Printing and proofing method for silk reactive dye cold dome

A reactive dye and printing technology, applied in the field of textile printing, can solve the problems of inconvenient proofing or color repair, low fixing rate, long cold stack printing time, etc., so as to shorten the proofing time and improve the fixing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

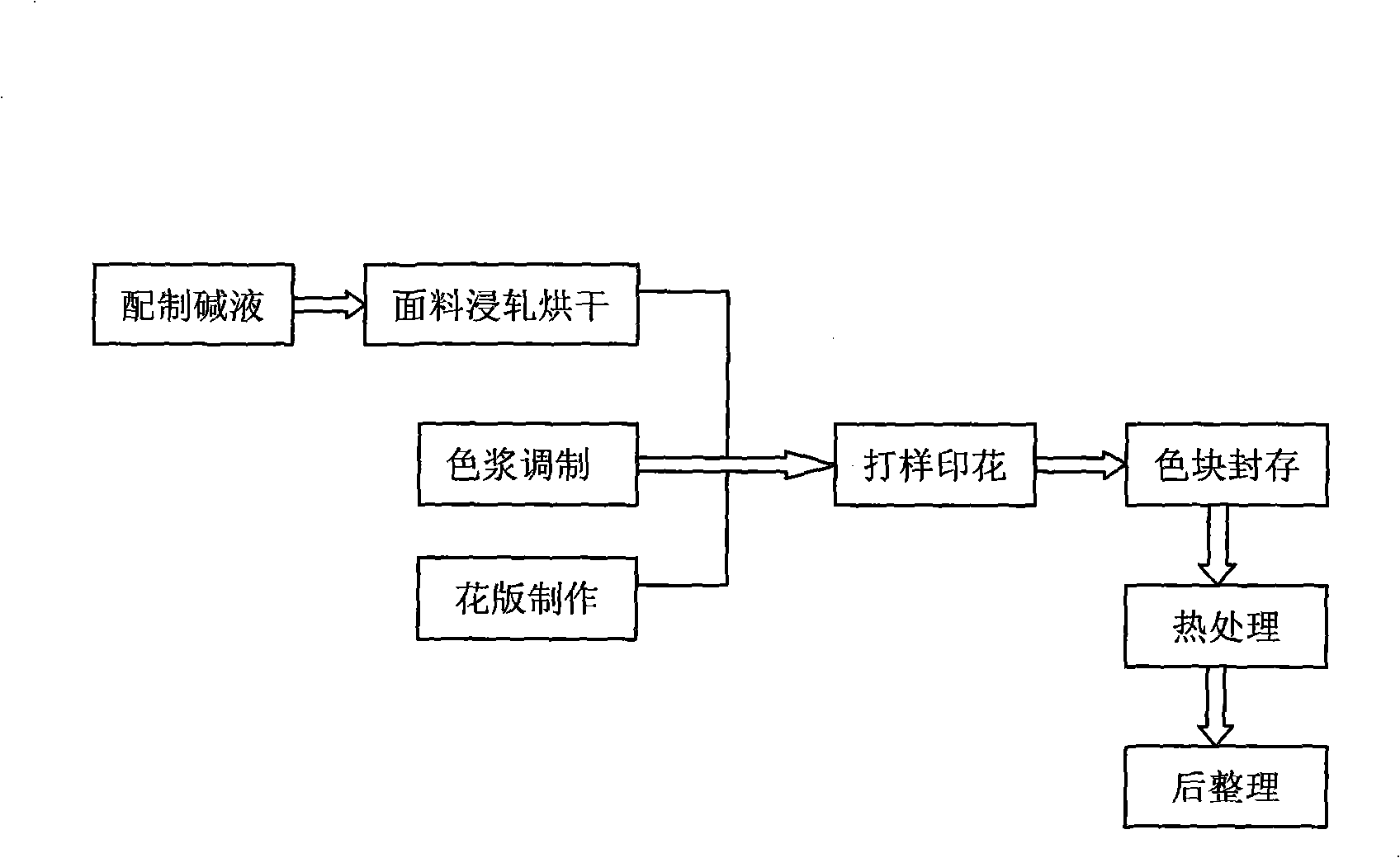

[0015] The process of the embodiment of the present invention silk reactive dyestuff cold batch printing proofing method is as follows figure 1 As shown, the main steps include preparation before printing, proof printing, color block sealing, heat treatment, and finishing. The pre-printing preparation steps include three steps that need to be completed before proofing and printing, but the sequence is not limited (that is, they can be completed simultaneously or successively): fabric preparation; color paste preparation; pattern making. The preparation of the fabric includes two steps: preparing lye; padding the fabric with lye and drying.

[0016] To prepare lye:

[0017] There are two ways to prepare lye, including:

[0018] Formula 1: Sodium hydroxide 2-4g / l, sodium carbonate 30-40g / l, the rest is water.

[0019] The formulation uses NaOH / Na 2 CO 3 combination. The printing uniformity of this combination is even without NaOH / Na 2 SiO 3 The combination is good, but u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com