Mechanical seal gear pump

A mechanical seal, gear pump technology, applied in mechanical equipment, rotary piston machinery, pumps, etc., can solve the problem that the pulse damper cannot completely eliminate the pulse, and achieve the effect of light weight, good self-priming performance, and avoidance of pulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

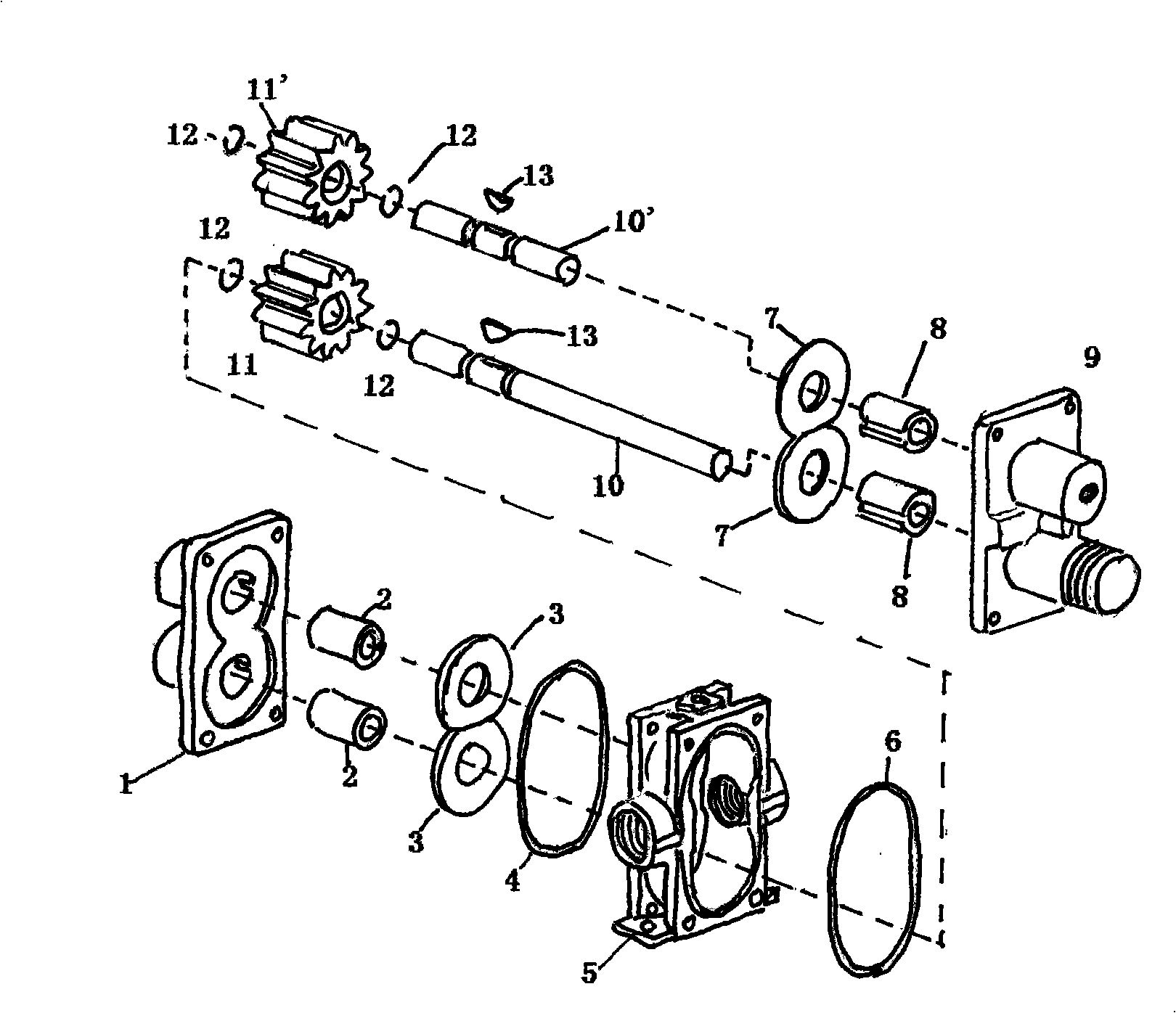

[0009] The present invention will be further described below in conjunction with accompanying drawing.

[0010] On the driving shaft 10 and the driven shaft 10' in the middle shell 5, respectively install the driving gear 11 and the driven gear 11' with precise machining and complete meshing degree, and the driving gears are equipped with two snap rings and a key. The shaft 10 and the driven shaft 10' are used to fix the driving gear 11 and the driven gear 11', and the housing O-rings 4, 6 and wear-resistant plates 3, 7 at the front and rear ends of the middle shell 5 are used to ensure sealing and prevent wear. Both the driving shaft 10 and the driven shaft 10' in the cavity of the shell 5 are provided with two annular ring grooves, and a radial key groove is arranged between the two ring grooves, and the ring ring 12 is set in the ring groove. The key 13 is embedded in the keyway to serve the purpose of fixing the gear. When the driving shaft 10 rotates, it drives the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com