Pearl calcium ion particle and preparation thereof

A calcium ion and pearl technology, applied in the field of pearl calcium ion particles and their manufacture, can solve the problems of water containing impurities and bacteria, and having no effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

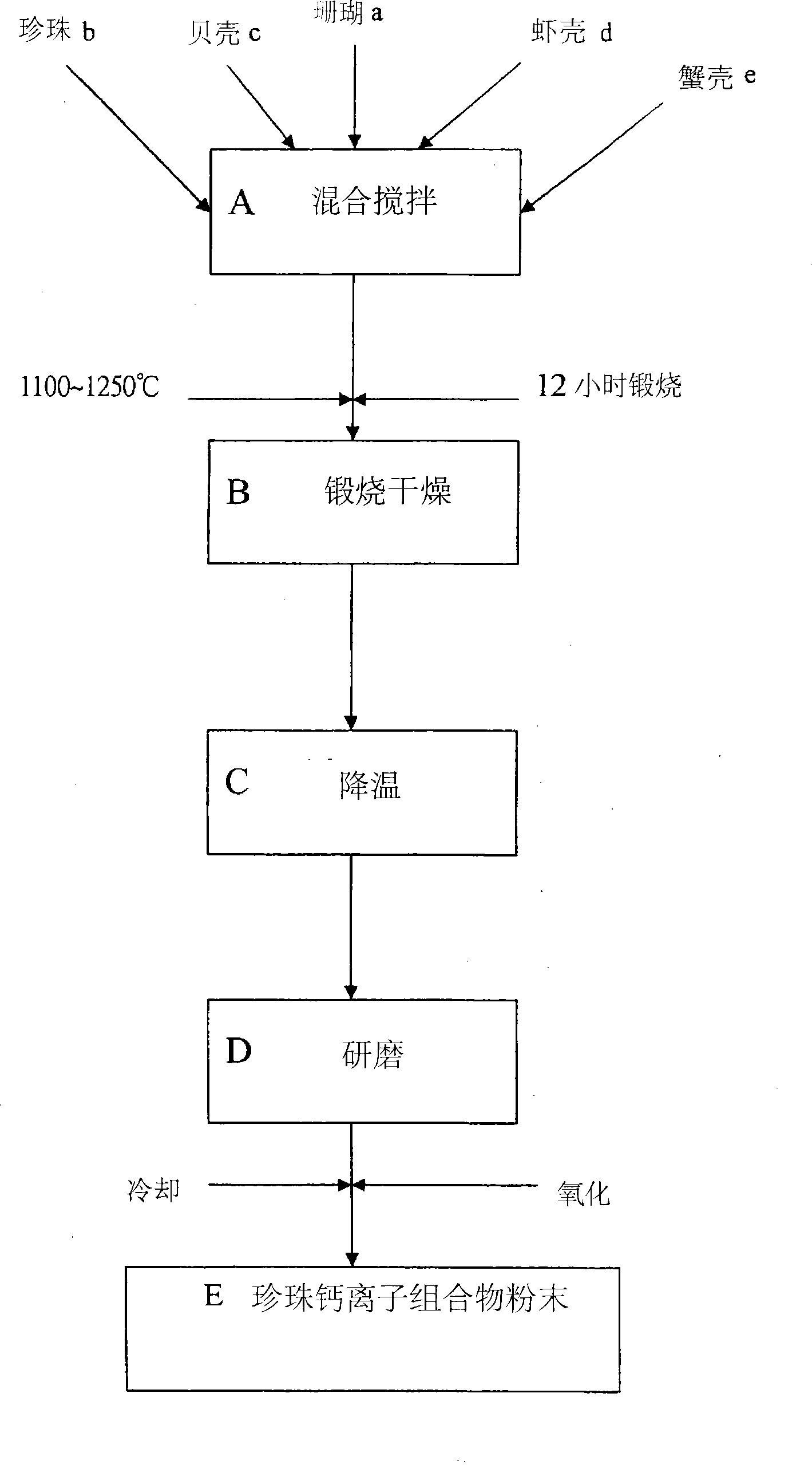

[0012] see figure 1 Shown, the present invention is a kind of manufacture method of pearl calcium ion particle, and its manufacture step is:

[0013] (1) First, pearl b (8-12wt%), coral a (58-62wt%), pearl shell c (8-12wt%), shrimp shell d (8-12wt%) and crab shell e (8-12wt%) %) and other ingredients are mixed and stirred A to make each ingredient evenly mixed with each other:

[0014] (2) Then calcine and dry B at a temperature of 1100°C-1250°C for 12 hours to remove unnecessary impurities:

[0015] (3) carry out cooling C again;

[0016] (4) Carry out grinding D step;

[0017] (5) Then put into the container and pour into the oxygen with higher purity to carry out oxidation, after cooling, the pearl calcium ion composition powder E can be obtained, and the pearl calcium ion composition powder E contains at least more than 90% of calcium content.

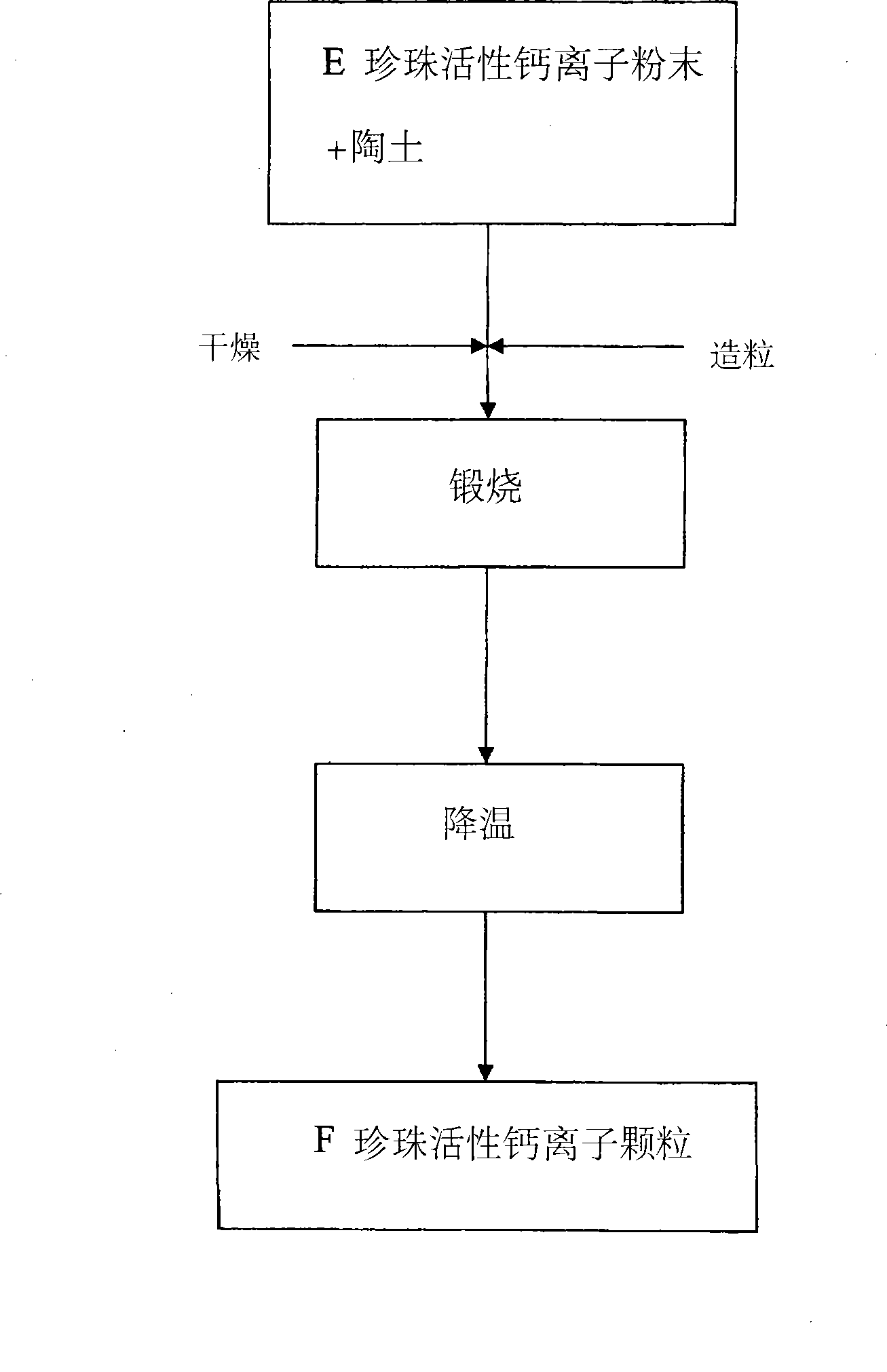

[0018] (6) See figure 2 As shown, the manufacturing process figure 1 The prepared pearl calcium ion composition powder E ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com