Oil atomizing sprayer of lubricant oil for transposition head

An atomizing spray and lubricating oil technology, which is applied to the device, coil manufacturing, electrical components and other directions of coating liquid on the surface, which can solve the problem of uneven oil coating on the surface of the transposed wire, uncontrollable amount of lubricating oil, and pollution of the working environment. and other problems to achieve the effect of preventing pollution, reducing waste and uniform oil volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

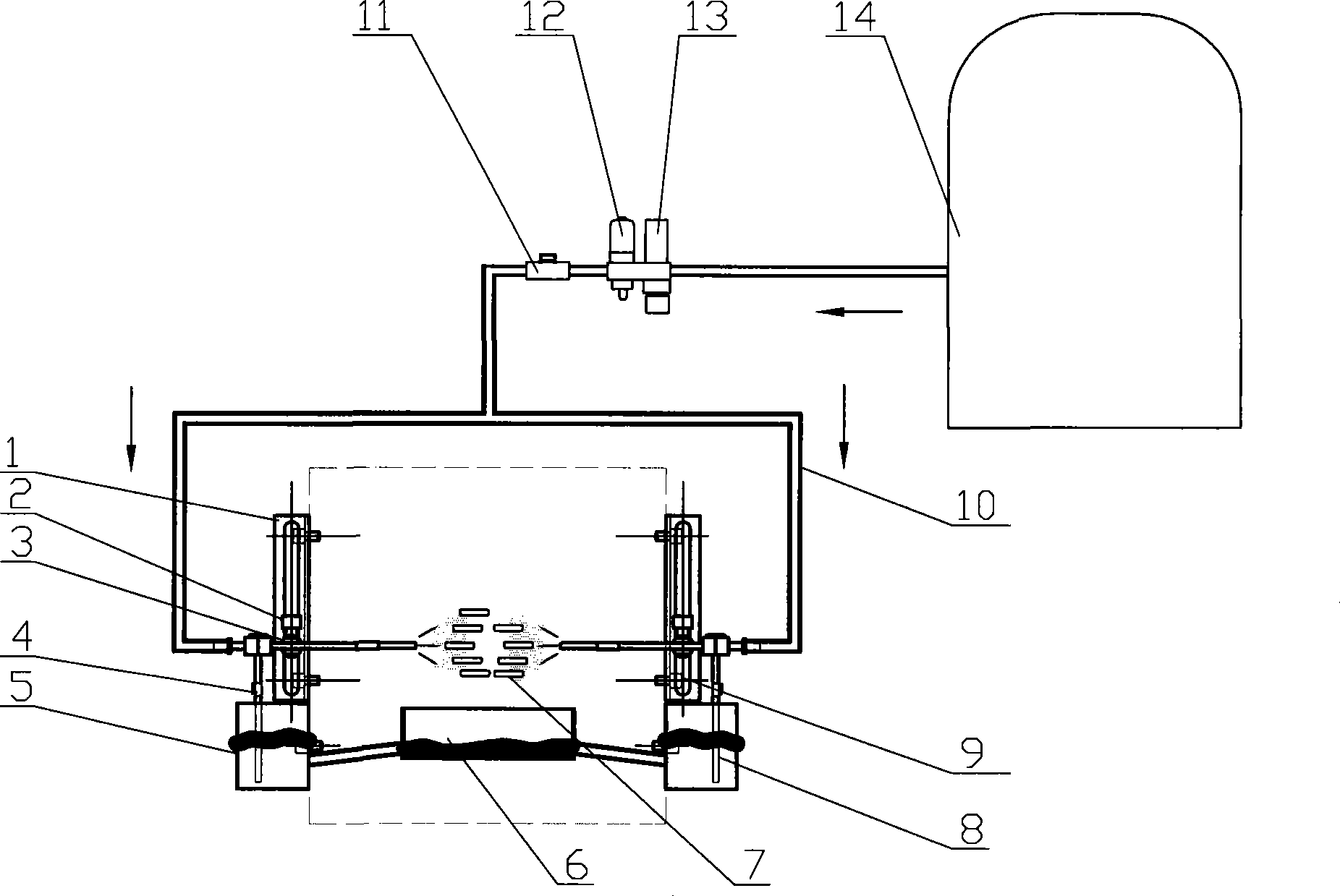

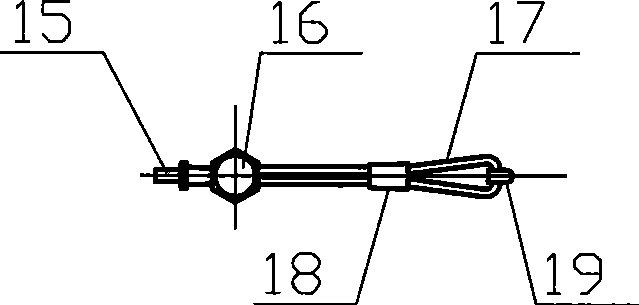

[0011] like Figure 1 ~ Figure 2 As shown, it includes bracket 1, nozzle fixing fixture 2, base regulator 3, hydraulic throttle valve 4, oil storage tank 5, oil guide tank 6, transposition wire 7, oil suction pipe 8, fastening nut 9, high-pressure air pipe 10, pneumatic Throttle valve 11, pressure regulating valve 12, filter valve 13, air compressor 14, high-pressure air inlet 15, oil suction chamber 16, fuel injection pipe 17, fixing clip 18 and spray head 19, etc.

[0012] In the present invention, the air compressor 14 is sequentially connected to the filter valve 13, the pressure regulating valve 12, and the pneumatic throttle valve 11 through pipelines. The pneumatic throttle valve 11 is connected to the high-pressure air pipe 10 through the pipeline connector, and the high-pressure air pipe 10 is connected to the spraying parts. , the spray part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com