Automatic continuous vacuum packaging machine for primary lobes tea

A vacuum packaging machine, automatic technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of unsuitable tea vacuum packaging, unrealized automation and continuous, unsuitable for vacuuming, etc., to achieve reasonable structure and continuous Sexuality, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

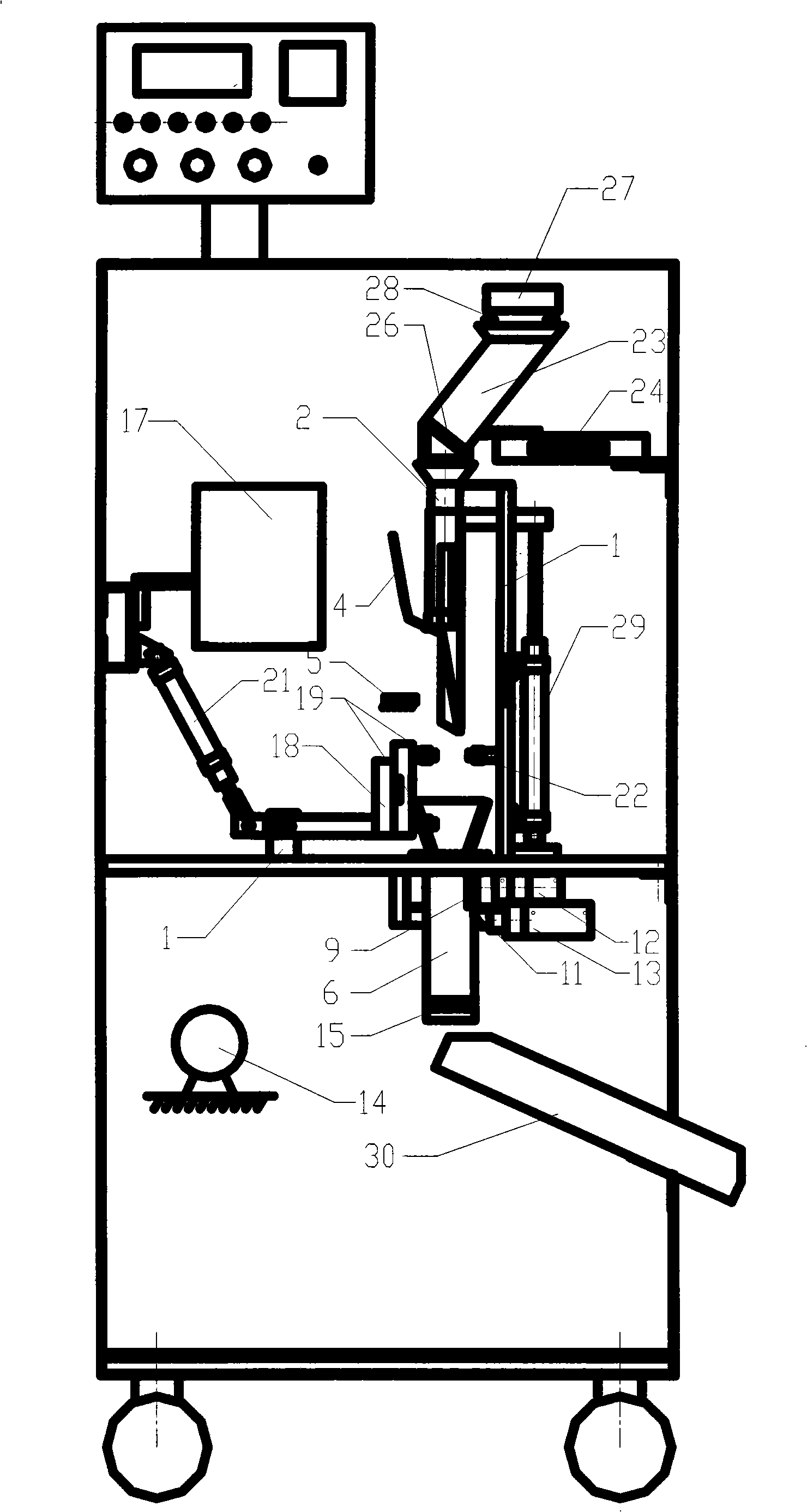

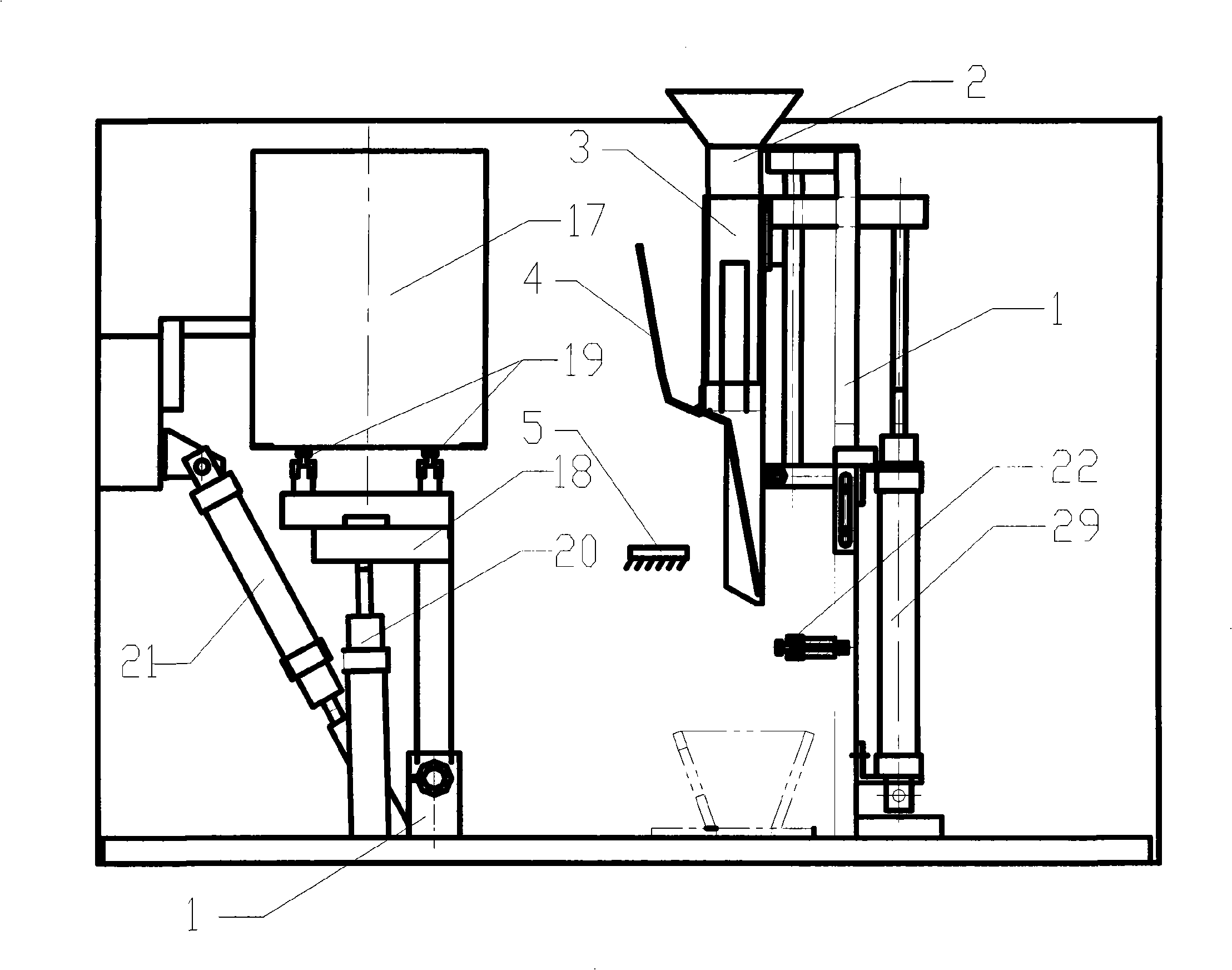

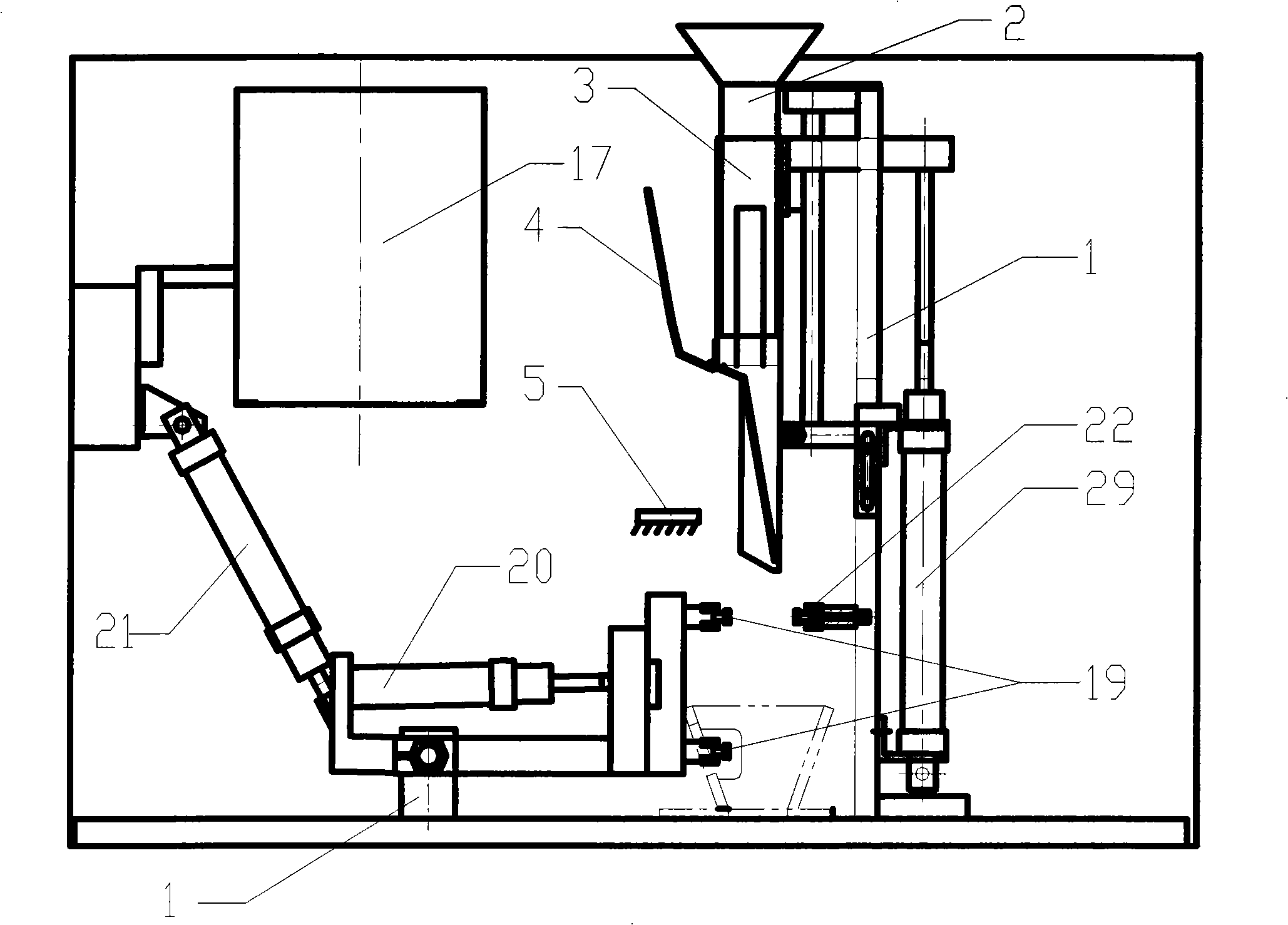

[0012] An automatic continuous vacuum packaging machine for raw leaf tea, comprising a receiving barrel 2 vertically installed on a frame 1, characterized in that: the lower part of the receiving barrel 2 is covered with a liftable discharge outer sleeve 3, the The lower part of the body of the discharge outer sleeve 3 is provided with a turning-shaped pressing arm 4, and the middle part of the turning-shaped pressing arm 4 is hinged at the opening 5 on the side wall of the discharging outer sleeve 3, and the lower turning extension arm extends downward. And seal the discharge passage of the discharge outer sleeve 3, the upper turning extension arm is positioned at the outside of the discharge outer sleeve 3, and the frame 1 is provided with a handle to block the turning when the discharge outer sleeve 3 descends. Press the arm 4 and make it rotate to open the retaining ring 5 of the discharge outer sleeve 3 passages. The lower side of the frame 1 is provided with a bagging mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com