Bead feed mechanism of full-automatic charging and blanking switcher and bead feed method thereof

A fully automatic and transfer technology, which is applied in the direction of machine tools, grinding machines, metal processing equipment, etc., which are suitable for grinding the edge of workpieces, and can solve the problems of labor consumption, high replacement cost, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

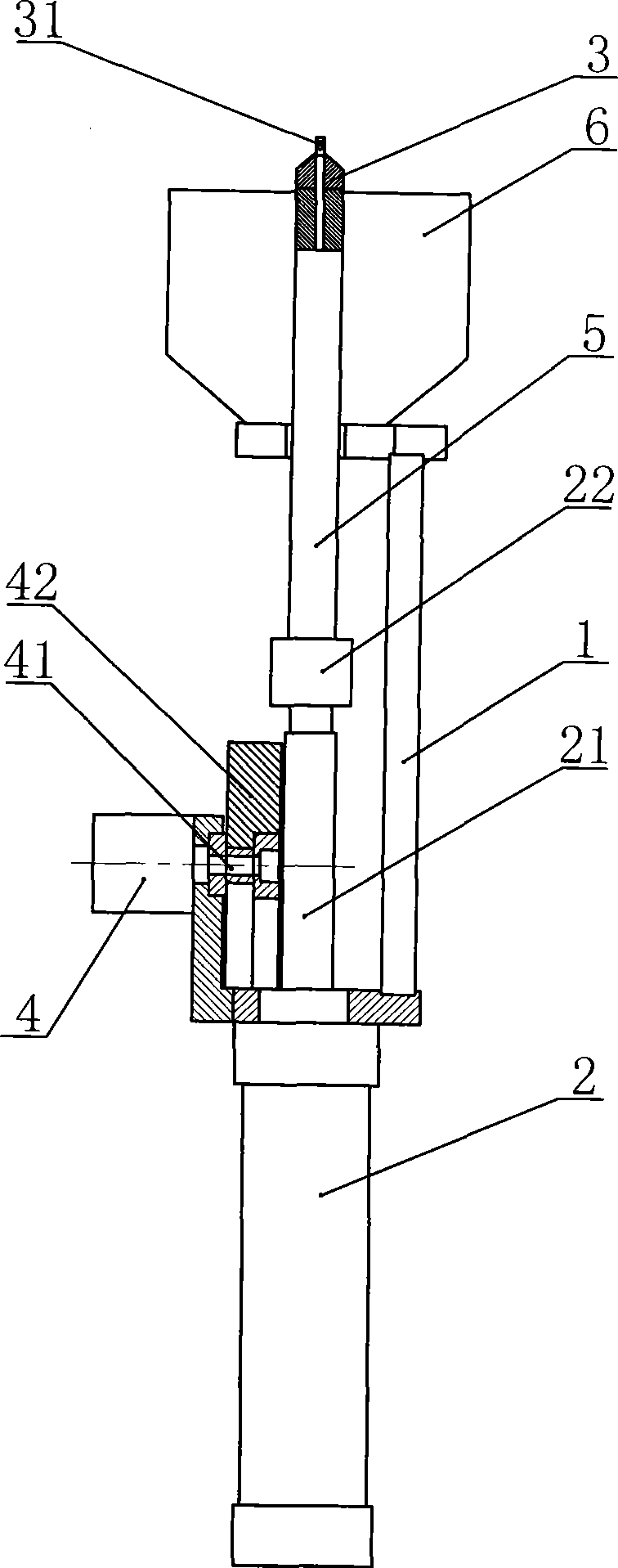

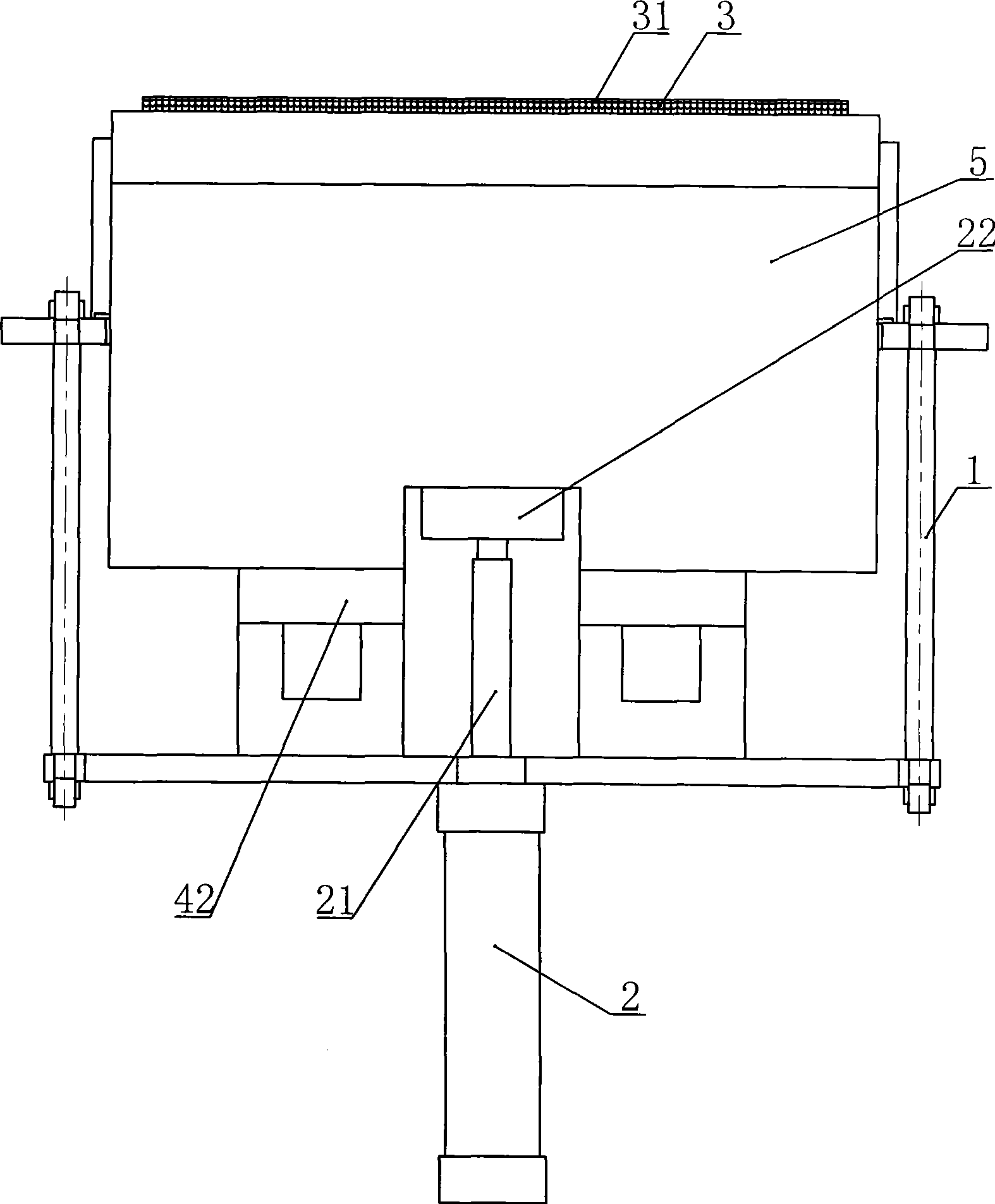

[0016] Such as Figure 1-2 The specific embodiment of the present invention shown comprises support 1, and the bottom of described support 1 is equipped with bead-feeding cylinder 2, and the upper end of described support is fixedly provided with holding box 6, and the piston rod of this bead-feeding cylinder 2 21 can move through the bottom of the bracket 1, and the piston rod 21 is provided with an upper bead plate 3 linked with it, the upper bead plate 3 can move through the bottom of the material box 6, the upper bead plate 3 Die pins 31 are fixed side by side on the upper side. In addition, the bracket 1 described in this embodiment is provided with a vibration bead cylinder 4 facing the side wall of the piston rod 21 of the bead delivery cylinder 2. The piston rod 41 of the vibration bead cylinder 4 The head end is fixedly provided with a vibration plate 42, and the upper end of the described bead delivery cylinder piston rod 21 is fixedly provided with a vibration block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com