Linear-motion actuator

A linear actuator, axis direction technology, applied in the direction of electric components, casing/cover/support, control mechanical energy, etc., can solve the problem of size increase, and achieve the effect of reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

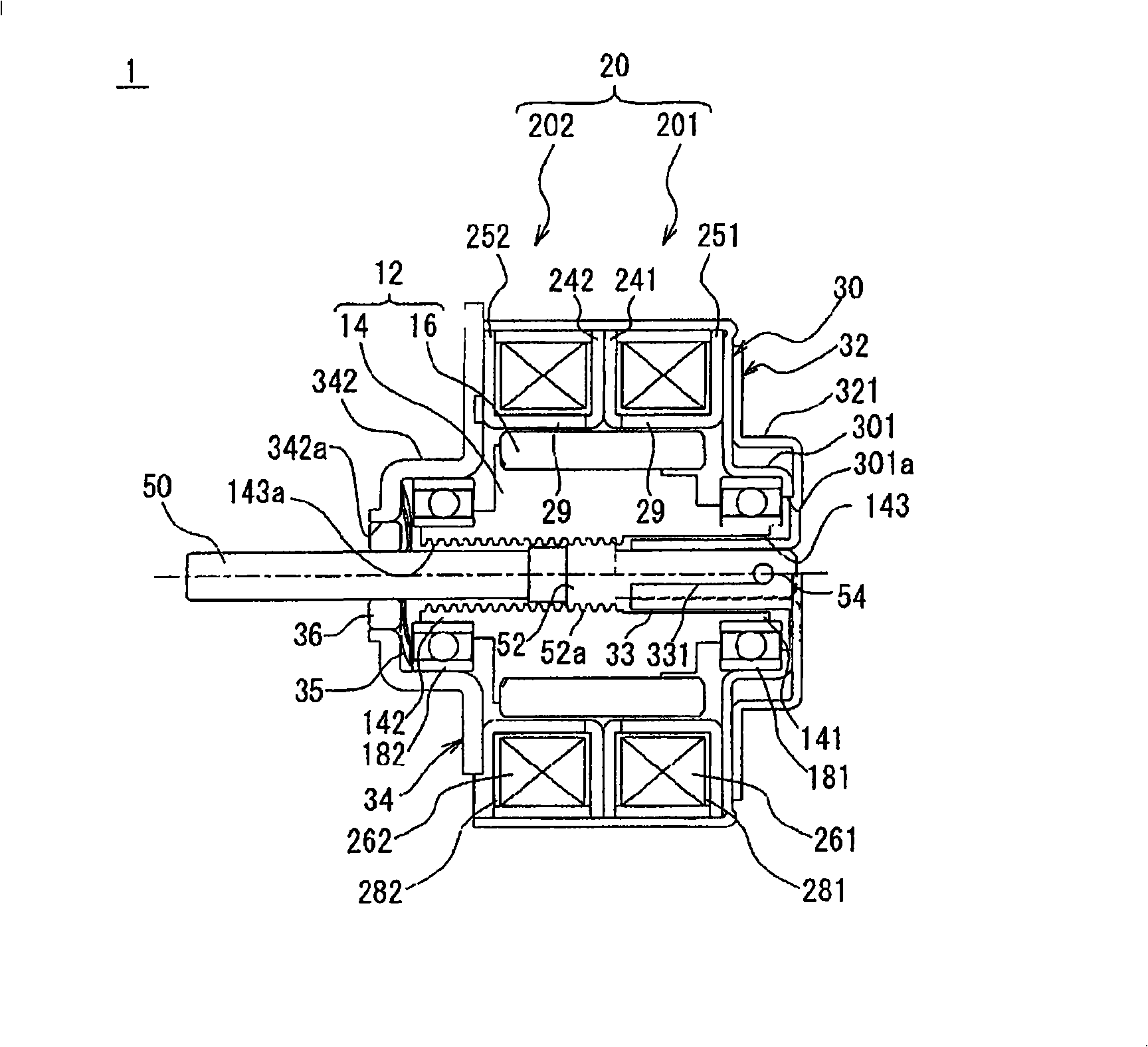

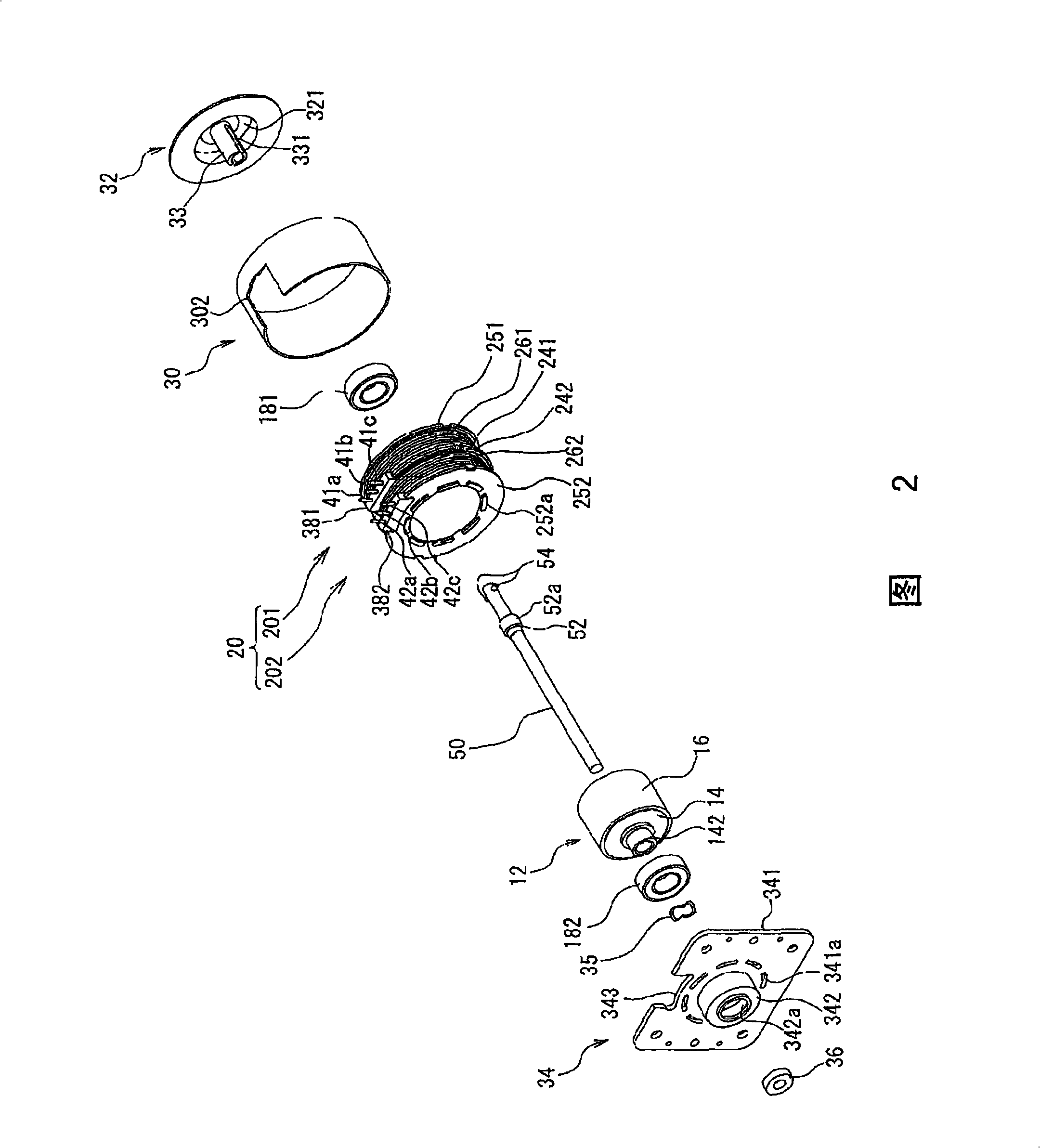

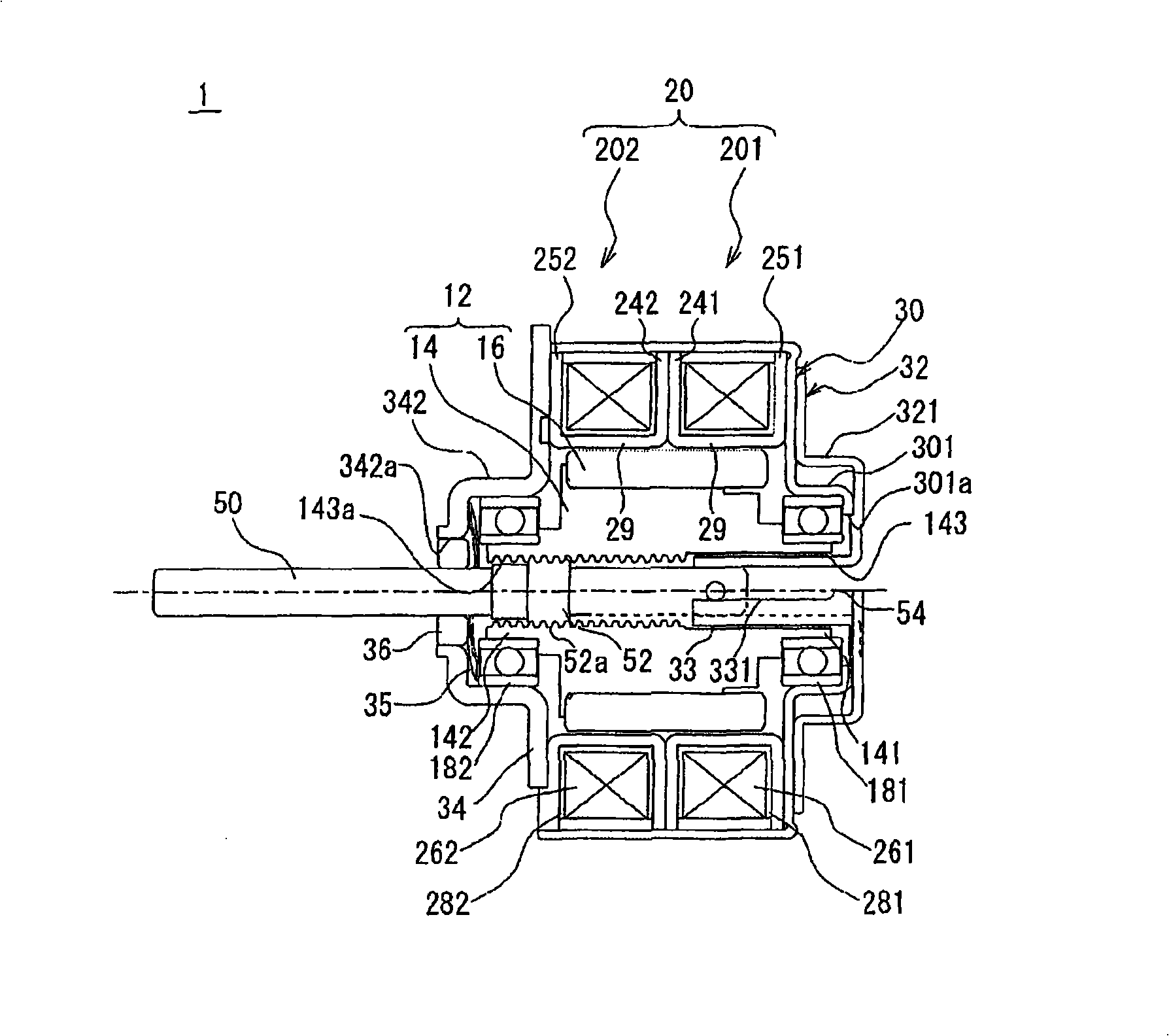

[0042] Embodiments of the linear actuator of the present invention will be described in detail below with reference to the drawings.

[0043] figure 1 is a sectional view of the linear actuator 1 according to the first embodiment of the present invention, and FIG. 2 is an exploded perspective view of the linear actuator 1 . In this linear actuator 1, the output shaft 50 moves forward and backward along the axial direction with a predetermined stroke amount ( figure 1 Actuator that advances to the left and backs to the right). In the following description, the axial direction in which the output shaft 50 protrudes ( figure 1 The left side of the middle) is called the output side, and the opposite axis direction ( figure 1 The right side in the center) is called the anti-output side.

[0044] The linear actuator 1 of this embodiment includes: a fixed-side member 30 having a stator 20 , a rotor 12 supported so as to be rotatable about an axis relative to the fixed-side member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com