Touch control display panel

A touch display panel and substrate technology, applied in static indicators, instruments, electrical digital data processing, etc., can solve problems affecting the uniformity of touch sensing, poor touch function, affecting the minimum external force of sensing touch, etc. , to achieve the effects of increasing the sensing sensitivity and overall uniformity, reducing poor touch function or short circuit, and making the design more flexible and diverse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

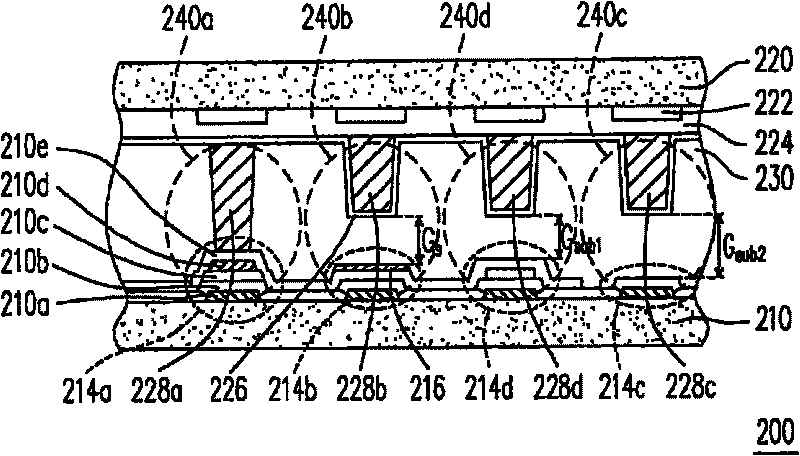

[0083] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments will be described in detail below together with the accompanying drawings.

[0084] It should be noted that the detailed structures presented as examples in the following different embodiments can be combined, replaced or omitted under reasonable circumstances, so as to meet different actual needs. Those skilled in the art should be able to understand the spirit and technical characteristics of the present invention after referring to the description of the following embodiments, and make reasonable changes and applications without departing from the scope of the spirit of the present invention. In addition, in order to facilitate the description and make the description easier to understand, the same reference numerals are used below to denote similar elements, and repeated text descriptions may be omitted.

[0085] Figure 2A and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com