Super-fine super-anti-bending super-high intensity guiding optical cable

An ultra-high-strength, anti-bending technology, applied in the fiber mechanical structure and other directions, to achieve ultra-high tensile strength, reduce limitations, and reduce the proportion of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] To manufacture the optical cable of the present invention, two schemes can be adopted: 1. Refit the existing tight-sleeve optical fiber extrusion production line to precisely control the relative position of the reinforcing yarn and the optical fiber; 2. Refit the optical fiber doubling machine or coloring machine to precisely control The location of the optical fibers and reinforcing yarns.

[0018] The optical cable structure of the present invention will be specifically described below in conjunction with the accompanying drawings.

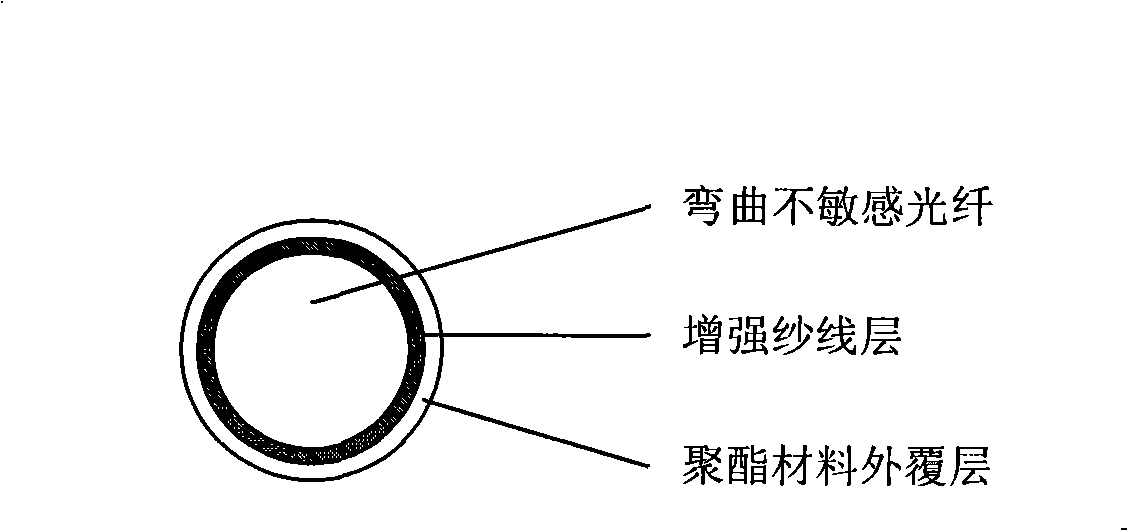

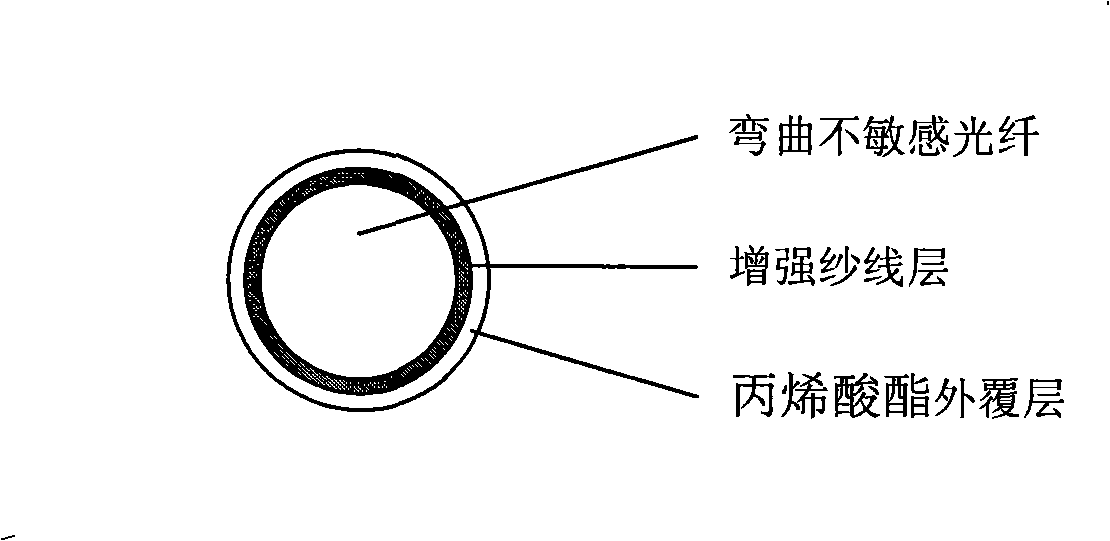

[0019] figure 1 Shown is a specific embodiment of the invention.

[0020] see figure 1 , figure 1 The inner core of the optical cable shown is a bend-insensitive optical fiber, and the optical fiber is covered with 2-12 strands of reinforcing yarn (depending on the linear density of the reinforcing yarn). The reinforcing yarn needs to be soaked with polyester material, and then coated with polyester Ester material (cured by water coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com