Capacitance touching control panel and detection method thereof

A technology of a capacitive touch panel and a detection method, which is applied to the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problems of wasting manufacturing costs, reducing production capacity utilization, occupation, etc., and reducing manufacturing costs. , the effect of increasing capacity utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The advantages and spirit of the present invention can be further understood through the following detailed description of the invention and the accompanying drawings.

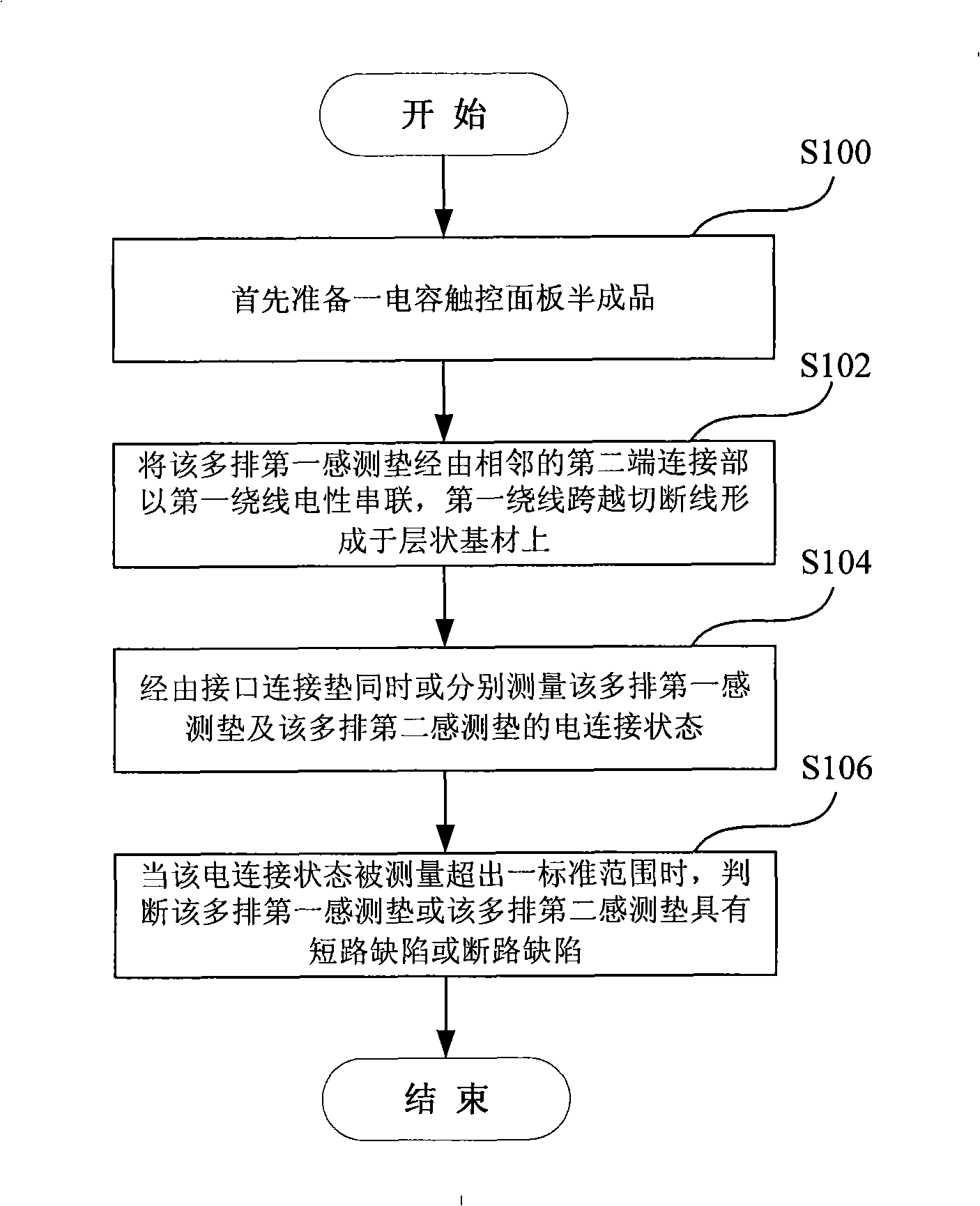

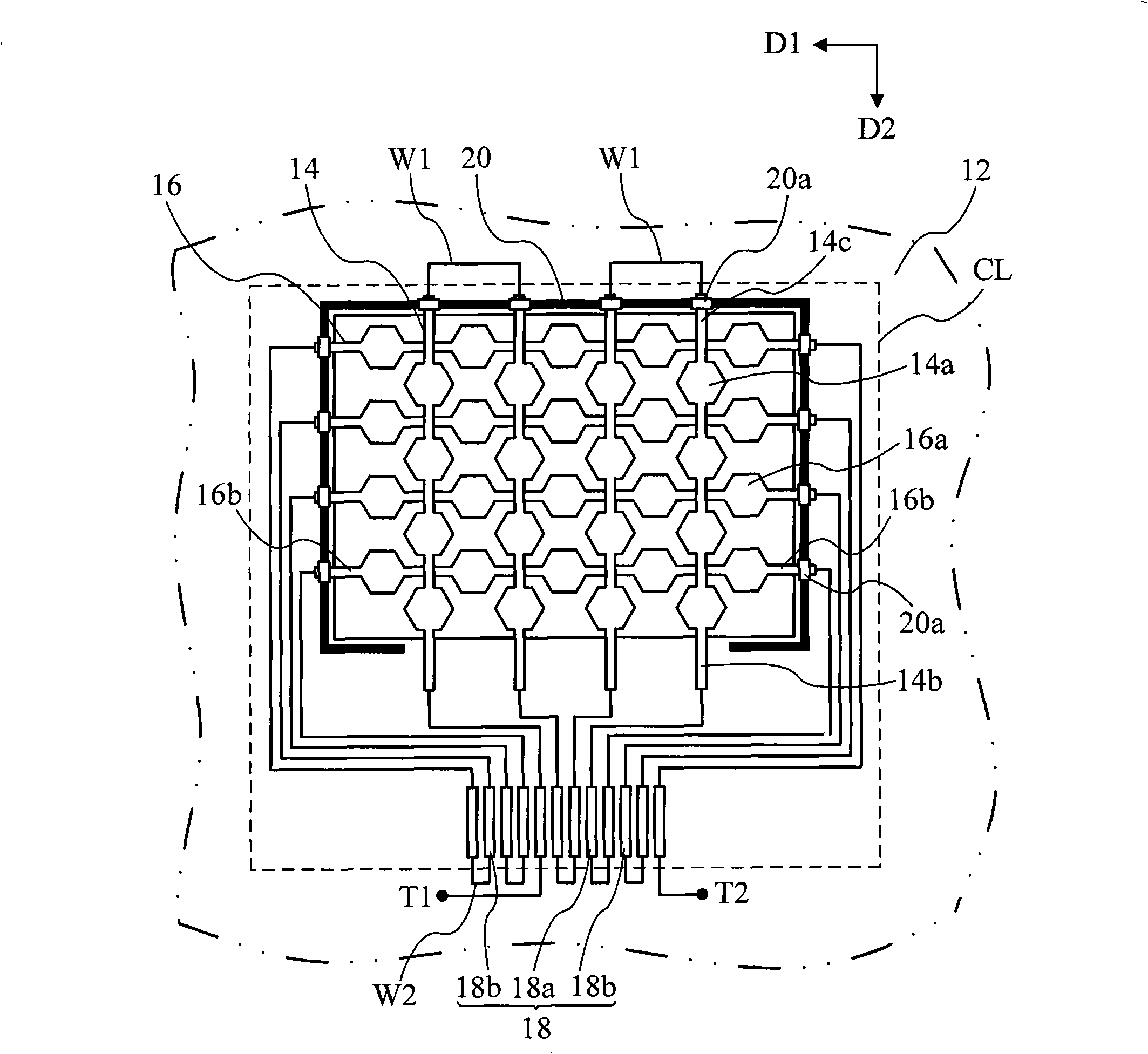

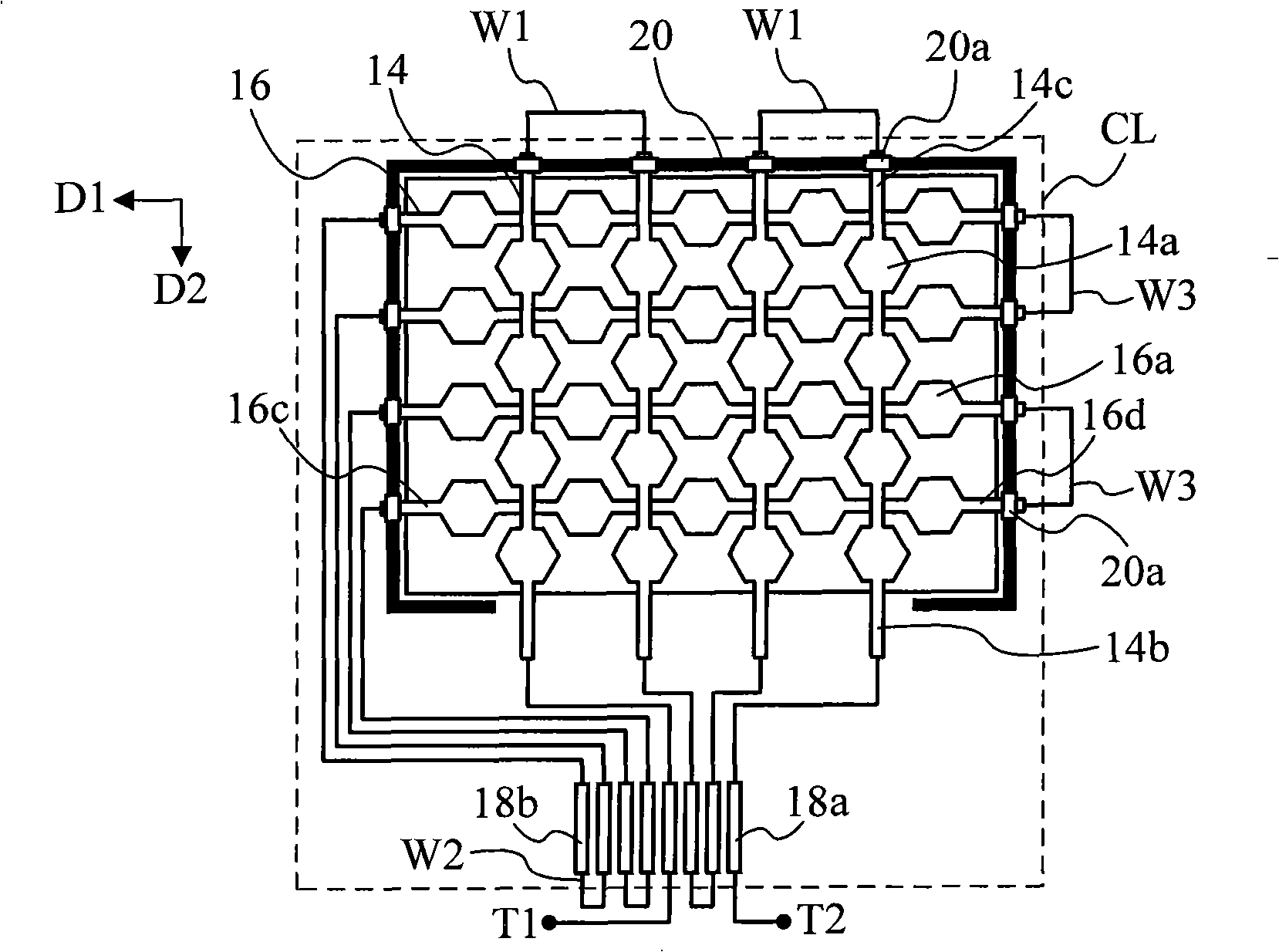

[0040] see figure 1 and figure 2 . figure 1 It is a flow chart illustrating the detection method of the capacitive touch panel according to the first embodiment of the present invention. figure 2 is a partial schematic diagram illustrating a semi-finished product of a capacitive touch panel according to the first embodiment, that is, the semi-finished product of a capacitive touch panel may include a plurality of capacitive touch panels, and figure 2 Only the area containing a capacitive touch panel is shown, whose boundaries are indicated by chain lines. According to the first specific embodiment, as shown in step S100, the detection method of the capacitive touch panel of the present invention includes first preparing a semi-finished capacitive touch panel, such as figure 2 shown. The capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com