Middle block fire grate sheet

A grate piece and medium block technology, which is applied in the boiler field, can solve the problems of increasing the labor intensity of the staff grate piece, short service life, and a large number of chain-belt type fire pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

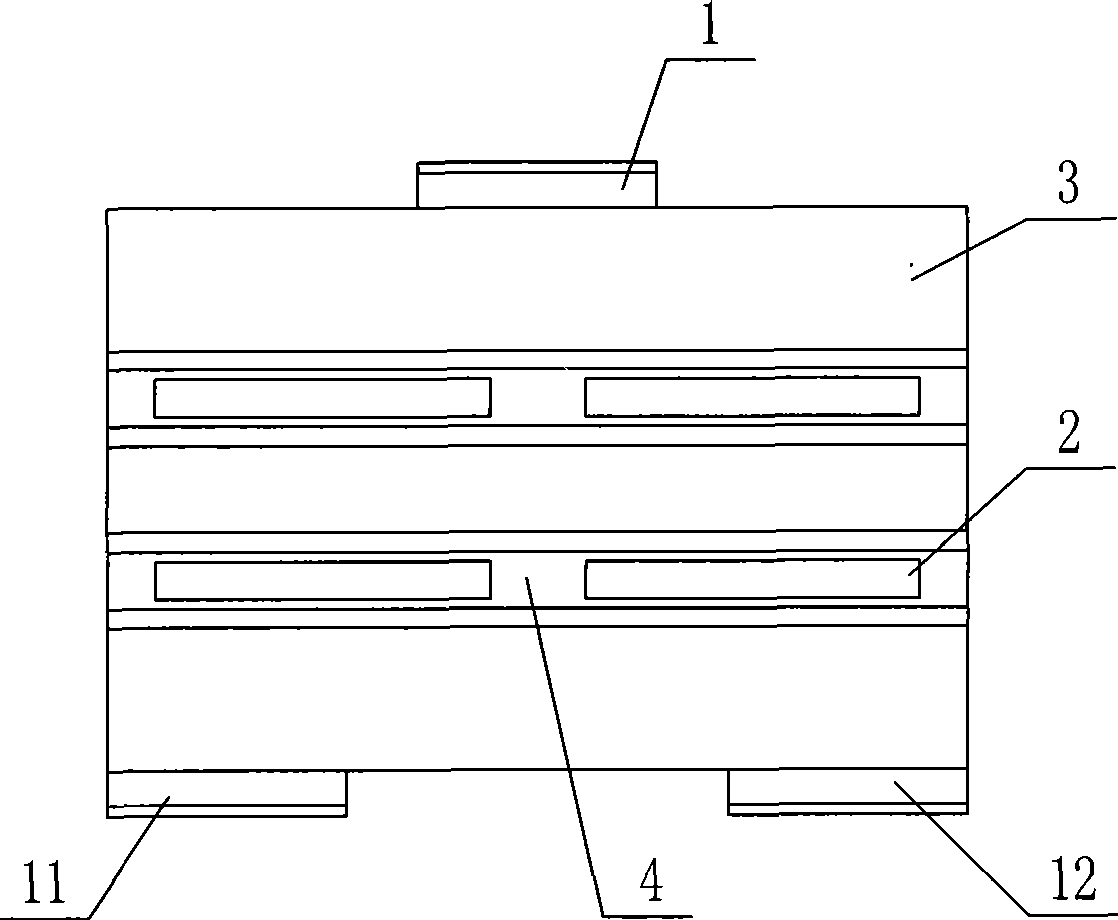

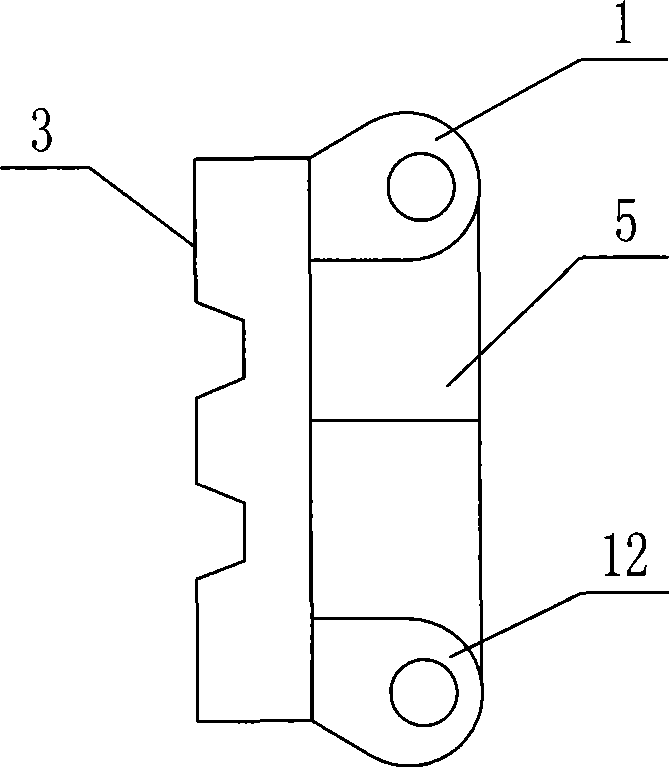

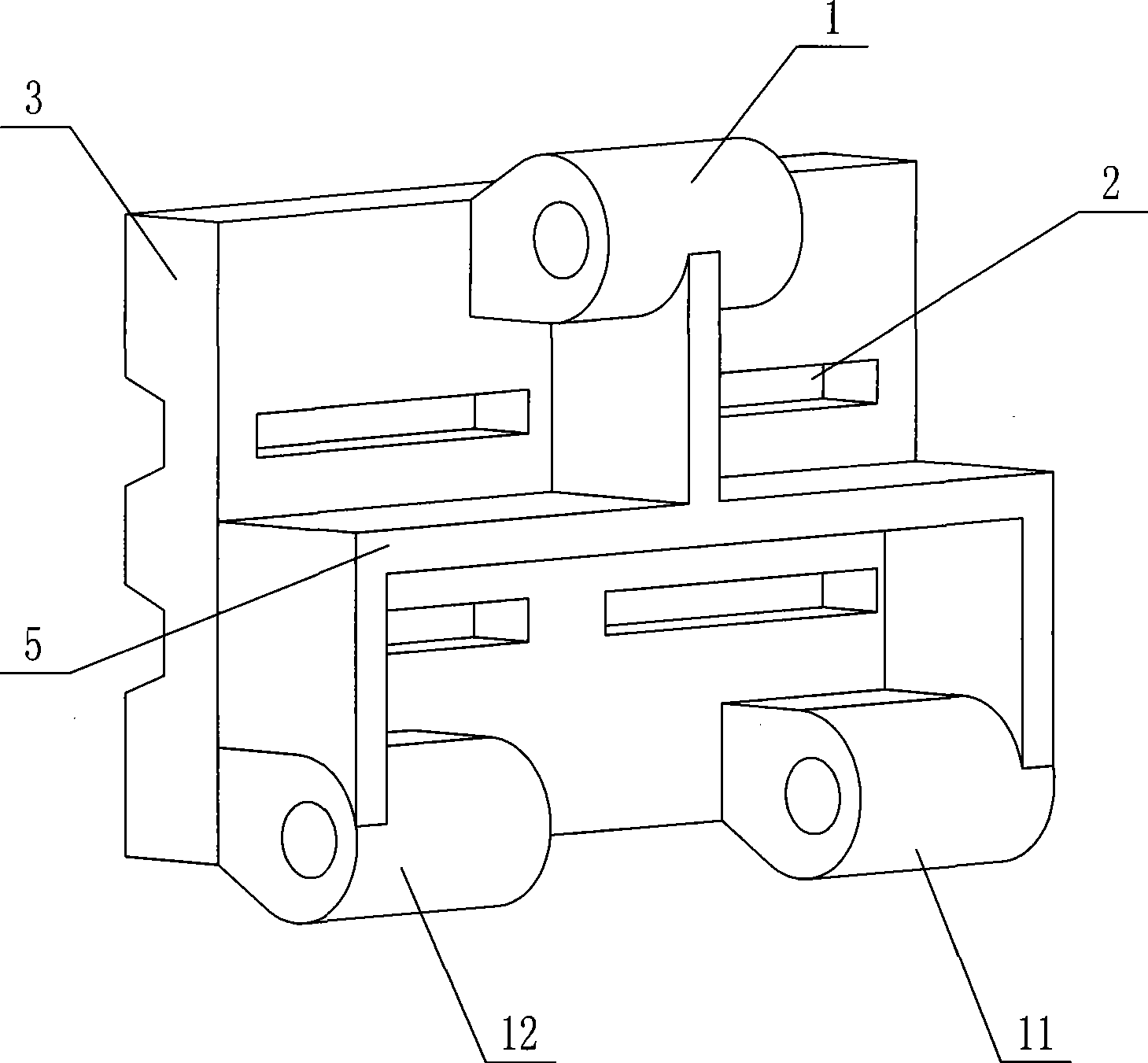

[0013] figure 1 , 2 3. For the middle block grate shown in 3, the combustion surface of the grate frame 3 is provided with 2-4 rows of ventilation grooves 2, the middle of the ventilation grooves is provided with reinforcing ribs 4, and the upper side of the grate frame 3 back is provided with a Connecting sleeve 1, two connecting sleeves 11, 12 are arranged on the lower side of the back, and the two connecting sleeves are placed at both ends, and the three connecting sleeves 1, 11, 12 on the back of the grate frame 3 are connected through the fixing frame 5, and the fixing frame 5 and the grate frame body 3 are cast in one body. The three connecting sleeves are respectively provided with sleeve holes. When installing, among the two adjacent grate pieces connected in series up and down, the upper side connecting sleeve 1 on the lower grate piece extends into the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com