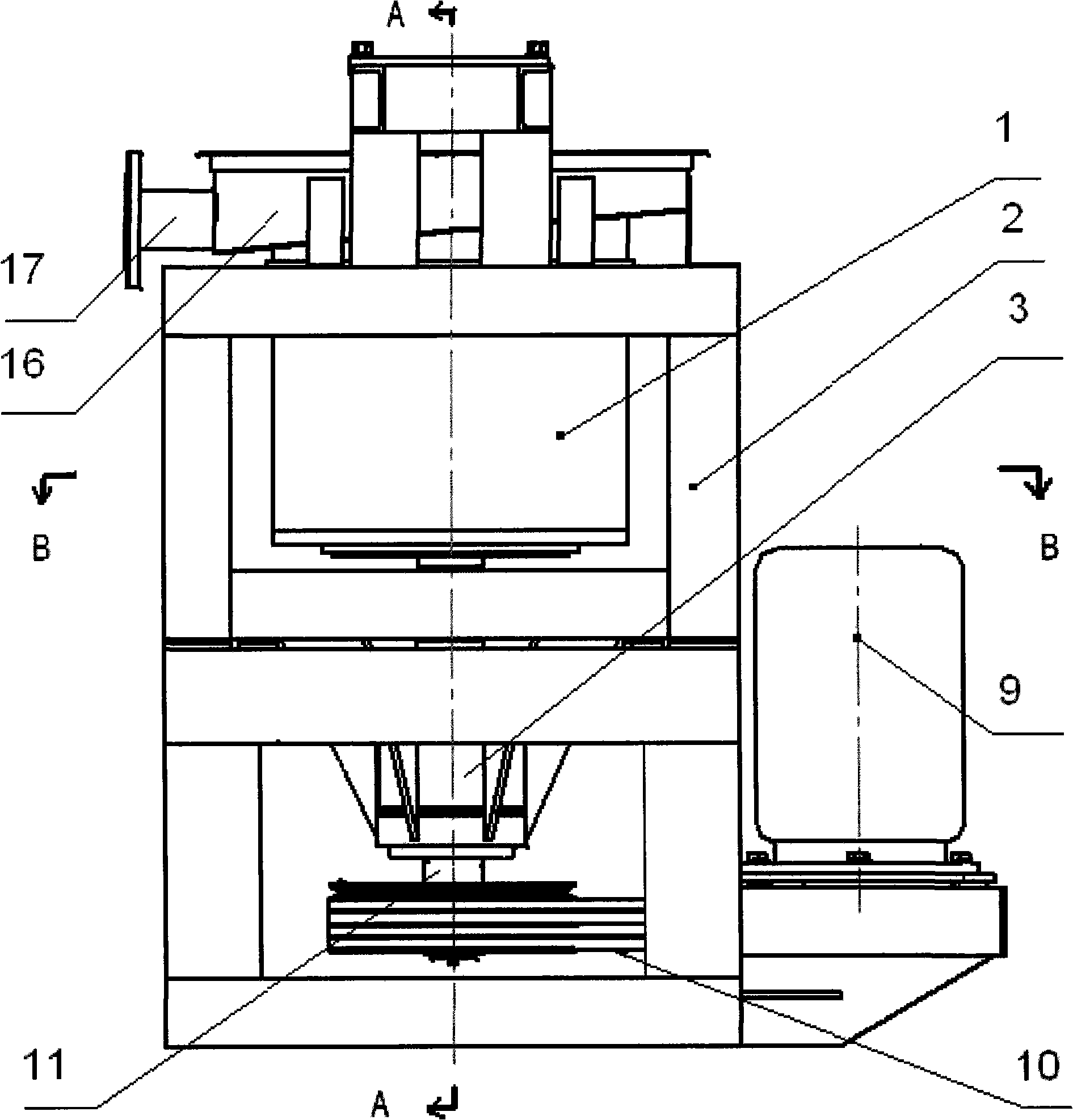

Vertical coaxial anticentripetal grinder

A centrifugal mill, coaxial technology, applied in grain processing and other directions, can solve the problems of large agitator wear, low production capacity, and restrict the development of large-scale equipment, and achieve the effect of uniform product particle size and reduction of grinding costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

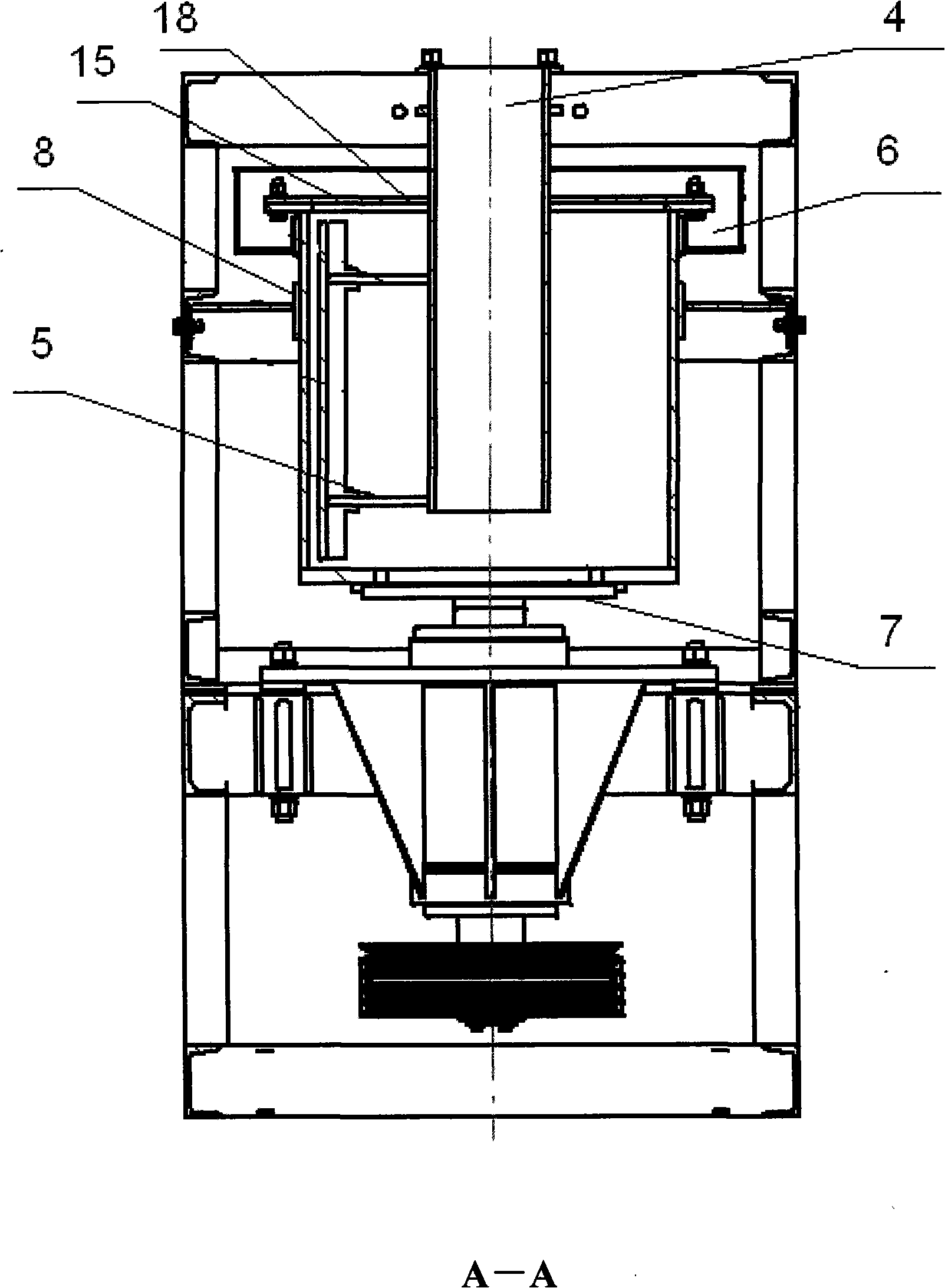

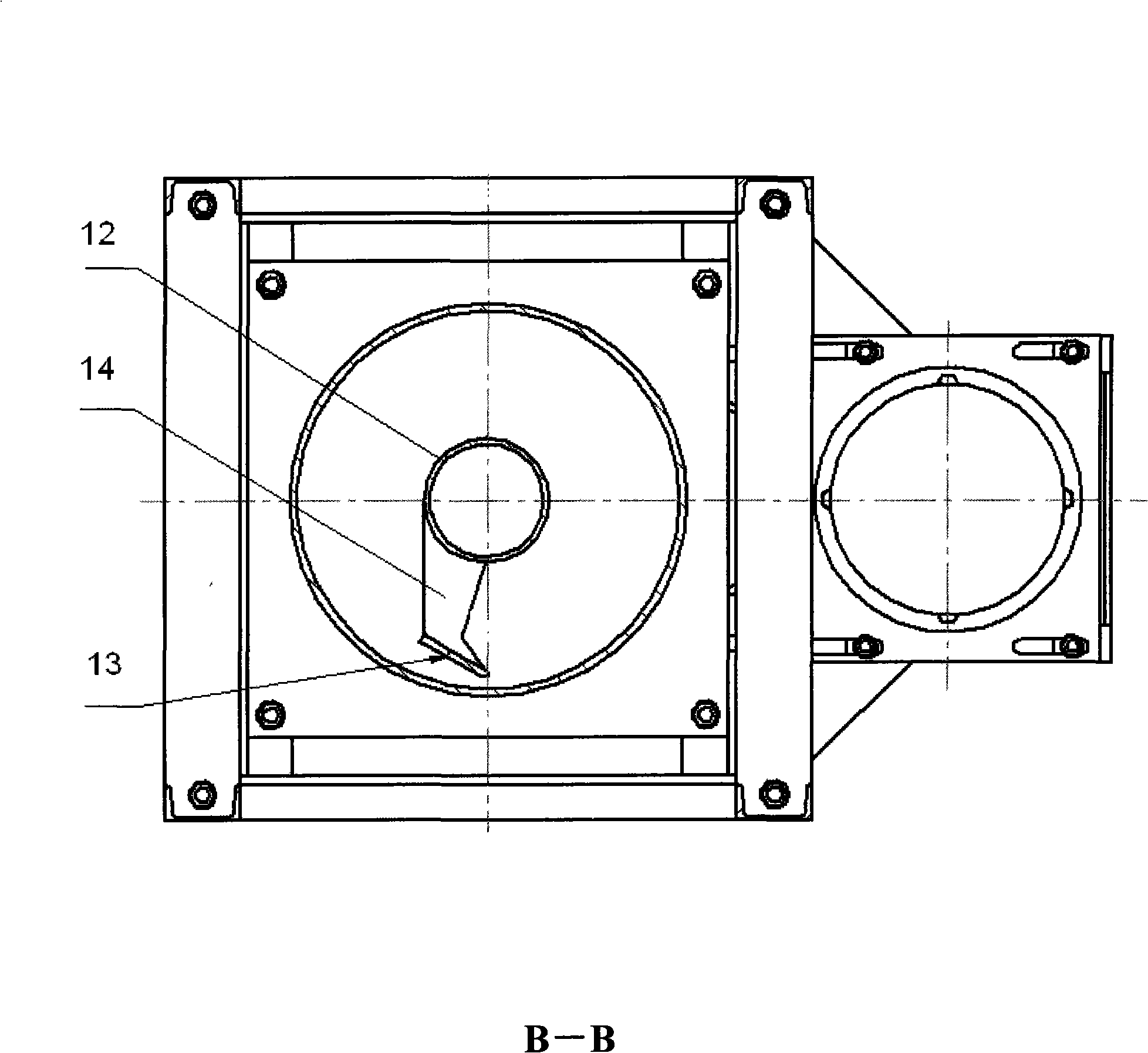

[0056] Embodiment 1: 1. Ore processing: pyrite, with a sulfur grade of about 16%, the largest particle size of the ore is 10mm, which belongs to soft ore, and the n determined by the test d 300r / min.

[0057] 2. Structural parameters of the mill: the diameter of the mill cylinder is 1000mm, the length is 1000mm, the power of the motor is 75kw, the transmission mechanism is belt drive, the length of the guide plate is 900mm, the width is 150mm, the interval between the cylinder wall and the cylinder wall is 30mm, the guide plate It is planar with an inclination angle of 50 degrees.

[0058] 3. Grinding medium: self-grinding without adding medium.

[0059] 4. Operating parameters: The rotational speed of the mill is 350r / min, and the processing capacity is 4t~6t / h.

[0060] 5. Grinding effect: 90% of the mass percentage of the feed particle size is less than 5mm, and 60% of the mass percentage of the discharge particle size is less than 0.045mm.

Embodiment 2

[0061] Embodiment 2: 1, processing ore: magnetite, iron grade is about 40%, belongs to medium hard ore, the n that test determines d It is 200r / min.

[0062] 2. Structural parameters of the mill: the diameter of the mill cylinder is 1200mm, the length is 2000mm, the power of the motor is 160kw, the transmission mechanism is belt drive, the length of the guide plate is 1600mm, the width is 240mm, and the gap between the cylinder wall and the cylinder wall is 15mm. It is a curved plate with a curvature greater than that of the cylinder, and the inclination angle is 40 degrees.

[0063] 3. Grinding medium: steel ball, 3mm in diameter; the ore itself.

[0064] 4. Operating parameters: The rotational speed of the mill is 250r / min, and the processing capacity is 8t~12tkg / h.

[0065] 5. Grinding effect: 90% of the mass percentage of the feed particle size is less than 3mm, and 50% of the mass percentage of the discharge particle size is less than 0.037mm.

Embodiment 3

[0066] Embodiment 3: 1, processing ore: copper sulfide ore, copper grade 1%, belongs to medium hard ore, the n determined by the test d It is 200r / min.

[0067] 2. Structural parameters of the mill: the diameter of the mill cylinder is 1500mm, the length is 3000mm, the power of the motor is 210kw, the transmission mechanism is gear transmission, the length of the guide plate is 2100mm, the width is 375mm, and the interval between the cylinder wall and the cylinder wall is 40mm. It is a curved plate with a curvature greater than that of the cylinder, and the inclination angle is 70 degrees.

[0068] 3. Grinding medium: Add 8mm~3mm coarse-grained magnetite as the medium.

[0069] 4. Operating parameters: The rotational speed of the mill is 250r / min, and the processing capacity is 15t~20t / h.

[0070] 5. Grinding effect: 90% of the mass percentage of the feed particle size is less than 3mm, and 50% of the mass percentage of the discharge particle size is less than 0.045mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com