Pprocess for producing a stampable reinforced composite semi-finished product

A technology of composite materials and semi-finished products, applied in the direction of coating, etc., can solve the problems affecting the cost and price of composite semi-finished products, excessive non-uniformity, defective mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

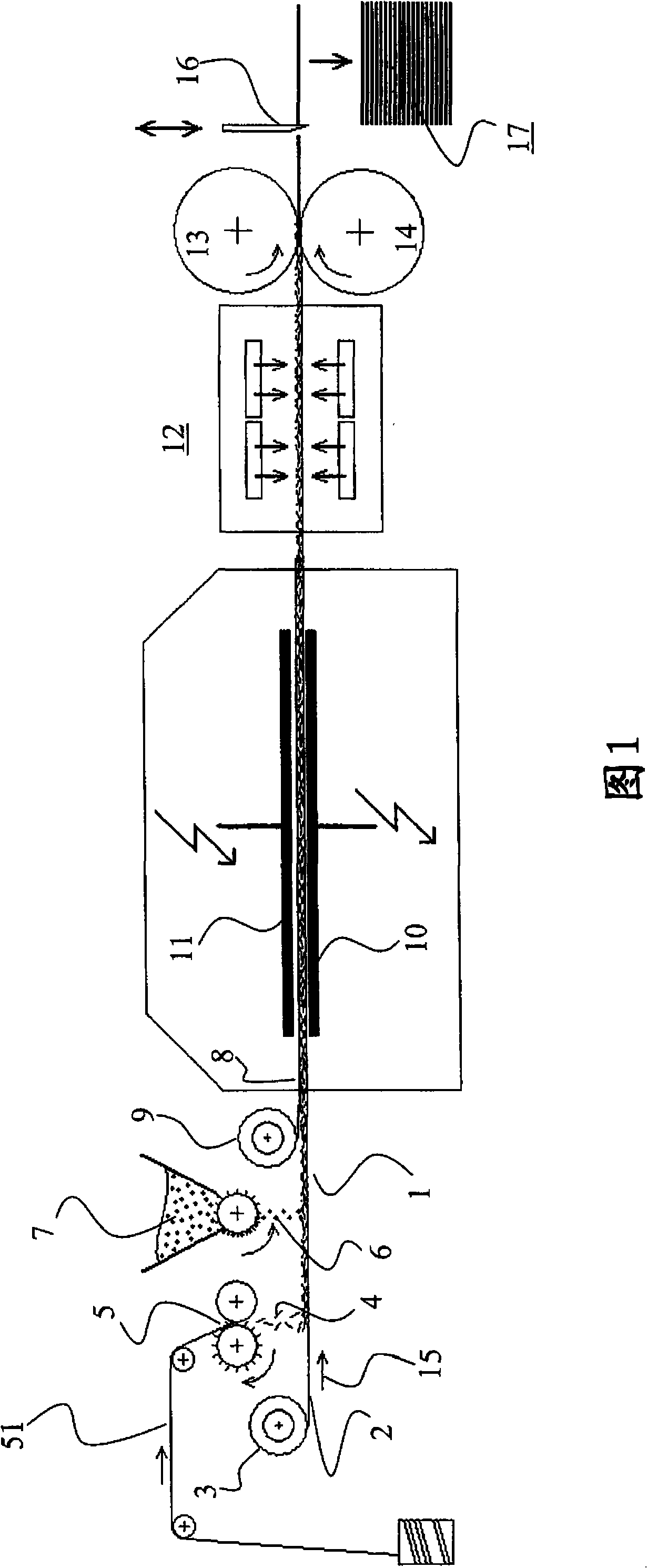

[0047] The accompanying drawing thus illustrates a production line for semi-finished products made of composite material according to one embodiment of the method which is the subject of the invention. In this production line, the conveyor device 1 comprises a conventional conveyor whose belt advances in the direction indicated by the arrow 15 .

[0048] During a first step illustrated by the figures, the lower layer 2 is deposited on the belt of the conveyor 1 . The lower layer 2 is in this case in the form of a film wound on a roll 3 and unrolled synchronously with the advancement of the conveyor 1 .

[0049] According to the invention, the lower layer 2 comprises a plastic whose softening point is lower than that of the reinforcing fibers constituting the semifinished product obtained according to the method that is the subject of the invention. This lower layer 2 is made to bond with the rest of the composite semi-finished product during a heat treatment step as described...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com