Metal gallium longitudinal temperature gradient solidification purification apparatus and method

A temperature gradient and purification method technology, applied in the field of metal gallium longitudinal temperature gradient solidification and purification equipment, can solve the problems of high production cost, restrictions on the application of high-purity metal gallium materials, production difficulties, etc., and achieve convenient purification and quantitative control, reduce Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

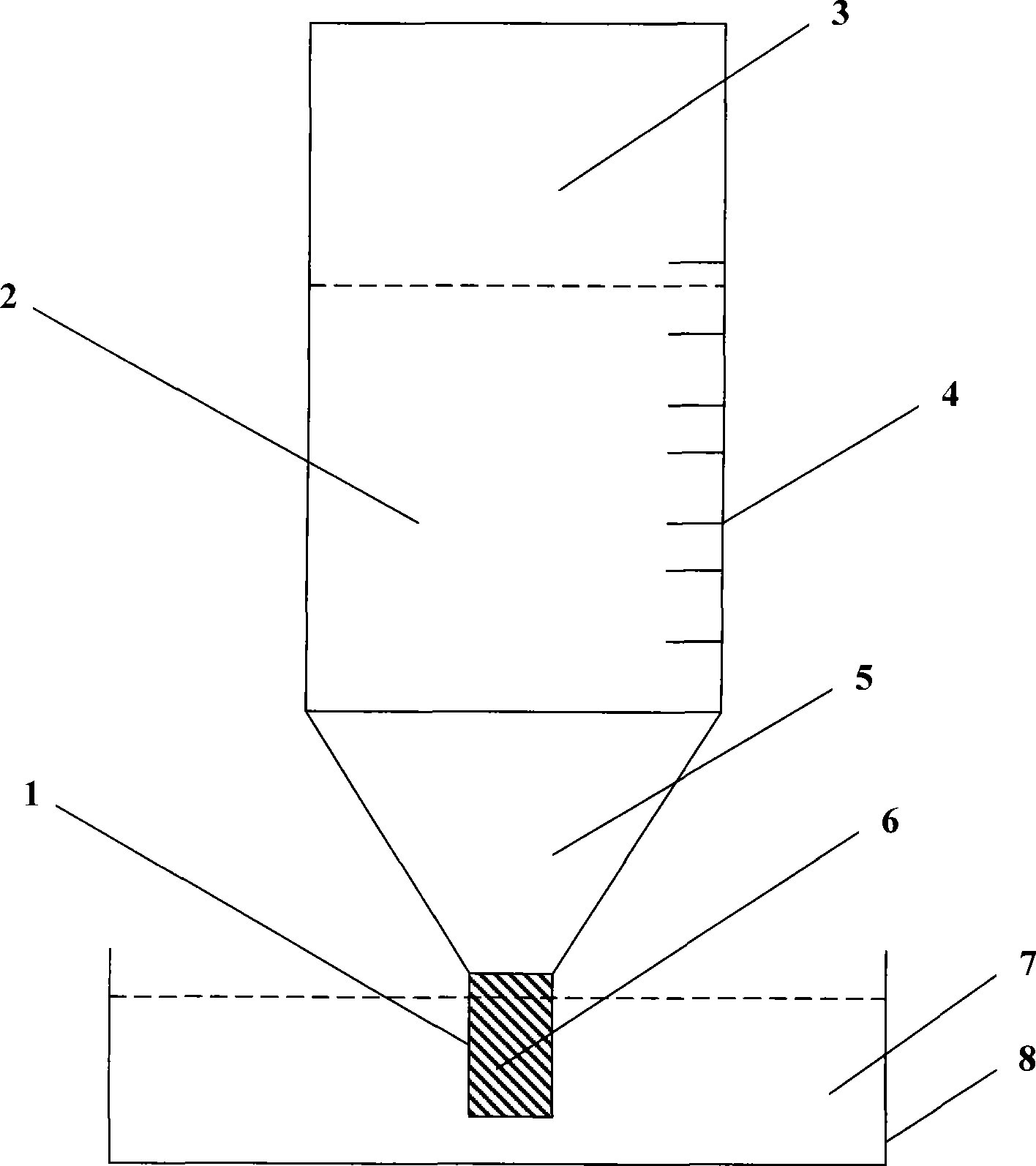

[0015] Embodiment 1: as figure 1 As shown, a vertical temperature gradient solidification and purification device for gallium metal includes three parts: a growth zone 3, a shoulder zone 5, and a seed crystal zone 1. The growth zone 3 is a cylindrical tube, and the shoulder zone 5 is An inverted truncated cone tube connected to the lower end of the growth area 3 , and the seed crystal area 1 is a cylindrical dead tube connected to the lower end of the shoulder area 5 . The seed crystal area 1 is provided with a cooling device, and the cooling device is a cold plate 8 containing a cooling liquid 7 . The purification device is made of non-polar plastic Nylon. The tube wall of the growth zone 3 is provided with a scale line 4 .

[0016] A method for solidifying and purifying metallic gallium with a longitudinal temperature gradient, comprising the following steps: placing metallic gallium seed crystal 6 into the seed crystal region 1; injecting liquid metal gallium 2 into the p...

Embodiment 2

[0017] Embodiment 2: It differs from Embodiment 1 in that the purification device is made of non-polar plastic, the plastic is PE, and the temperature of the liquid gallium metal is 37°C. The cooling temperature of the seed crystal region is 3°C.

Embodiment 3

[0018] Embodiment 3: It differs from Embodiment 1 in that the purification device is made of non-polar plastic Teflon, and the temperature of the liquid gallium metal is 40°C. The cooling temperature of the seed crystal region is 5°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com