Laser processing device and laser processing method

A technology for laser processing and processed objects, which is applied in laser welding equipment, metal processing equipment, installation, etc., and can solve problems such as the inability to use laser processing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

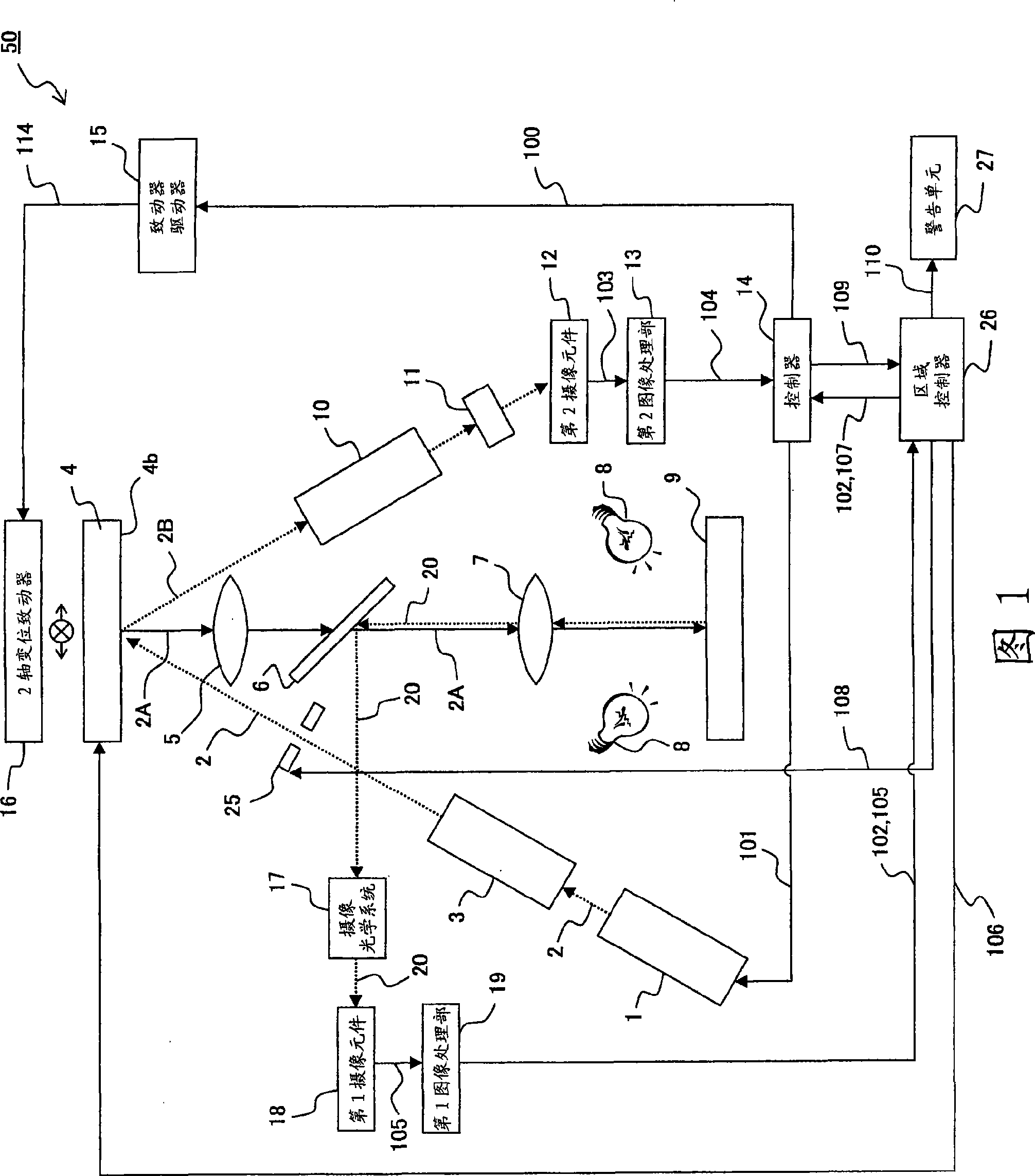

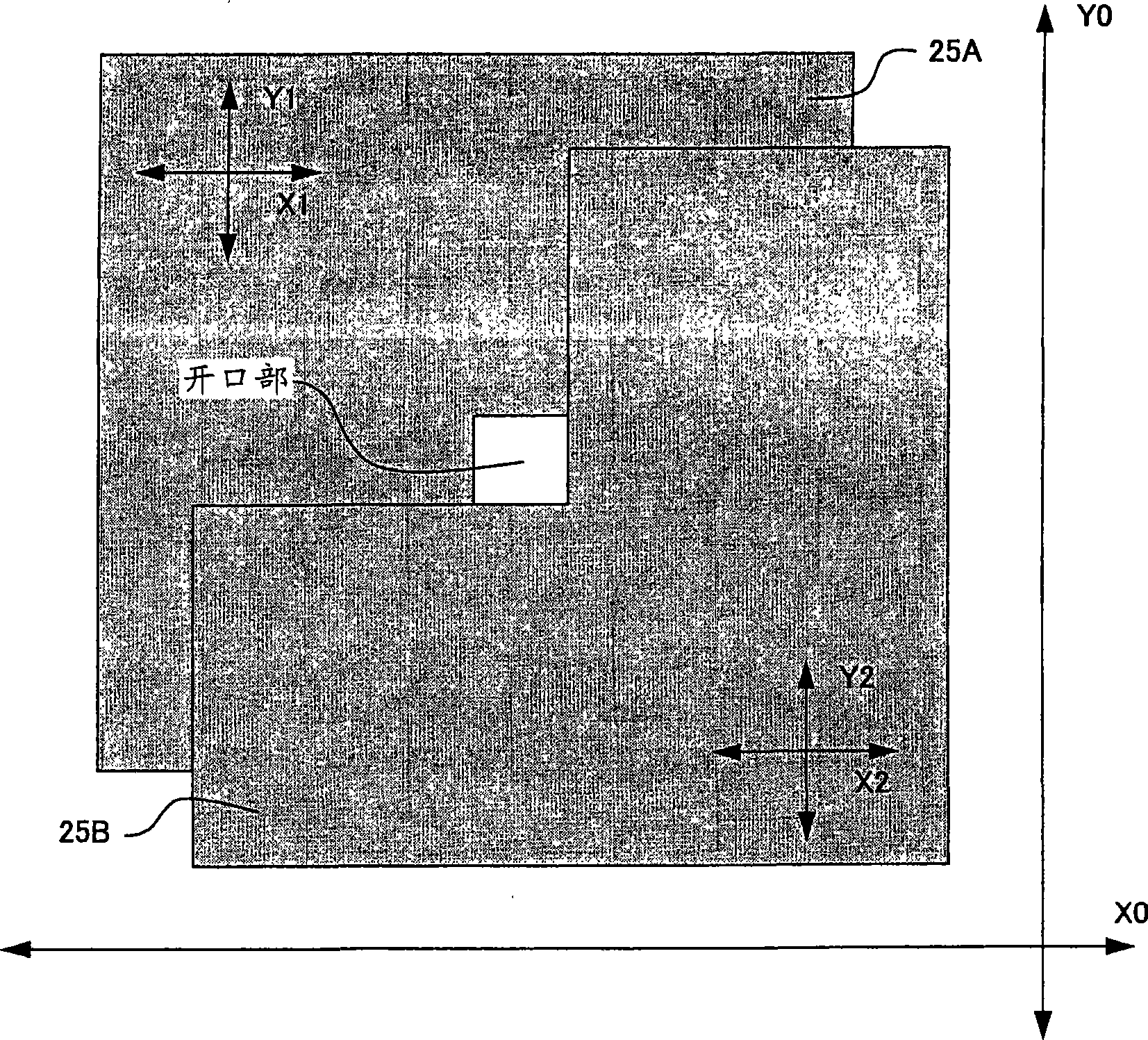

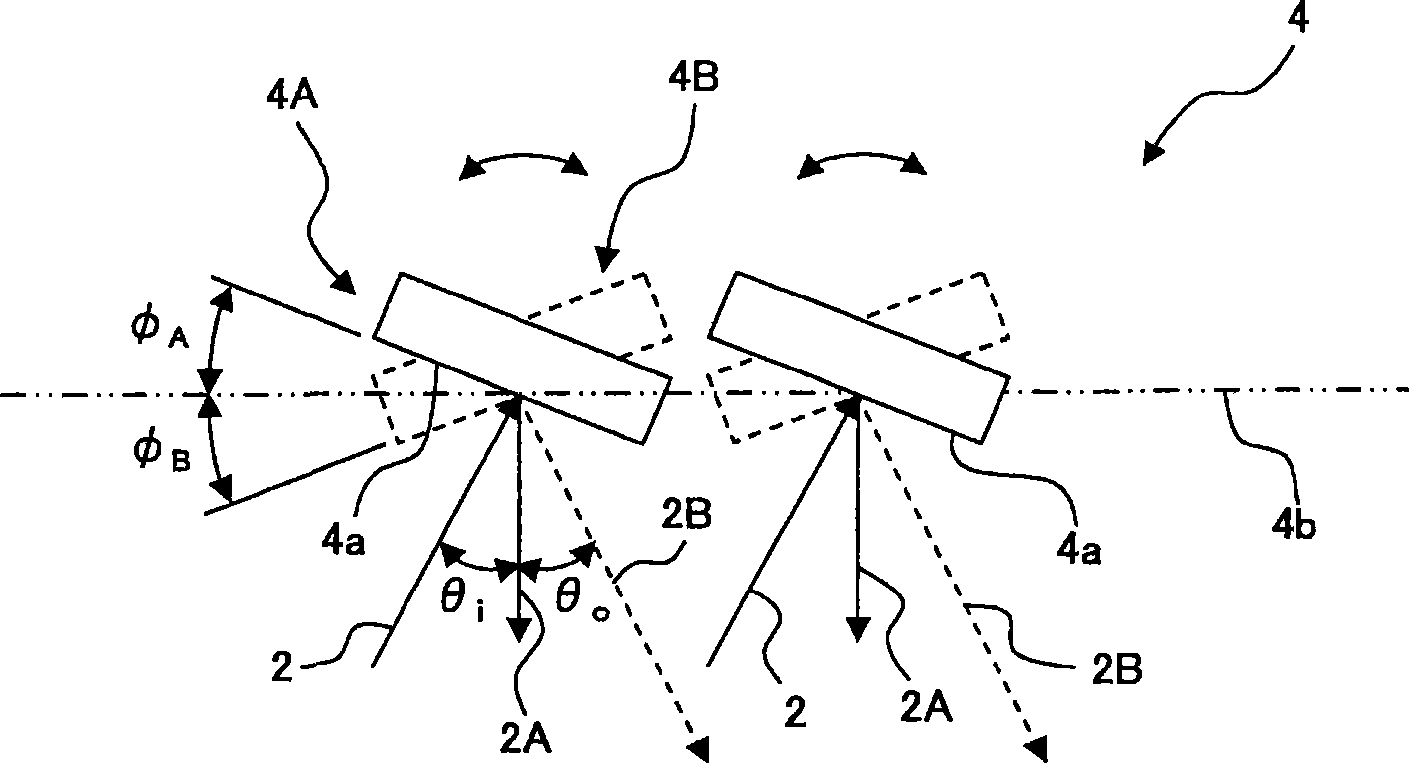

[0048] The laser processing apparatus according to the first embodiment of the present invention will be described.

[0049] FIG. 1 is a schematic configuration explanatory diagram for explaining a schematic configuration of a laser processing apparatus according to a first embodiment of the present invention. figure 2 It is an explanatory drawing for demonstrating the structure of the slit of the laser processing apparatus concerning 1st Embodiment of this invention. image 3 It is a cross-sectional explanatory view for explaining the configuration and operation in the cross-sectional direction of the microlens array of the laser processing apparatus according to the first embodiment of the present invention. Figure 4It is a schematic plan explanatory view showing the microlens array of the laser processing apparatus according to the first embodiment of the present invention viewed from the reflective surface side, and a plan view showing an example of an image on a workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com