Depth detection apparatus

A depth detection and depth technology, applied in mechanical depth measurement and other directions, can solve the problems of inaccurate and reliable values, long operation time, and difficulty in finding the datum plane, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

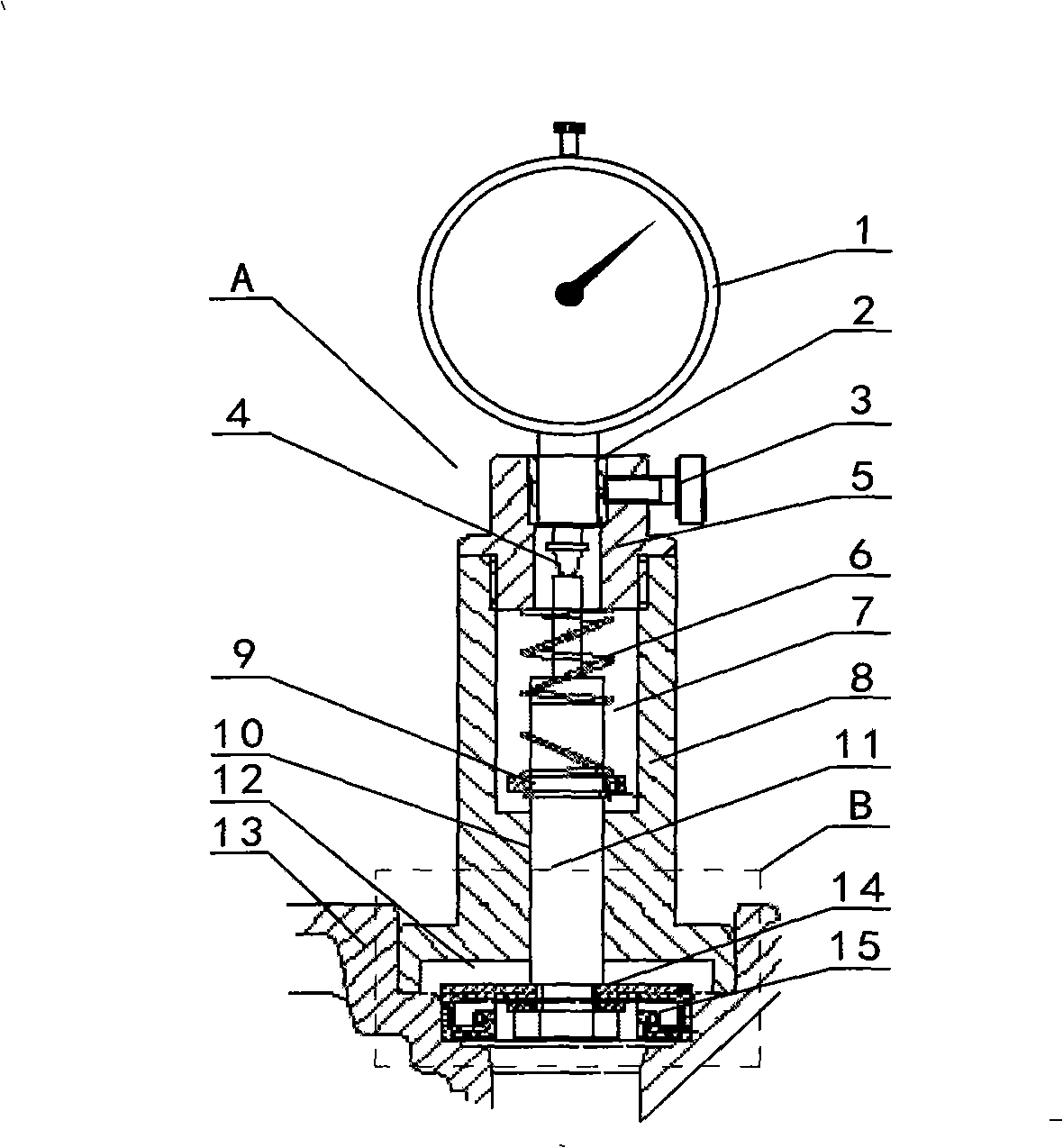

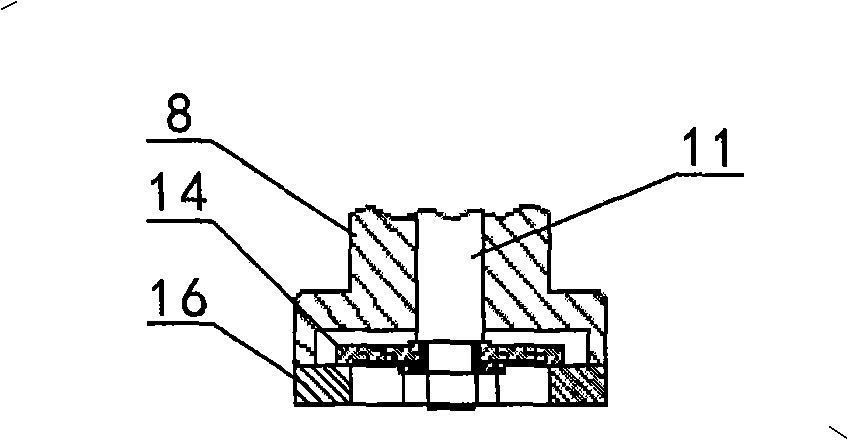

[0012] Such as figure 1 As shown, the structure of the depth detection device includes a dial gauge 1 and a sleeve 8; a central hole is provided in the sleeve 8, and its diameter is larger than the upper hole 7 and the lower hole 12 of the central hole; one end of the sleeve 8 is connected to the hollow Cover 5, the dial indicator 1 is fixed by the adjusting screw 3 inside the hollow upper cover 5, wherein, the outer surface of the dial indicator 1 inserted into the hollow upper cover 5 is covered with an elastic jacket 2, so that it can be fixed more firmly on the hollow Inside the cover 5; the probe 4 of the dial gauge 1 presses a measuring rod 11, and the measuring rod 11 slides freely in the center hole of the sleeve 8; the measuring rod 11 is covered with a spring 6, and one end of the spring 6 is connected with the hollow upper cover The bottom end is pressed against each other, and the other end is pressed against the stop block 9 fixed on the measuring rod 11; wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com