Shell type heat exchanger for one third sector shaped helical baffle plate

A shell-and-tube heat exchanger and helical baffle technology, which can be used in heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as difficulty in marking and positioning and affecting the popularization and application of baffles. , to achieve the effect of convenient design, improved strength conditions, and reduced layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

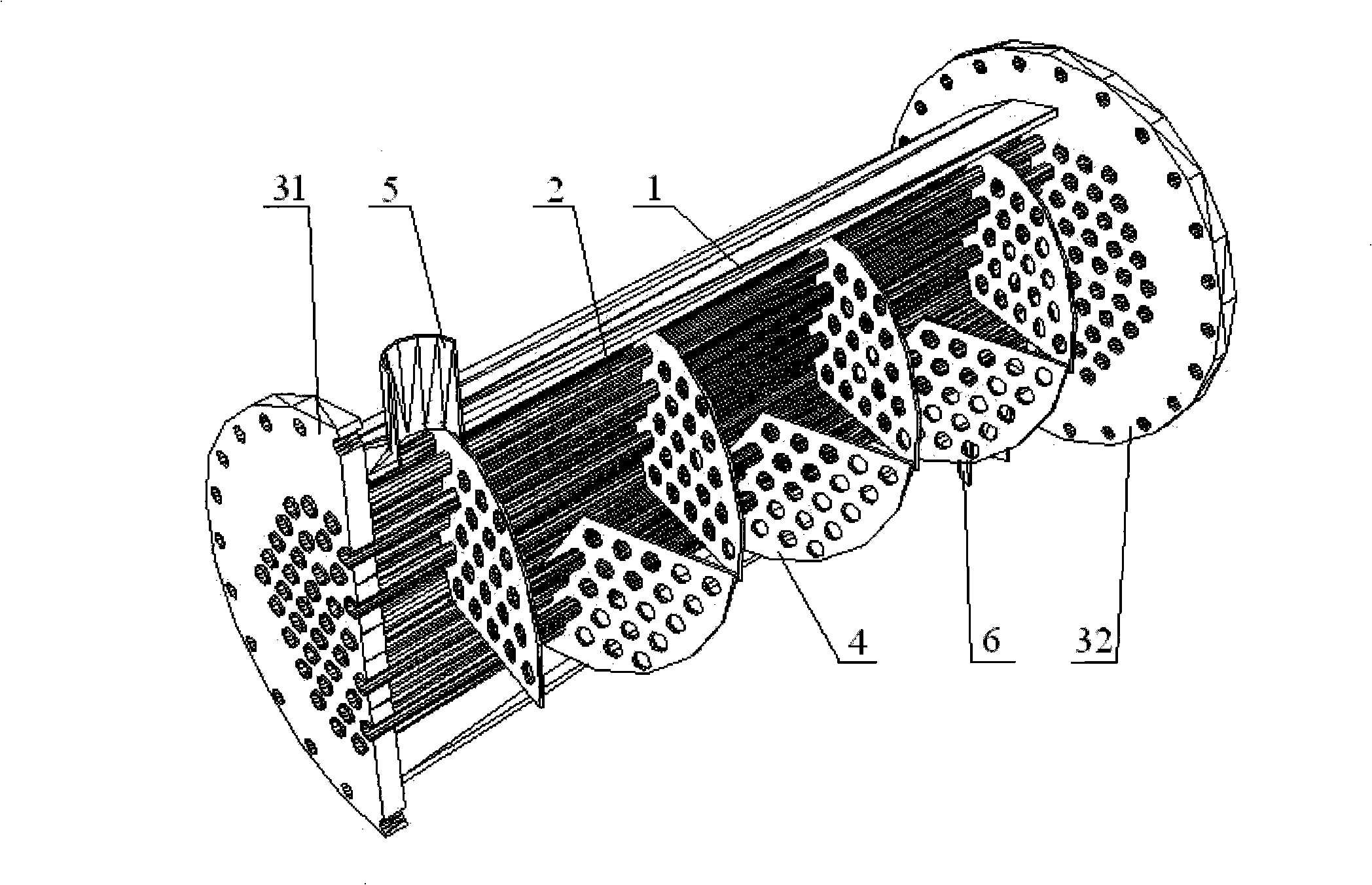

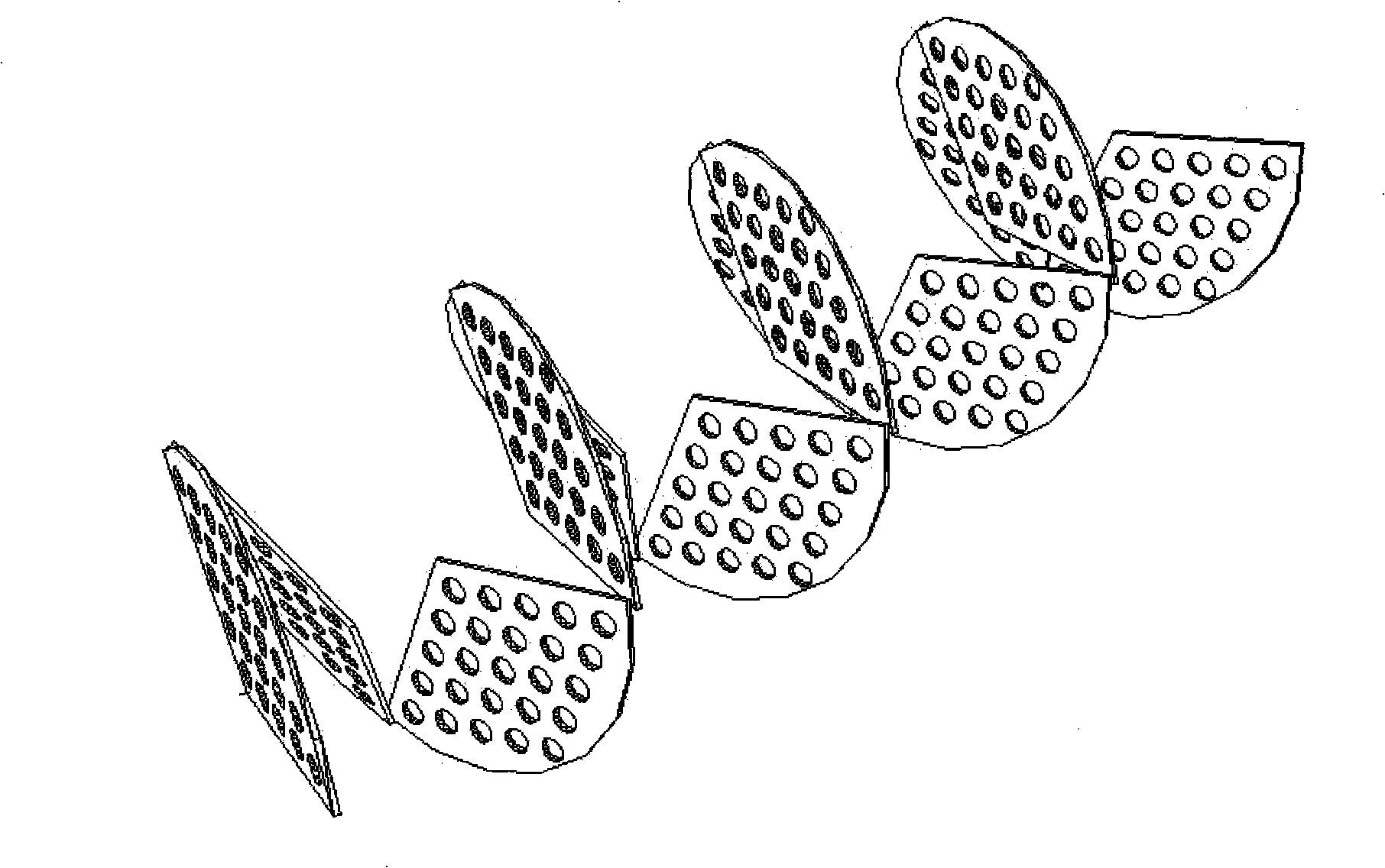

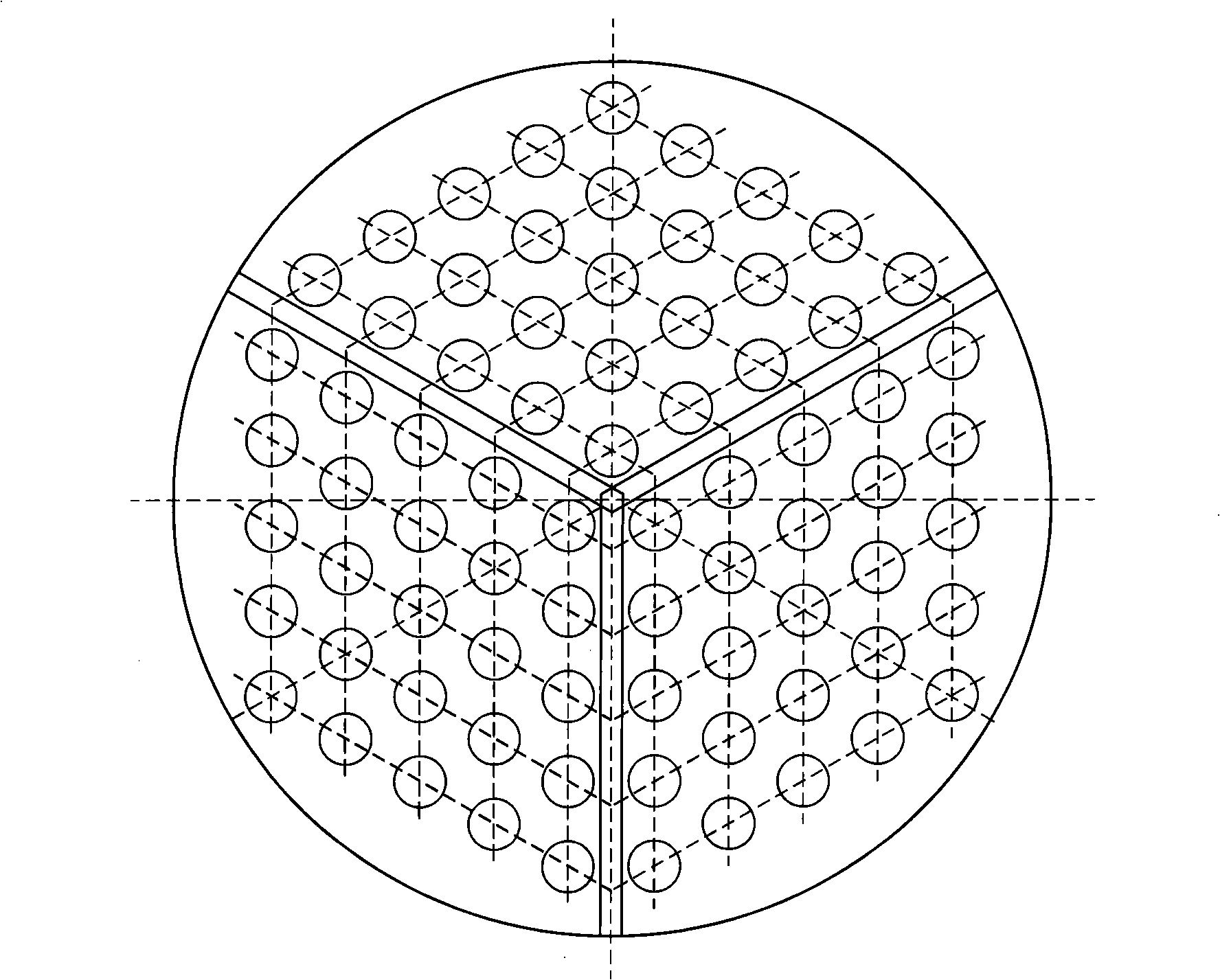

[0020] Example: such as Figure 1-6 As shown, the present invention includes a cylindrical shell 1, a tube bundle 2, a left tube plate 31, a right tube plate 32, a fluid inlet joint 5, a fluid outlet joint 6, and the left tube plate 31 and the right tube plate 32 are concentrically arranged and welded on At both ends of the cylindrical shell 1, each tube of the tube bundle 2 penetrates through the left tube plate 31, and then protrudes from the right tube plate 32, and the end of each tube is welded or expanded with the tube plate; The fluid inlet connecting pipe 5 and the fluid outlet connecting pipe 6 are respectively arranged on the sides of the two ends of the cylindrical housing 1 in order to facilitate the uniform distribution of the fluid after entering the housing and the convenience of collecting the fluid; it also includes several baffles 4, Each baffle 4 is obliquely arranged in the cylindrical shell 1, and each baffle 4 is composed of an elliptical curved side and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com