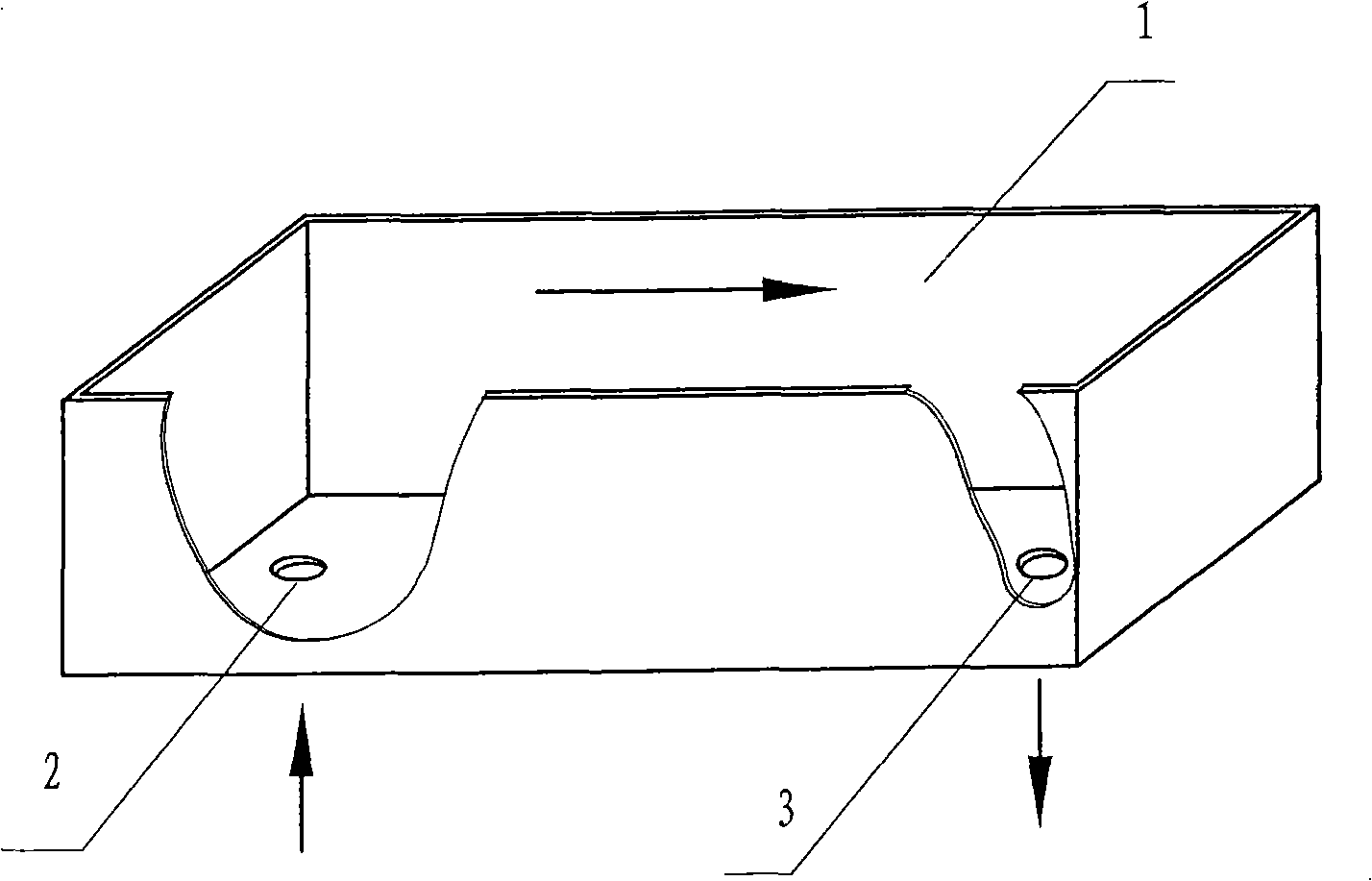

Water channel of plastic extrusion machine

A plastic extruder and water tank technology, applied in the field of water tank structure, can solve the problems of unfavorable cleaning, impurity dispersion, high water pressure, etc., and achieve the effects of convenient use and maintenance, easy to be scalded, and easy to clean impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

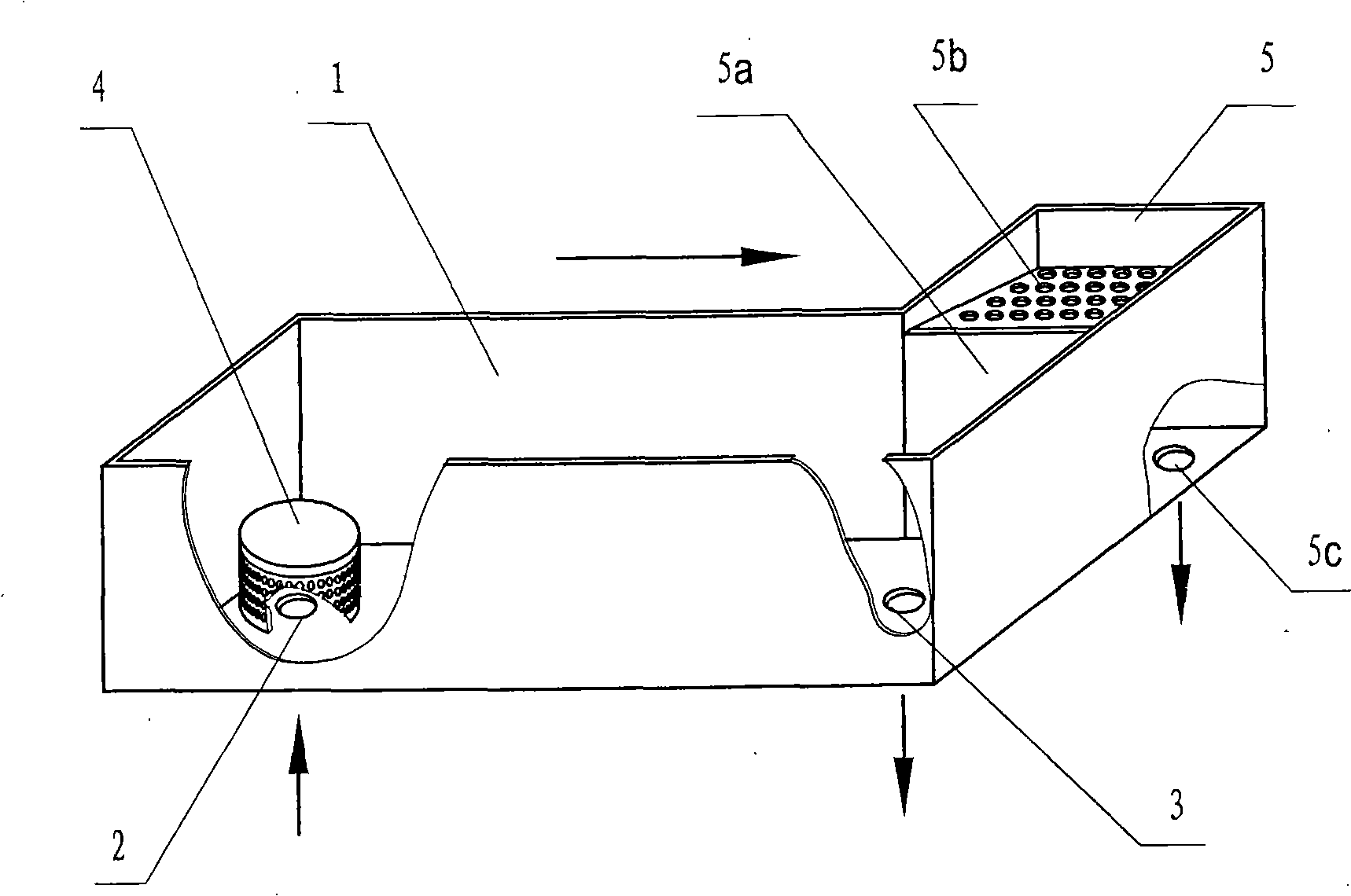

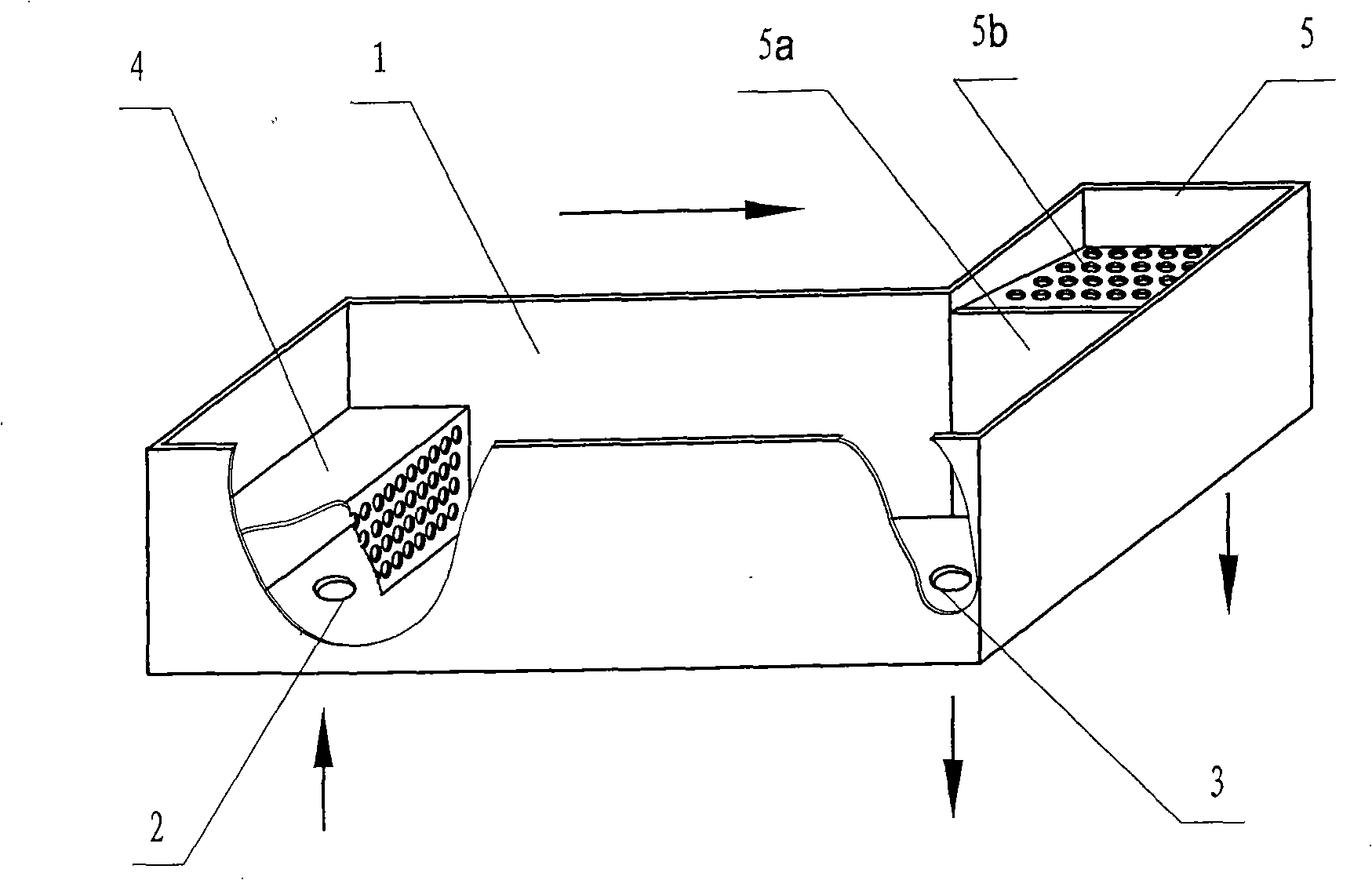

Embodiment 1

[0041] Such as figure 2 As shown, after the cooling water flows into the tank body 1 from the water inlet 2, the upward water flow will be blocked by the anti-scouring plate in the upper anti-scouring device 4, which effectively reduces the water pressure at the water inlet 2, and then the water flows through the mesh The leakage hole on the plate flows into the tank body 1 gently, and continuously flows towards the water outlet of the tank body. When the water level in the tank is higher than the height of the overflow plate 5a, it will overflow the overflow plate 5a, and pass through the upper inclined collector. The mesh on the miscellaneous plate 5b flows into the below, and flows out of the water tank from the water outlet 5c of the bottom, and the impurities floating with the water will stay on the mesh plate of the miscellaneous plate 5b, which is convenient for centralized removal.

[0042] Such as Figure 5 As shown, in order to prevent the operator from being scald...

Embodiment 2

[0045] Such as figure 2 The mesh plate on the periphery of the anti-scouring device 4 and such as Figure 4 The mesh plate with the filter screen cover above the water outlet 3 shown is a wire mesh woven by stainless steel wires, and the rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com