Thermostat apparatus

A thermostat and high-temperature cooling technology, which is applied to valve devices, instruments, valve operation/release devices, etc., can solve the problems of unstable temperature of coolant C and inability to control the opening of main valve 9, etc. Stabilize, increase temperature dominance, and suppress thermal expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

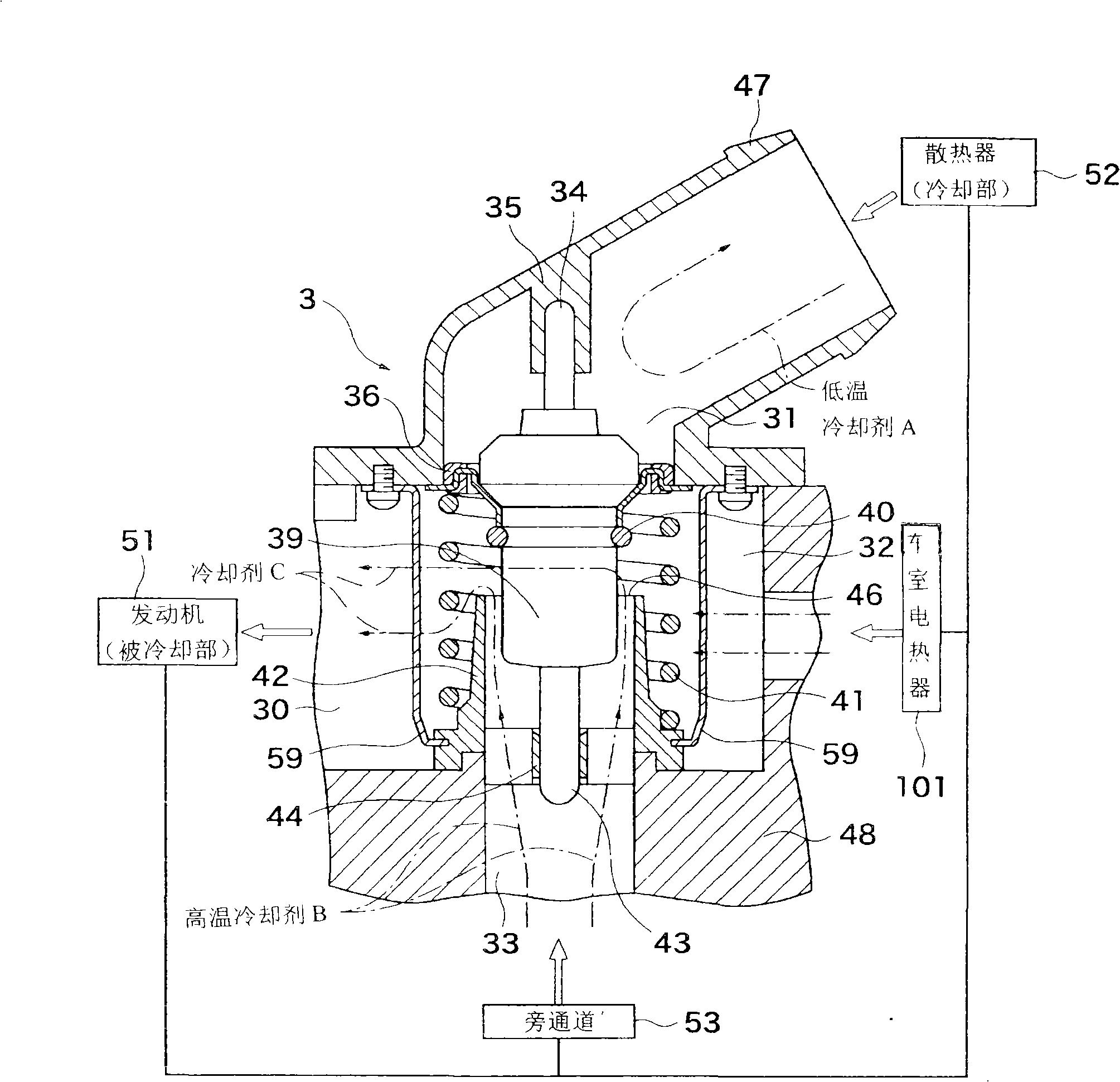

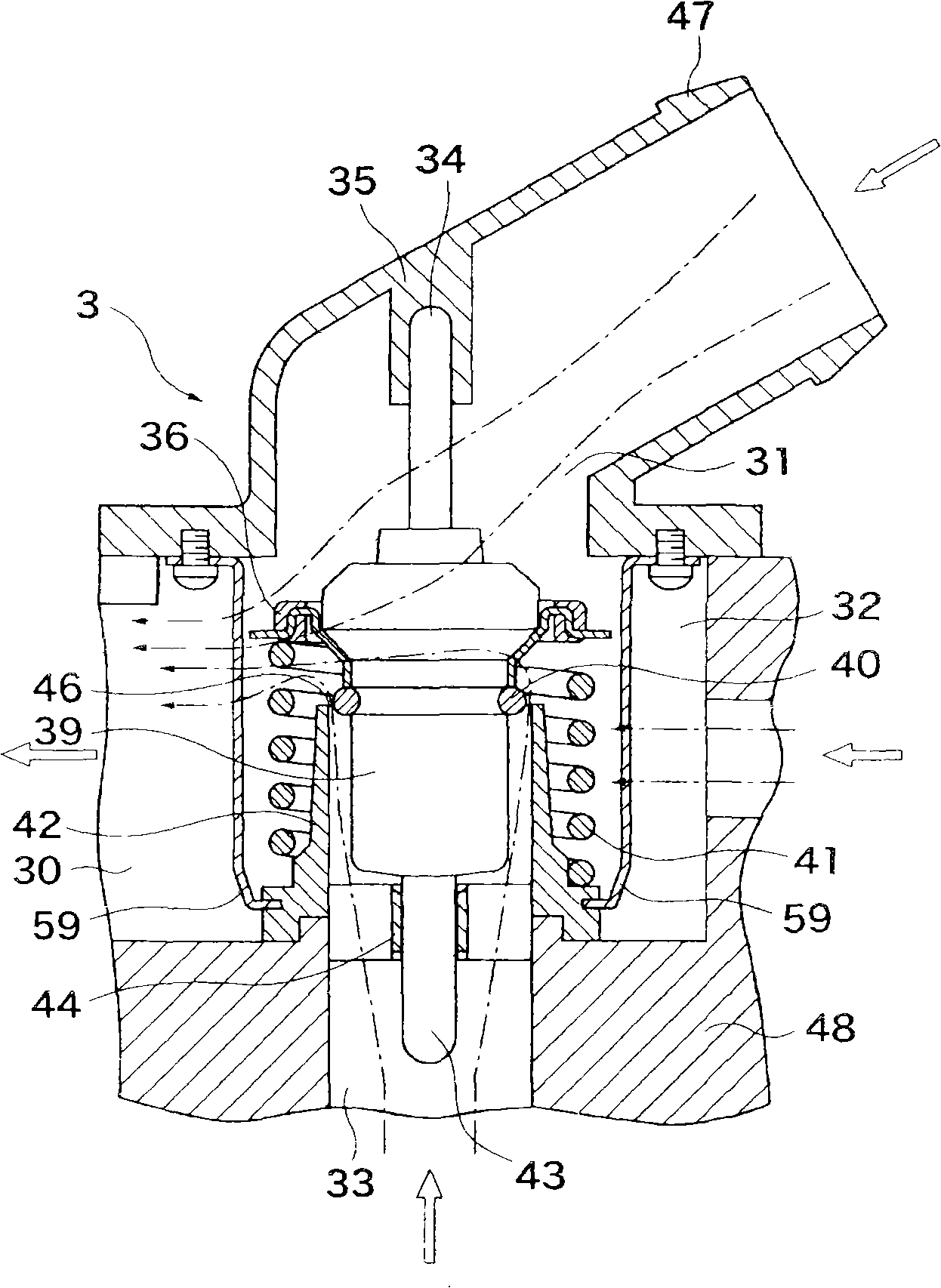

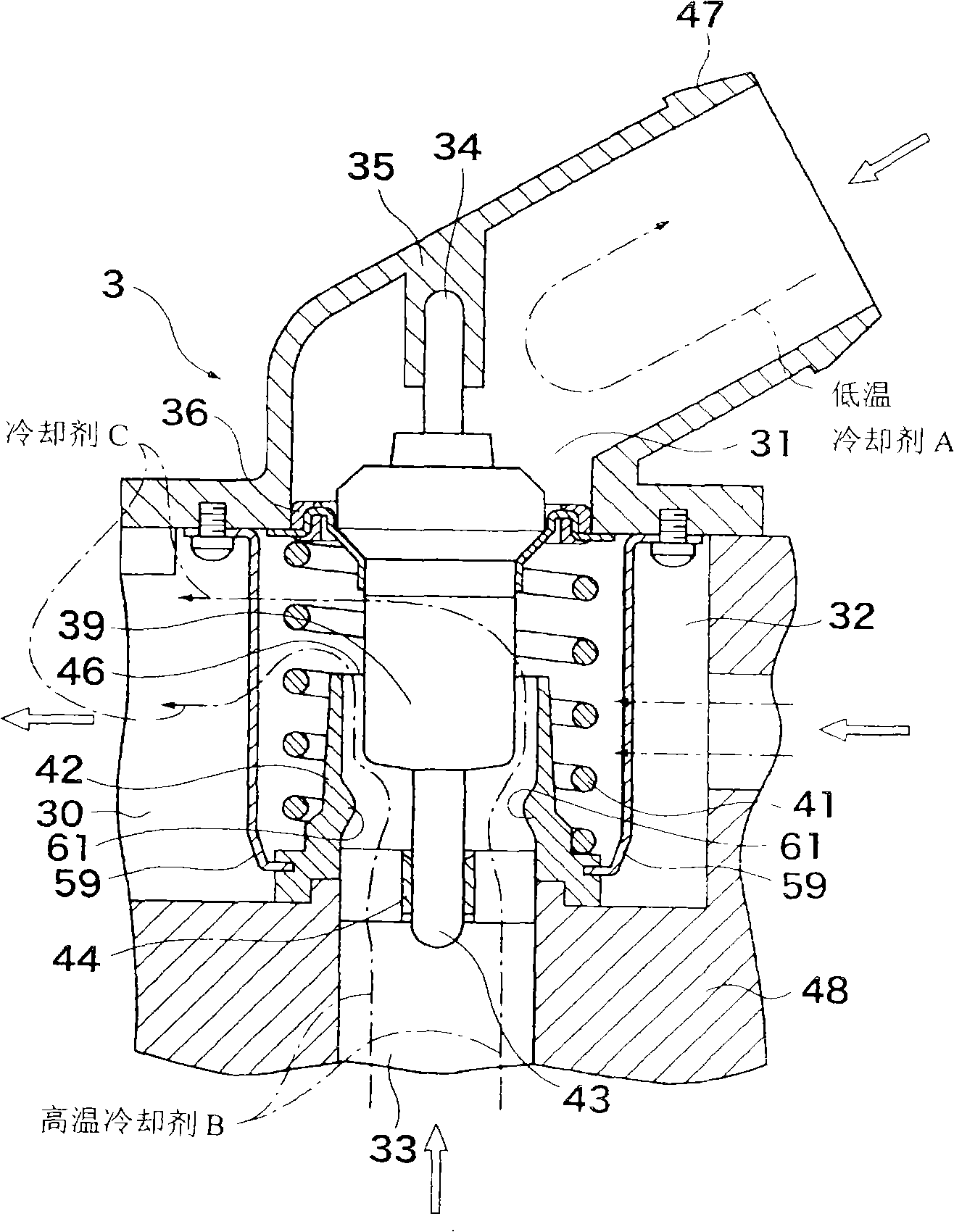

[0088] Hereinafter, as the best embodiment of the present invention, a thermostat device that can be used to control the cooling temperature of an automobile engine will be described in detail with reference to the accompanying drawings.

[0089] Figure 1a The overall structure of the thermostat device 3 of the present invention is shown. In this thermostat device 3, the low-temperature coolant A cooled by the radiator 52 and the high-temperature coolant B supplied from the engine (cooled part) 51 through the bypass passage 53 flow in, and by controlling these mixing ratios, the flow into the engine is controlled. 51 The temperature of the coolant C is within the range of the inlet control mode.

[0090] That is, in this control system, include: high-temperature coolant passage 33, the high-temperature coolant B that flows through engine 51 is directly sent to this high-temperature coolant passage 33 through bypass passage 53; Low-temperature coolant passage 31, flows through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com