Accumulation mounting method for cable sky dome tower frame raising cable rod

An installation method and lifting cable technology are applied to the structure of the dome, the roof, building components, etc., which can solve the problems of reducing the ridge cable, fixing it unchanged, and increasing the workload of installation at high altitude, so as to reduce the distance of traction and facilitate Position and tension, reduce the effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

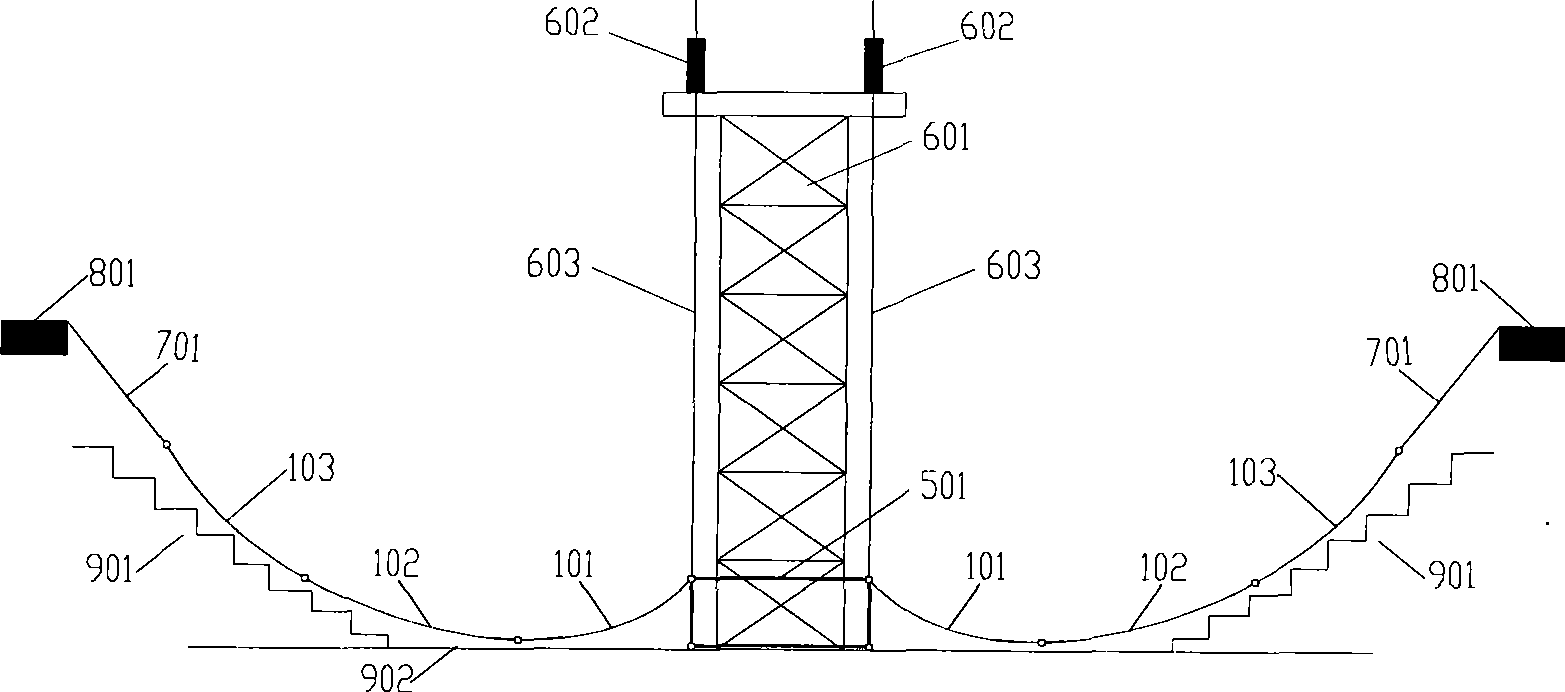

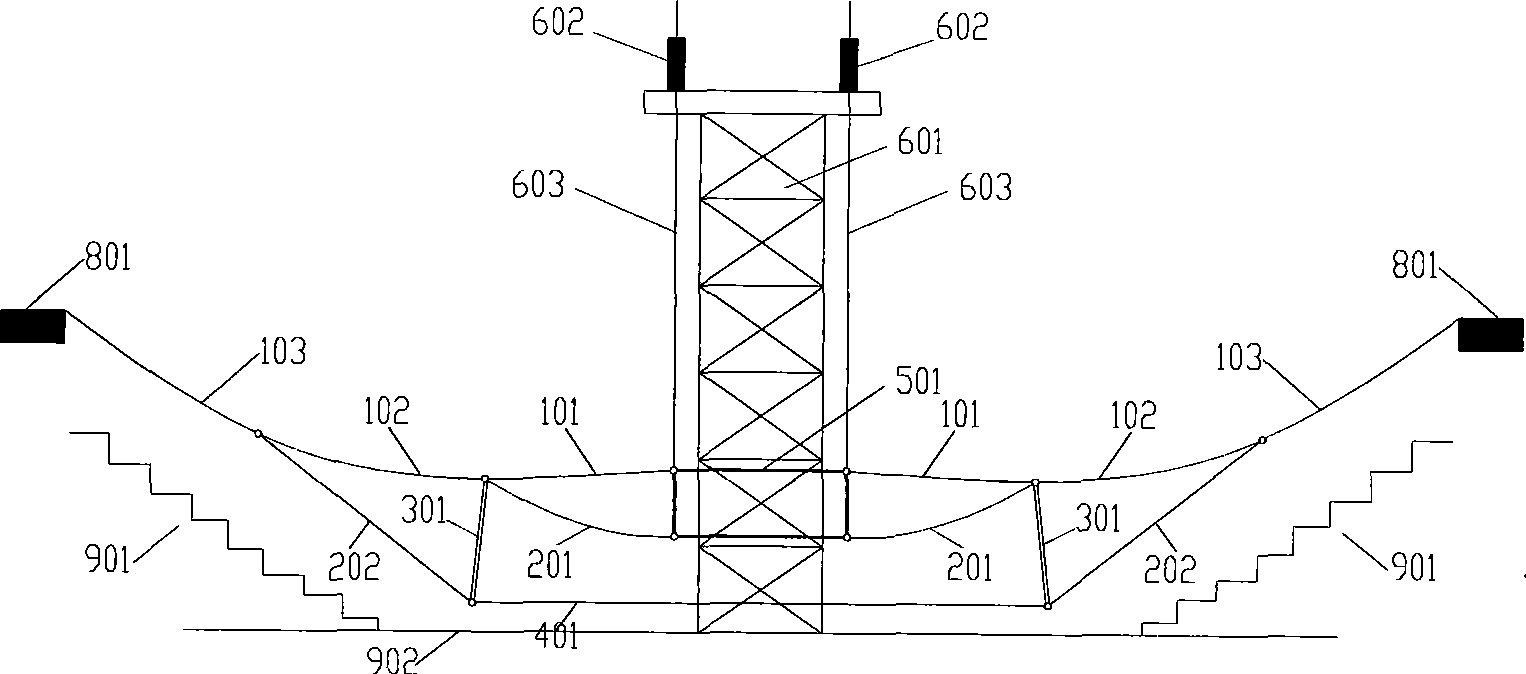

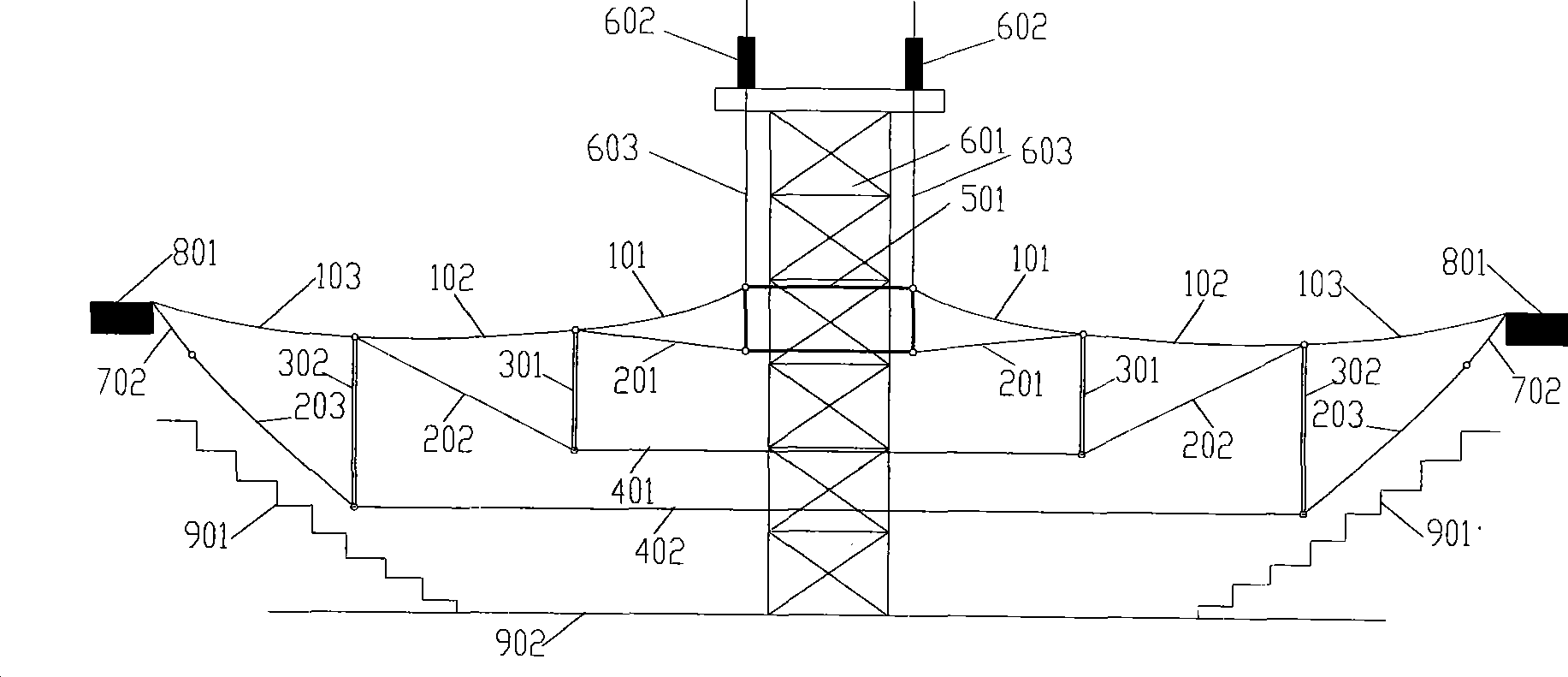

[0024] In the present invention, according to the design elevation of the cable dome and the corresponding position of the central force-bearing member, a lifting tower slightly higher than the design elevation of the apex of the cable dome is set up to uniformly lift the central force-bearing member. At the same time, the entire ridge cable network is also lifted, and then the expansion and cumulative installation of each ring cable, mast and diagonal cable is carried out. The installation sequence of the cable rods can be adjusted according to the distance from the ground or the step surface of each installation point. The height is adjusted, and after all the cables and masts are installed, the outermost ring cable is stretched and formed in stages.

[0025] Specifically, the central load-bearing member 501 is placed on the ground in the center of the site, and the lifting tower 601 and lifting equipment 602 are installed. At the same time, the outer ring ridge cable 103, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com